I

•NTENSITY

I

Vertical

Chopped

Blanking Signal

from Vertical Switching

Circuit

External Blanking

from Z

AXIS

INPUT

Connector

A

and

B

unblanking

gate

from

Sweep

Generator

circuits

R1005

R1004

R1011

R1012

C1036

Circuit

Description-Type

453/R453

+

90

V to

r------"~

Geometry

Adjustment

Unblanking

gate

to

CRT

circuit

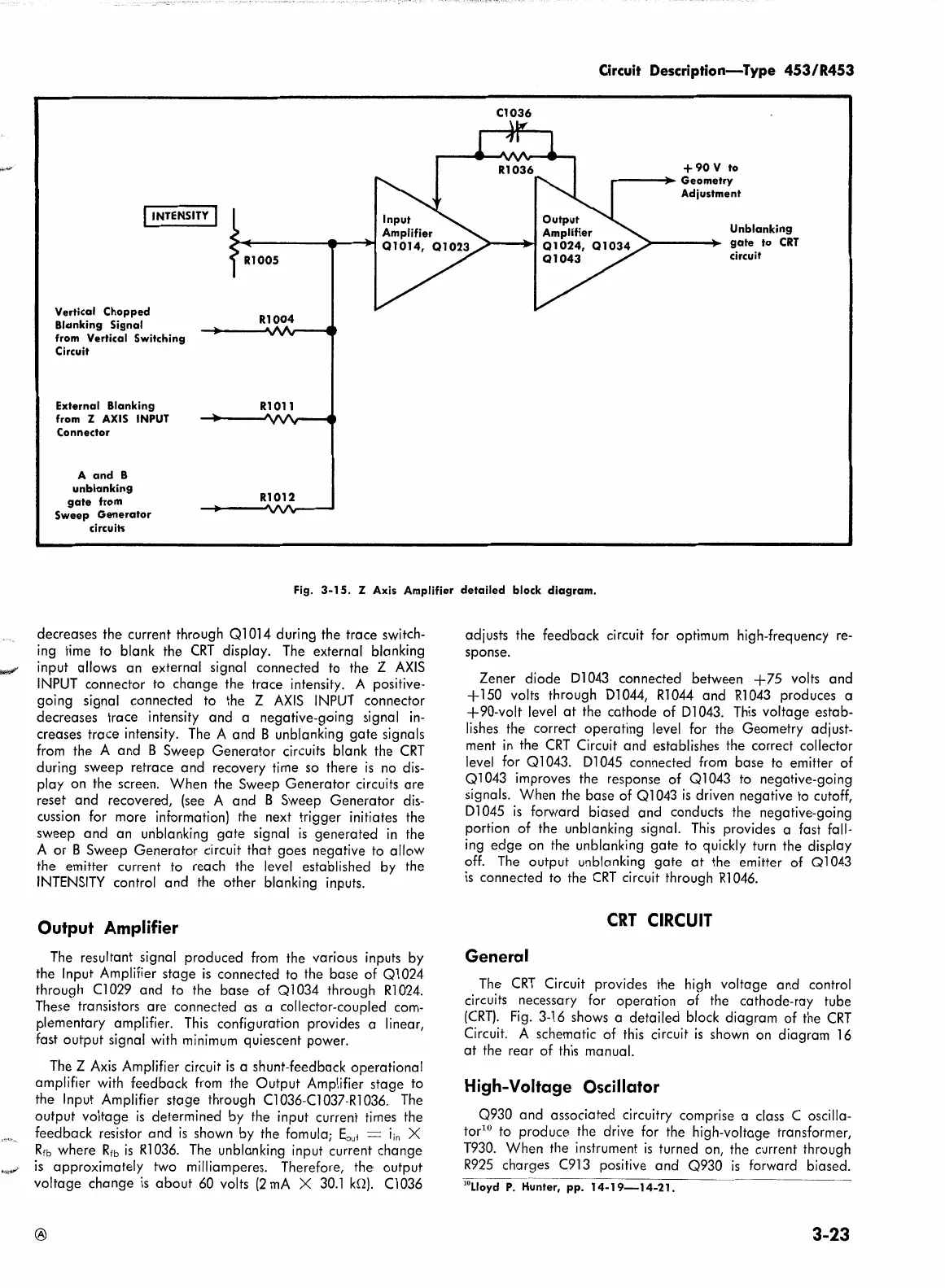

Fig.

