5-4

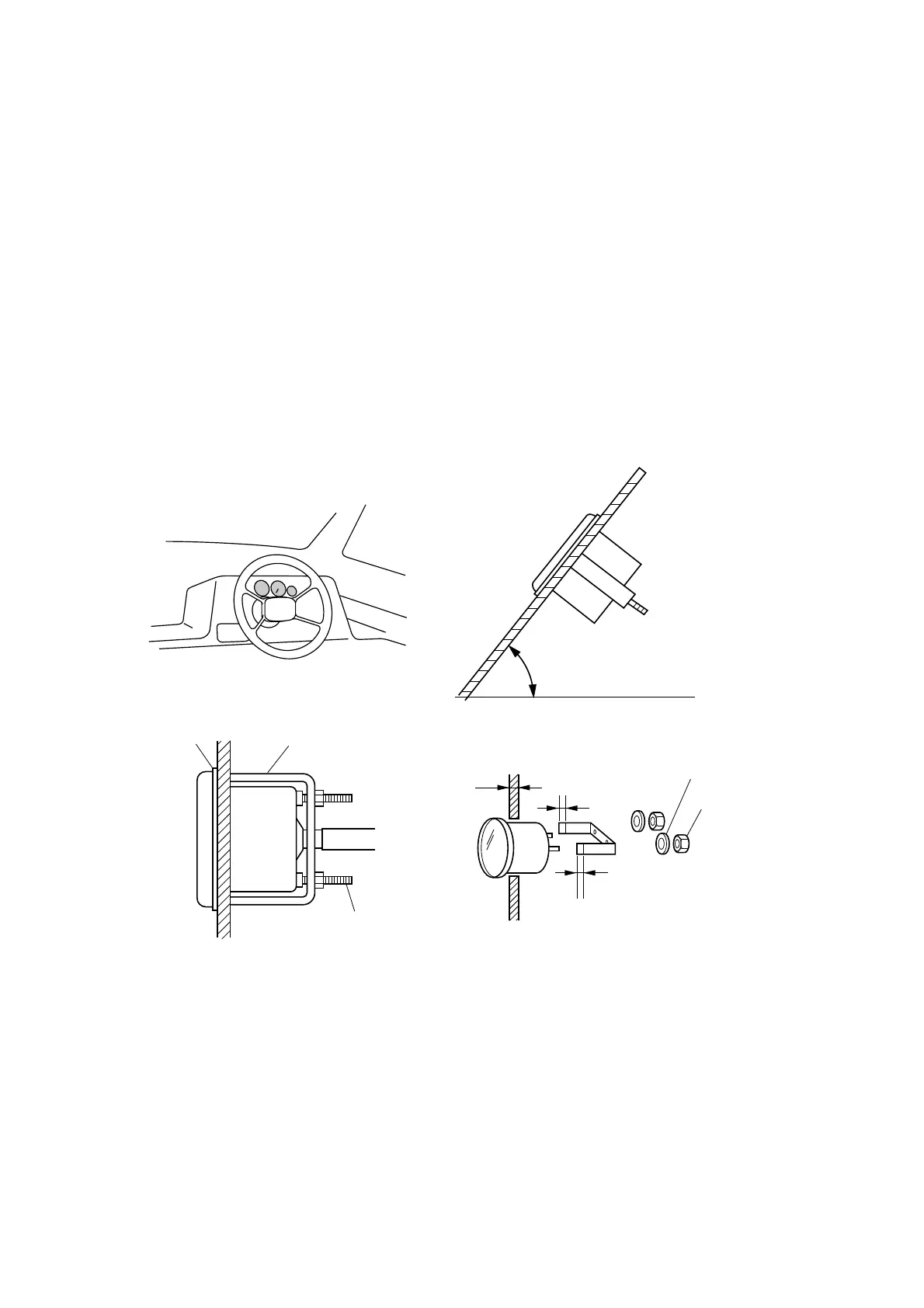

MOUNTING THE METERS

The meters can be installed to electrical start models because power source is required for the

operation.

METER MOUNTING PROCEDURE

Follow the procedures below for mounting the gauges.

1. Select a mounting location so that the meter is easy to read from the operating position.

Be sure that there is sufficient clearance behind the panel for the meter.

For analog meters, be sure that the angle for mounting the meter is 65 to 90 degrees.

If the analog gauge is mounted onto horizontal surface, the pointer may not return to the zero po-

sition after the engine has stopped.

