Function description

Select one of the application classes or setting "Expert":

•

Standard Drive Control (Page128)

• Dynamic Drive Control (Page130)

• Expert (Page133)

Application class Standard Drive Control Dynamic Drive Control

Motors that can

be operated

Induction motors Induction and synchronous motors

Application exam‐

ples

• Pumps, fans, and compressors with ow char‐

acteristic

• Wet or dry blasting technology

• Mills, mixers, kneaders, crushers, agitators

• Horizontal conveyor technology (conveyor

belts, roller conveyors, chain conveyors)

• Basic spindles

• Pumps and compressors with displacement ma‐

chines

• Rotary furnaces

• Extruder

• Centrifuges

Properties

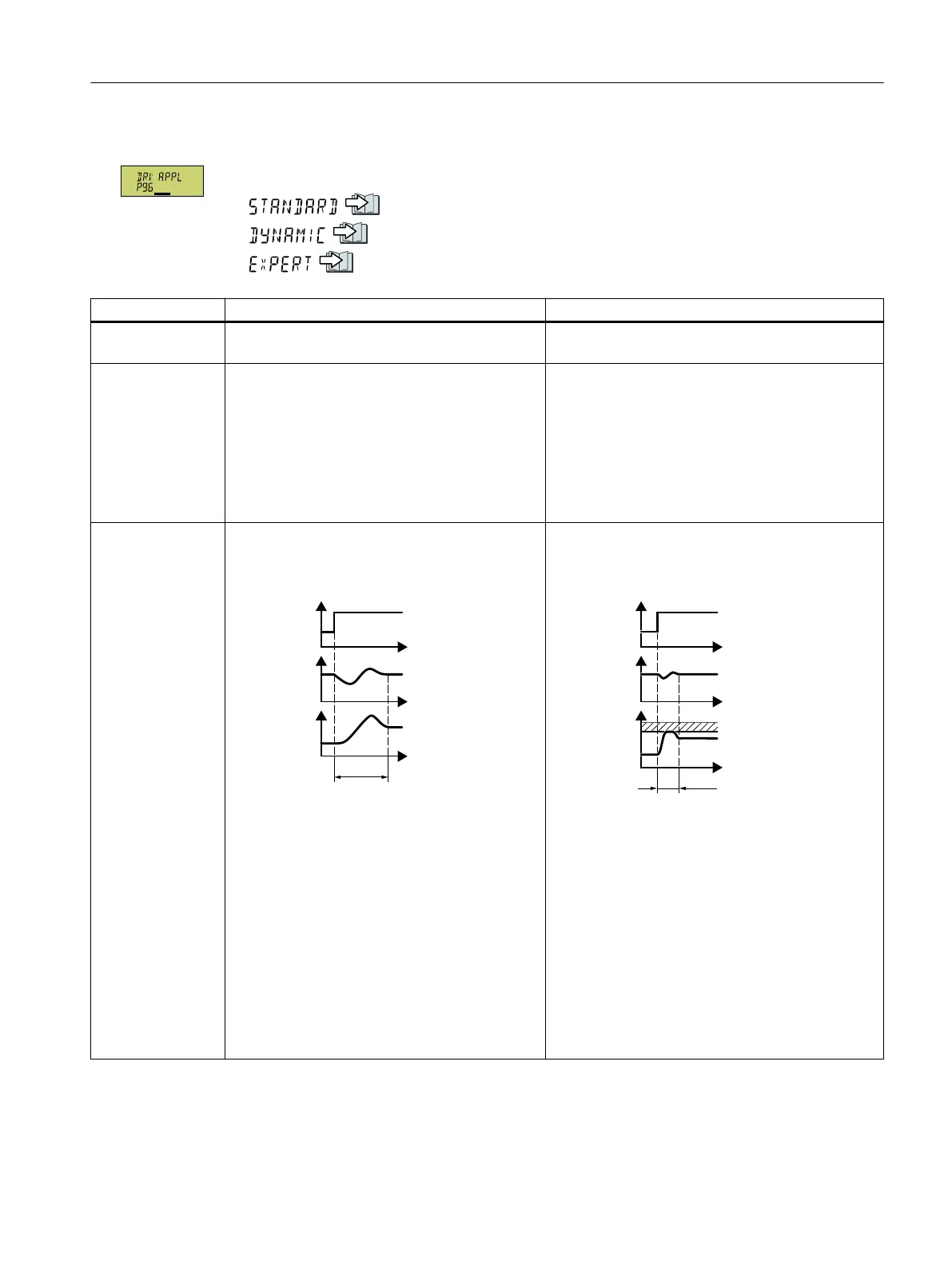

• Typical settling time after a speed change:

100ms…200ms

• Typical settling time after a load surge: 500 ms

6SHHG

/RDG

0RWRU

WRUTXH

W

W

W

PV

• "Standard Drive Control" is suitable to address

the following requirements:

– All motor power ratings

– Ramp-up time 0→rated speed (depend‐

ing on the motor power rating):

