3 Functions Issue 10/06

MICROMASTER 440 Operating Instructions

80 6SE6400-5AW00-0BP0

By changing the setting of DIP50/60 switch, after the drive inverter has been

powered-down/powered-up, the parameters for the rated motor frequency P0310,

max. frequency P1082 and reference frequency P2000 are automatically pre-set.

In addition, the rated motor parameters as well as all of the other parameters which

depend on the rated motor parameters, are reset. The units of the power

parameters are, depending on P0100, are either interpreted as kW value or hp

value.

NOTE

Switch DIP2(1) (refer to Fig. 3-21) under the I/O board has no function.

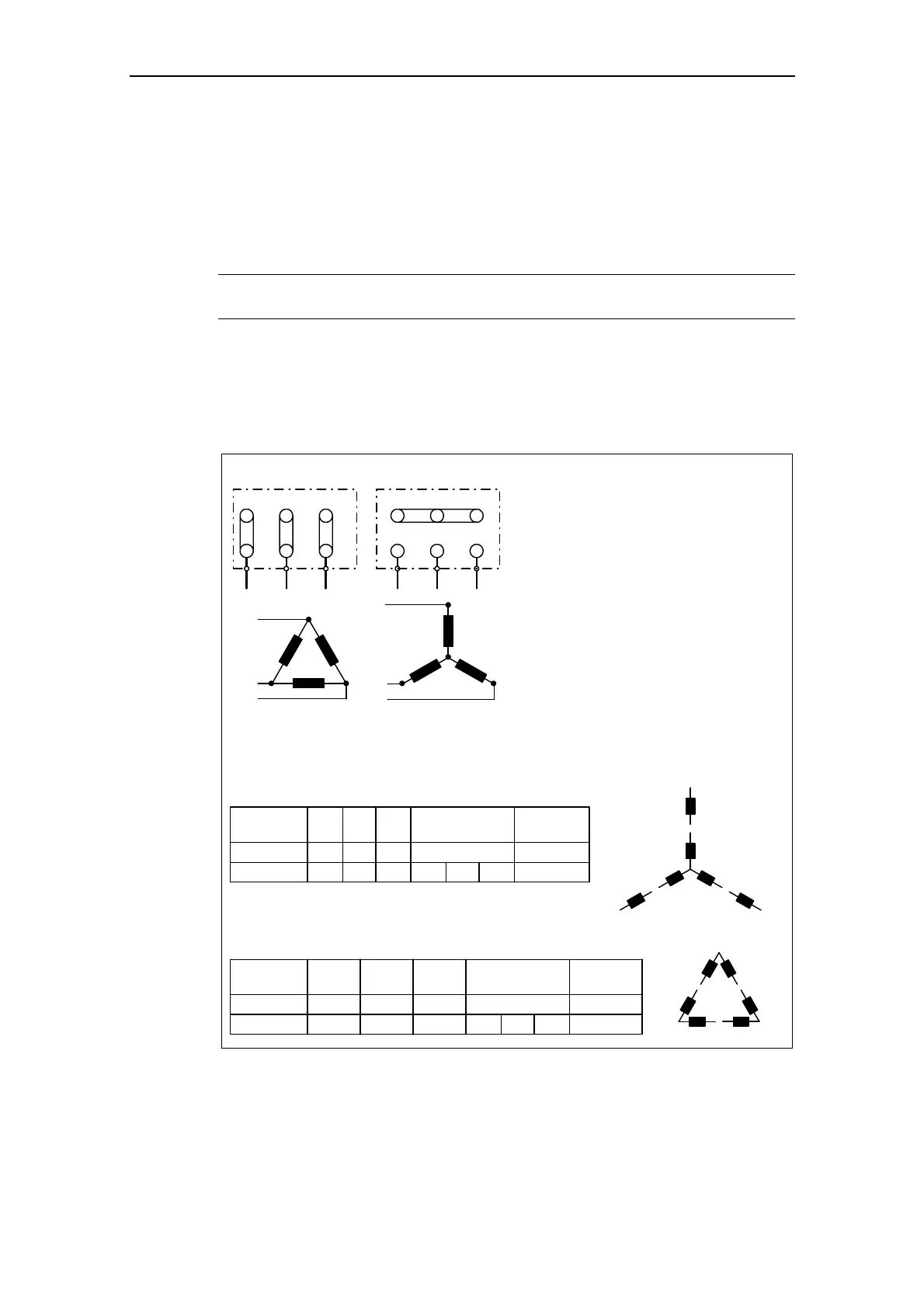

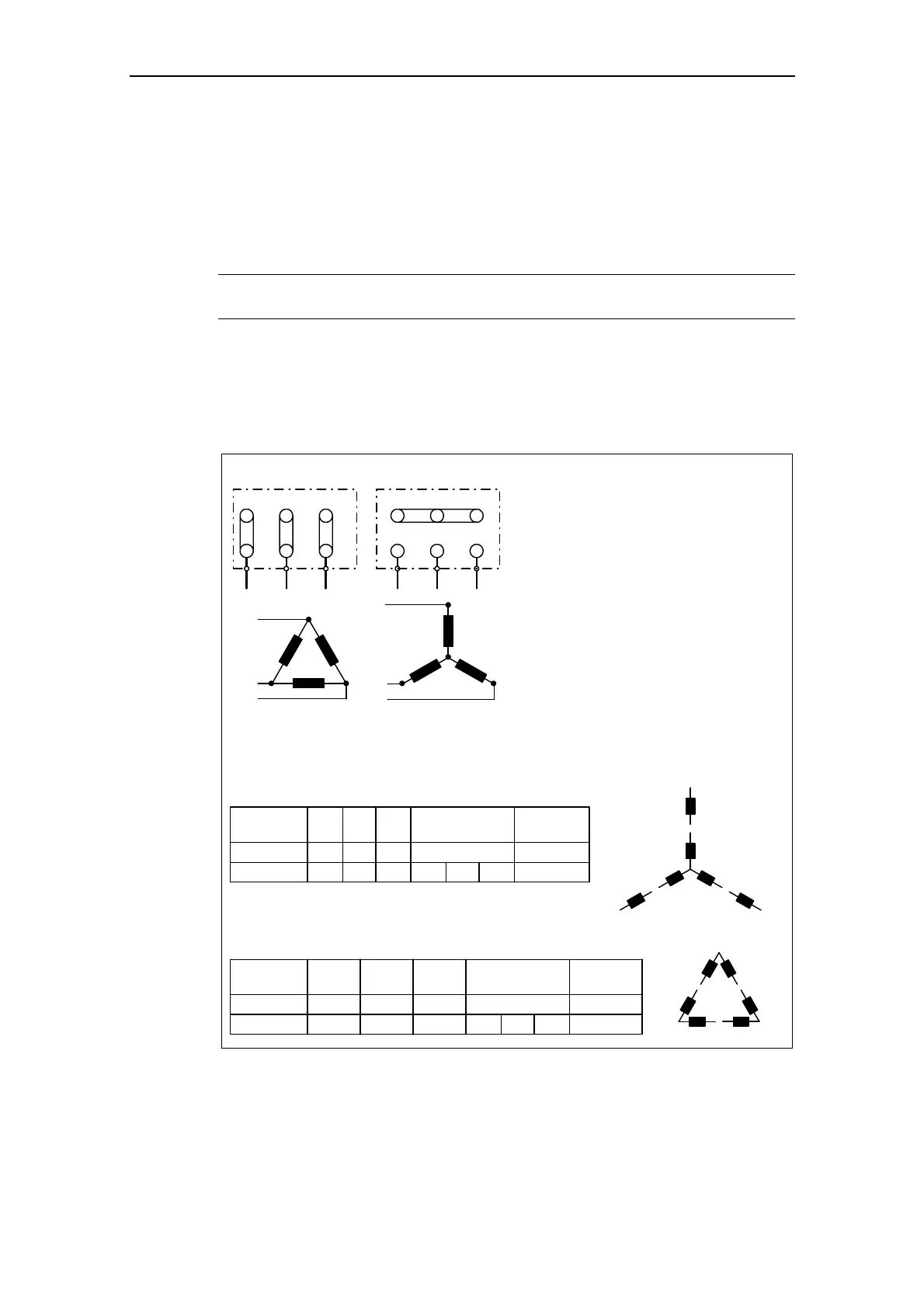

3.5.2 Motor circuit

In order to ensure a straightforward, successful commissioning, it is important that