2. Make a hole at the desired position.

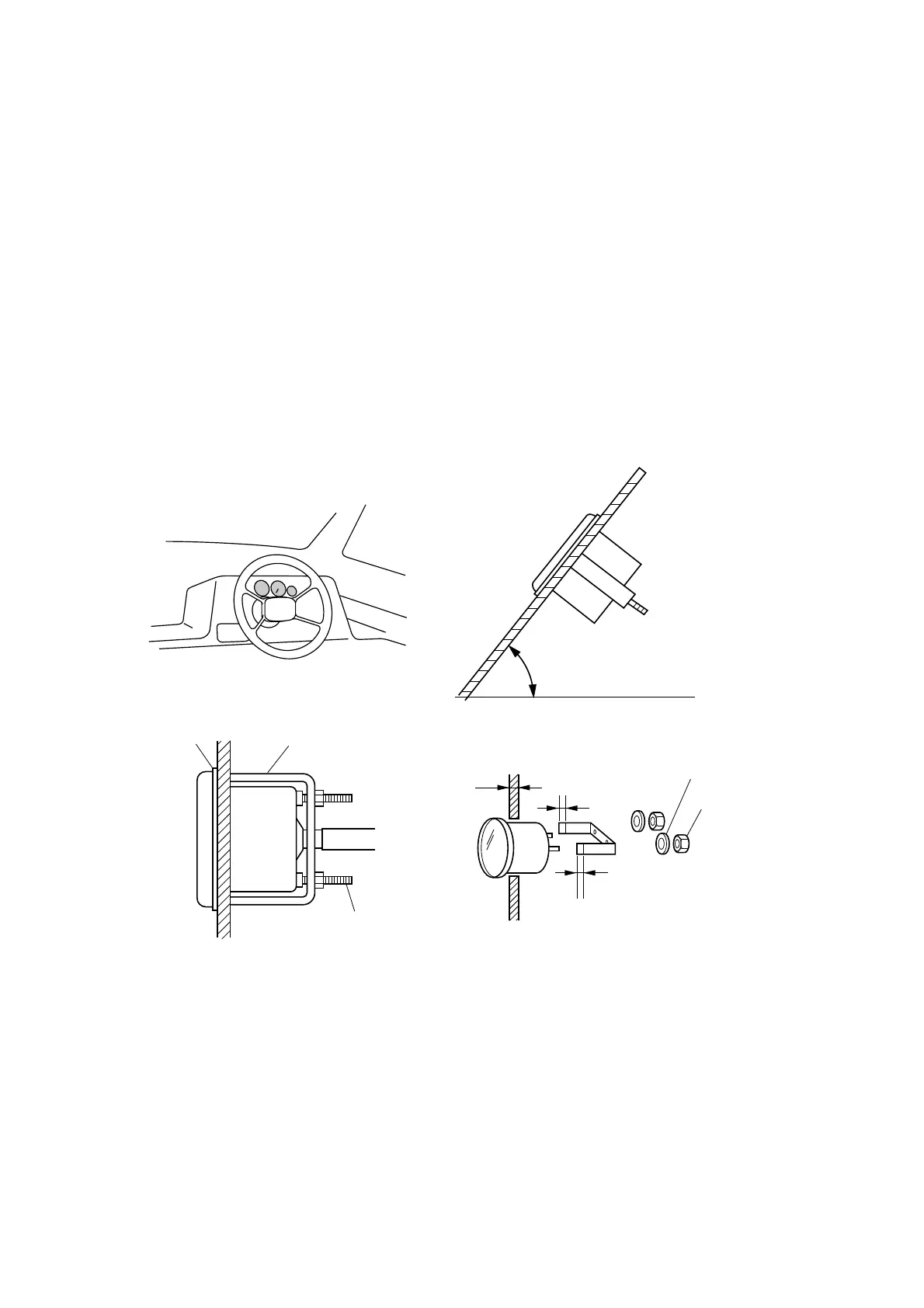

3. Remove the fitting plate from the meter, fit the meter into the panel, and install the fitting plate

over the mounting studs.

4. Place the washers over the studs, and then evenly tighten the mounting nuts until the meter can

no longer be rotated by hand.

5. Connect the wire-harnesses to the gauges, and secure them into a boat.

* If the gauge is mounted onto a 13 mm (0.5 in) or thicker board, cut out the fitting plate end so that the mount

nut is enough tightened.

ANALOG GAUGE ILLUMINATION (6Y7 TYPE)

For black-face analog gauge, the faceplate is illuminated with permeation light for nighttime opera-

tion.

The white-face analog gauge used an indirect clear lighting.

65˚ – 90˚

[Analog meter]

Gasket Fitting plate

Panel

thickness

Cutting area

(for thicker panel)

Nut

Wave washer

Mounting stud

Loading...

Loading...