1s(0.1kW)…10s(45kW)

– Applications with steady load torque with‐

out load surges

• "Standard Drive Control" is insensitive with re‐

spect to imprecise setting of the motor data

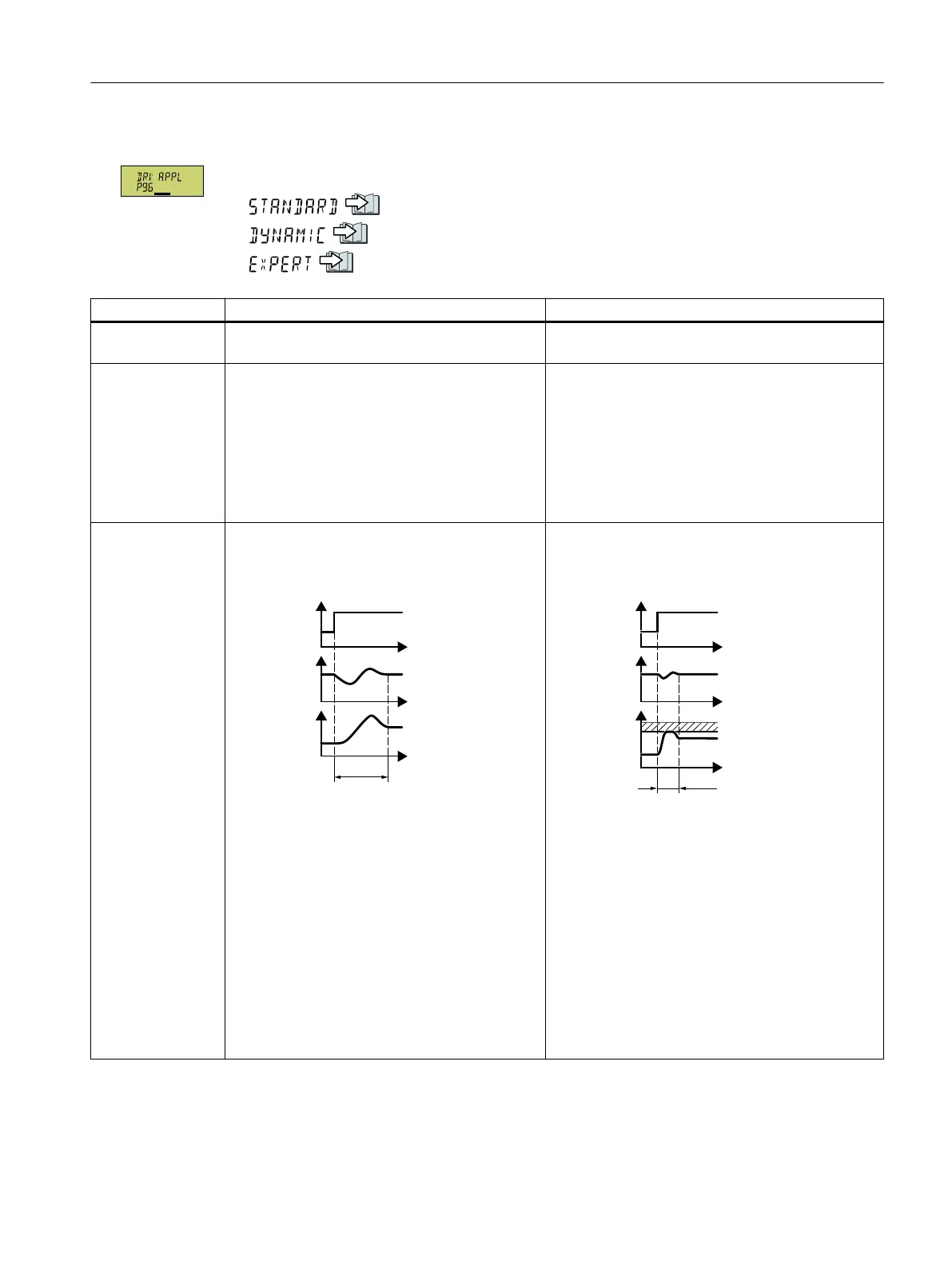

• Typical settling time after a speed change:

<100ms

• Typical settling time after a load surge: 200ms

6SHHG

/RDG

0RWRU

WRUTXH

W

W

PV

• "Dynamic Drive Control" controls and limits the

motor torque

• Typically achieves a torque accuracy: ±5% for

15%… 100% of the rated speed

• We recommend "Dynamic Drive Control" for the

following applications:

– Motor power ratings >11kW

– For load surges 10%…>100% of the rated

motor torque

• "Dynamic Drive Control" is necessary for a ramp-

up time 0 → rated speed (dependent on the rated

motor power): < 1 s (0.1 kW) … < 10 s (132 kW).

Commissioning

5.4Quick commissioning using the BOP-2 operator panel

SINAMICS G120C Converters

Operating Instructions, 02/2023, FW V4.7 SP14, A5E34263257B AK 127

Loading...

Loading...