the circuit connection in the motor terminal box (refer to Fig. 3-23) matches the

rated motor voltage entered in P0304 or the rated motor current P0305.

W2

U1

U2

V1

V2

W1

W2

U1

U2

V1

V2

W1

Delta connection

U1

V1

W1

U1

V1

W1

Star connection

IEC Motor

e.g.: Volts 230 V (Delta connection) / 400 V (Star connection)

NEMA Motor

T

1

T

4

T

7

T

3

T

6

T

9

T

8

T

5

T

2

Volts

UVW

T

1

-T

7

T

2

-T

8

T

3

-T

9

low

T

4

-T

5

-T

6

T

1

T

2

T

3

high

Connected

together

Connection

T

1

-T

7

T

2

-T

8

T

3

-T

9

Y Y

Y

UVW

T

1

-T

6

-T

7

T

2

-T

4

-T

8

T

3

-T

5

-T

9

-

T

1

T

2

T

3

T

4

-T

7

T

5

-T

8

T

6

-T

9

∆ ∆

∆

T

1

T

4

T

7

T

2

T

5

T

8

T

3

T

9

T

6

e.g.: Volts 230 V YY (low) / 460 V Y (high)

Volts

low

high

Connected

together

Connection

Fig. 3-23 Motor terminal box

Loading...

Loading...