3 Functions Issue 10/06

MICROMASTER 440 Operating Instructions

202 6SE6400-5AW00-0BP0

3.15 Electronic brakes

MICROMASTER 440 has 3 electronic brakes:

DC braking (refer to Section 3.15.1)

Compound braking (refer to Section 3.15.2)

Dynamic braking (refer to Section 3.15.3)

These brakes can actively brake the drive and avoid a possible DC link overvoltage

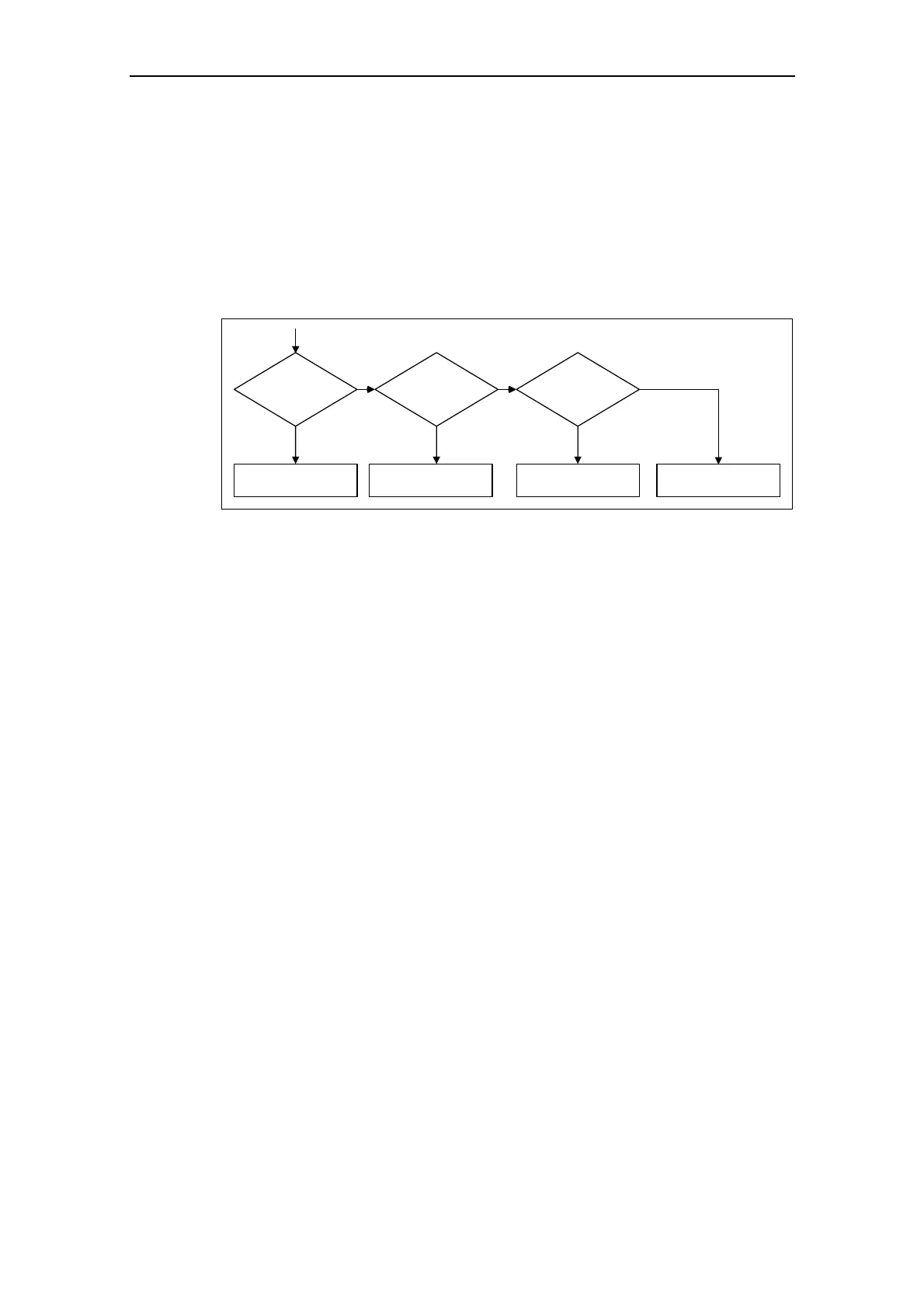

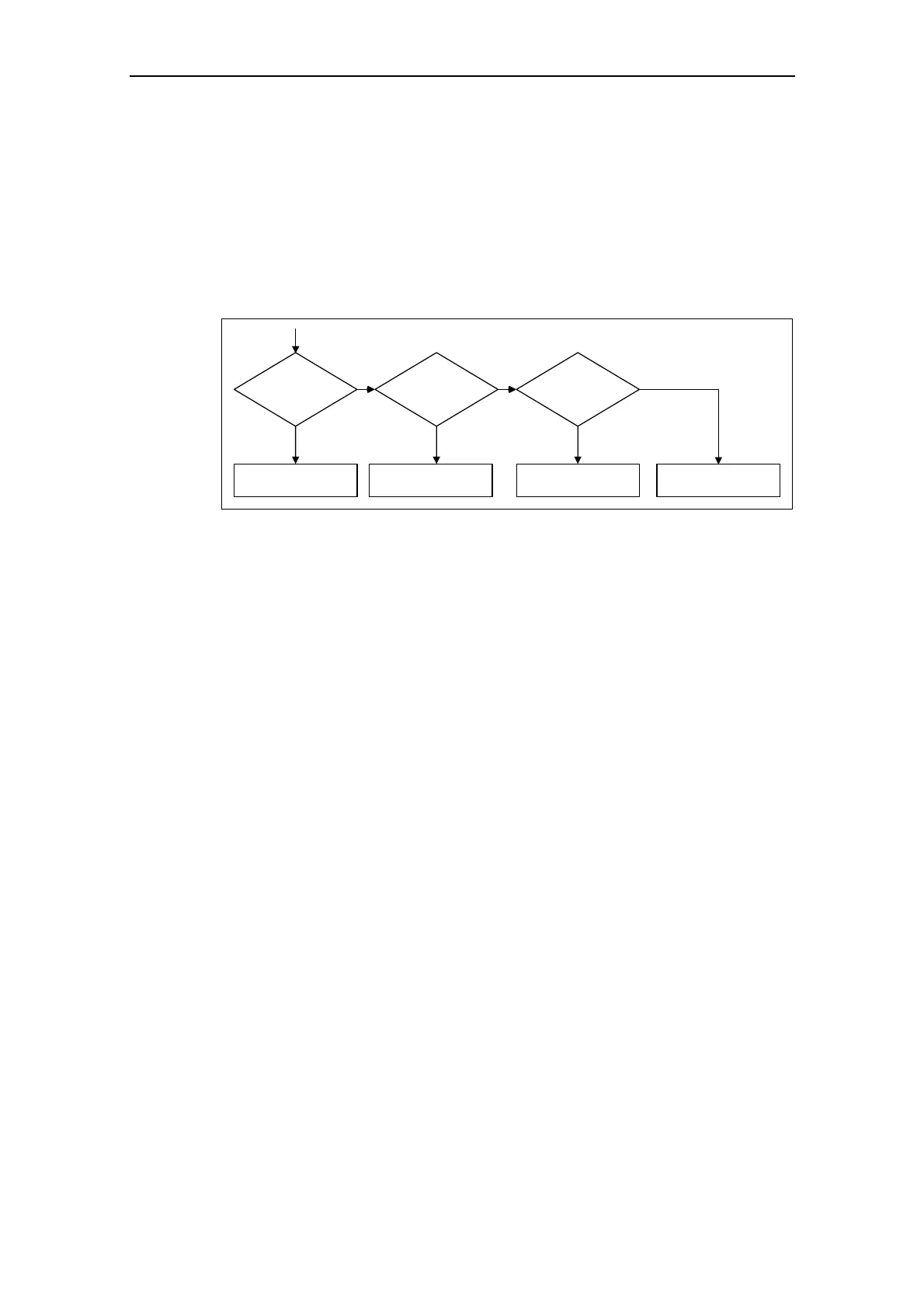

condition. An inter-dependency as shown in Fig. 3-72 is present.

DC braking

P1233 > 0

?

yes

no

DC braking

enabled

Compound

braking

P1236 > 0

?

Compound braking

enabled

Dynamic

braking

P1237 > 0

?

Dynamic braking

enabled

disabled

no no

yes yes

Fig. 3-72 Inter-dependency of the electronic brakes

3.15.1 DC braking

Parameter range: P1230, P1233

P1232, P1234

r0053 Bit00

Warnings -

Faults -

Function chart number: -

The drive decelerates along a parameterized braking ramp if an OFF1 / OFF3

command is output. A "flat" ramp must be selected so that the drive inverter is not

tripped (shutdown) due to the high regenerative energy which would cause a DC

link overvoltage condition. The DC brake should be activated while the OFF1 /

OFF3 command is present if the drive is to be braked faster. For DC braking,

instead of continually reducing the output frequency / voltage during the OFF1 /

OFF3 phase, from a selectable frequency, a DC voltage / current is input (refer to

sequence a).

The drive can be brought to a standstill in the shortest time using DC current

braking (DC brake). DC braking is selected as follows:

¾ After OFF1 or OFF3 (the DC brake is released via P1233) Sequence ℵ

¾ Directly selected using BICO parameter P1230 Sequence ℑ

For DC braking, a DC current is impressed in the stator winding which results in a

significant braking torque for an induction motor. The magnitude, duration and

frequency at which braking starts can be set for the braking current and therefore

braking torque by setting the appropriate parameters.

Loading...

Loading...