3-15.

Z Axis Amplifier

detailed

block

diagram.

decreases the current through

Ql

014

during the trace switch-

ing time to blank the

CRT

display.

The

external blanking

input allows an external signal connected to the Z

AXIS

INPUT

connector to change the trace intensity. A positive-

going signal connected to the Z

AXIS

INPUT

connector

decreases trace intensity and a negative-going signal

in-

creases trace intensity.

The

A and B unblanking

gate

signals

from

the A and B Sweep Generator circuits blank the

CRT

during sweep retrace and recovery time

so

there

is

no

dis-

play on the screen. When the Sweep Generator circuits

are

reset and recovered,

(see

A and B Sweep Generator dis-

cussion for more information) the next trigger initiates the

sweep and an unblanking gate signal

is

generated

in

the

A or B Sweep Generator circuit that goes negative to allow

the emitter current to reach the

level

established by the

INTENSITY

control and the other blanking inputs.

Output

Amplifier

The

resultant signal produced

from

the various inputs by

the Input Amplifier stage

is

connected to the base of

Ql

024

through

Cl

029

and to the base of

Ql

034 through

Rl

024.

These transistors are connected as a collector-coupled

com-

plementary amplifier.

This

configuration provides a linear,

fast output signal

with

minimum

quiescent power.

The

Z

Axis

Amplifier circuit

is

a shunt-feedback operational

amplifier

with

feedback

from

the Output Amplifier stage to

the Input Amplifier stage through

Cl

036-Cl

037-Rl

036.

The

output voltage

is

determined by the input current

times

the

feedback resistor and

is

shown by the fomula· E t -

i·

X

Rtb

where

Rtb

is

Rl

036.

The

unblanking input

~ur~uen~h~nge

is

approximately two milliamperes. Therefore, the output

voltage change

is

about

60

volts

(2

mA

X

30.

l kn).

Cl

036

®

adjusts the feedback circuit for optimum high-frequency

re-

sponse.

Zener diode

Dl

043

conneded between

+75

volts and

+

150

volts through

Dl

044,

Rl

044 and

Rl

043

produces a

+90-volt

level

at

the cathode of

Dl

043.

This

voltage estab-

lishes

the correct operating

level

for the Geometry adjust-

ment

in

the

CRT

Circuit and establishes the correct collector

level

for

Ql

043.

Dl

045 connected

from

base to emitter of

<?1043

improves the response of Ql043

to

negative-going

signals. When the base of

Ql

043

is

driven negative

to

cutoff,

Dl

045

is

forward biased and conducts the negative-going

portion of the unblanking signal.

This

provides a fast fall-

ing

edge

on

the unblanking gate

to

quickly turn the display

off.

The

output unblanking gate

at

the emitter of

Ql

043

is

connected to the

CRT

circuit through

Rl

046.

CRT

CIRCUIT

General

The

CRT

Circuit provides the

high

voltage and control

circuits necessary for operation of the cathode-ray tube

(CRT).

Fig.

3-16 shows a detailed block diagram of the

CRT

Circuit. A schematic of

this

circuit

is

shown

on

diagram

16

at

the rear of

this

manual.

High-Voltage Oscillator

0930

and associated circuitry comprise a class C oscilla-

tor10

to produce the drive for the high-voltage transformer,

T930.

When the instrument

is

turned

on,

the current through

R925

charges

C913

positive and Q930

is

forward biased.

10

Lloyd

P.

Hunter,

pp.

14-19-14-21.

3-23

Loading...

Loading...