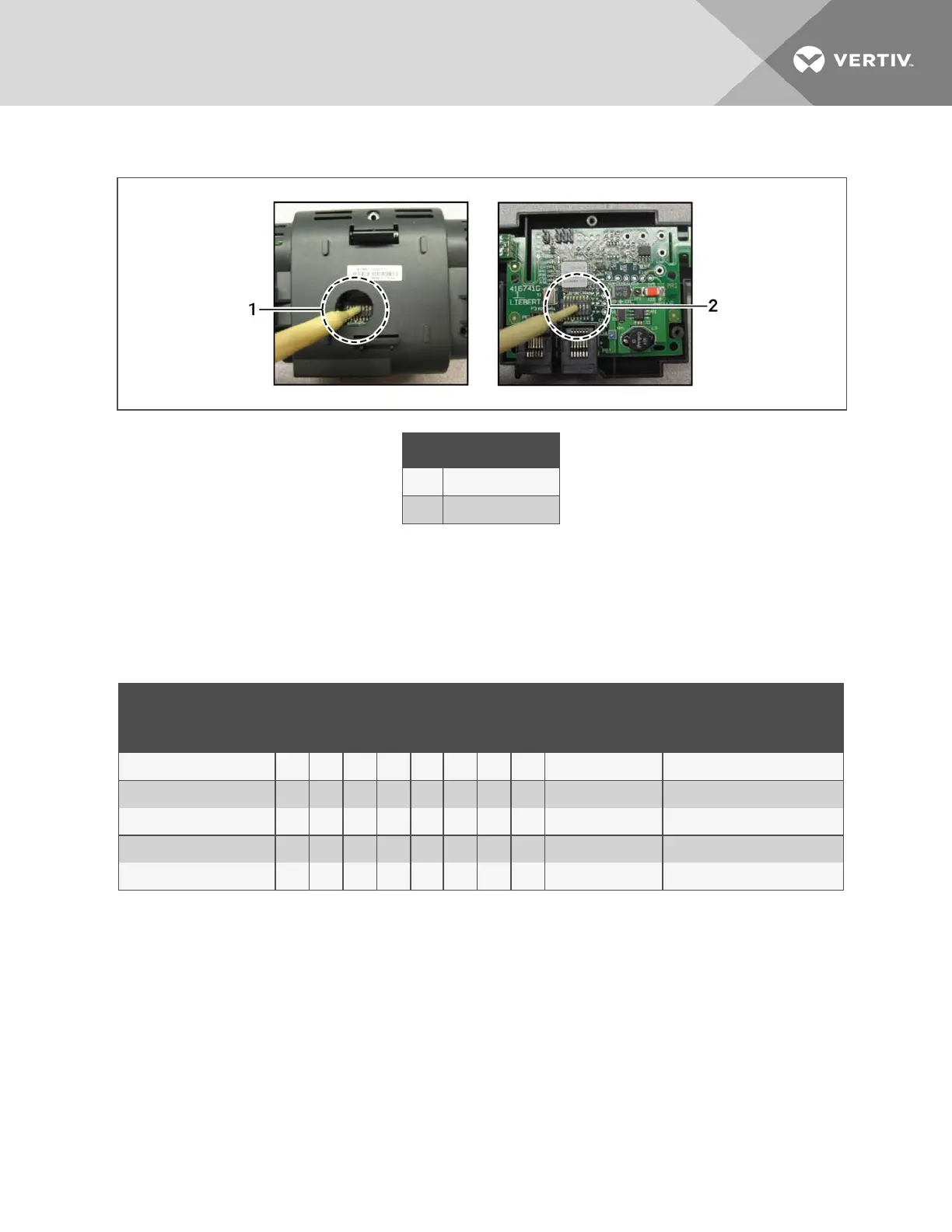

Figure 12.16 DIP Switch Opening/DIP Switches Inside of 2T Sensor

Item Description

1 Hole in sensor housing

2 Cover removed

3. Referring to Table 12.4 below, and using the non-conductive tool, set the DIP switches for each sensor to its

number in the chain (from sticker applied in step 1).

Figure 12.17 on the next page, shows a representation of the DIP switches.

4. Confirm that the DIP switches are set correctly for each sensor, and replace the housing cover if necessary.

Sensor Number/Address

DIP Switch Position

CANbus Node ID Alternate Use

1 2 3 4 5 6 7 8

A On Off Off Off On Off Off Off 17 Temperature/Humidity

B Off On Off Off On Off Off Off 18 Temperature/Humidity

C On On Off Off On Off Off Off 19 Temperature/Humidity

D Off On On On On Off Off Off 30 Fluid inlet/outlet temperature

E On On On On On Off Off Off 31 Fluid inlet/outlet temperature

Table 12.4 DIP Switch Settings for Supply Air Aggregation Sensors

13 Hardware Installation

123