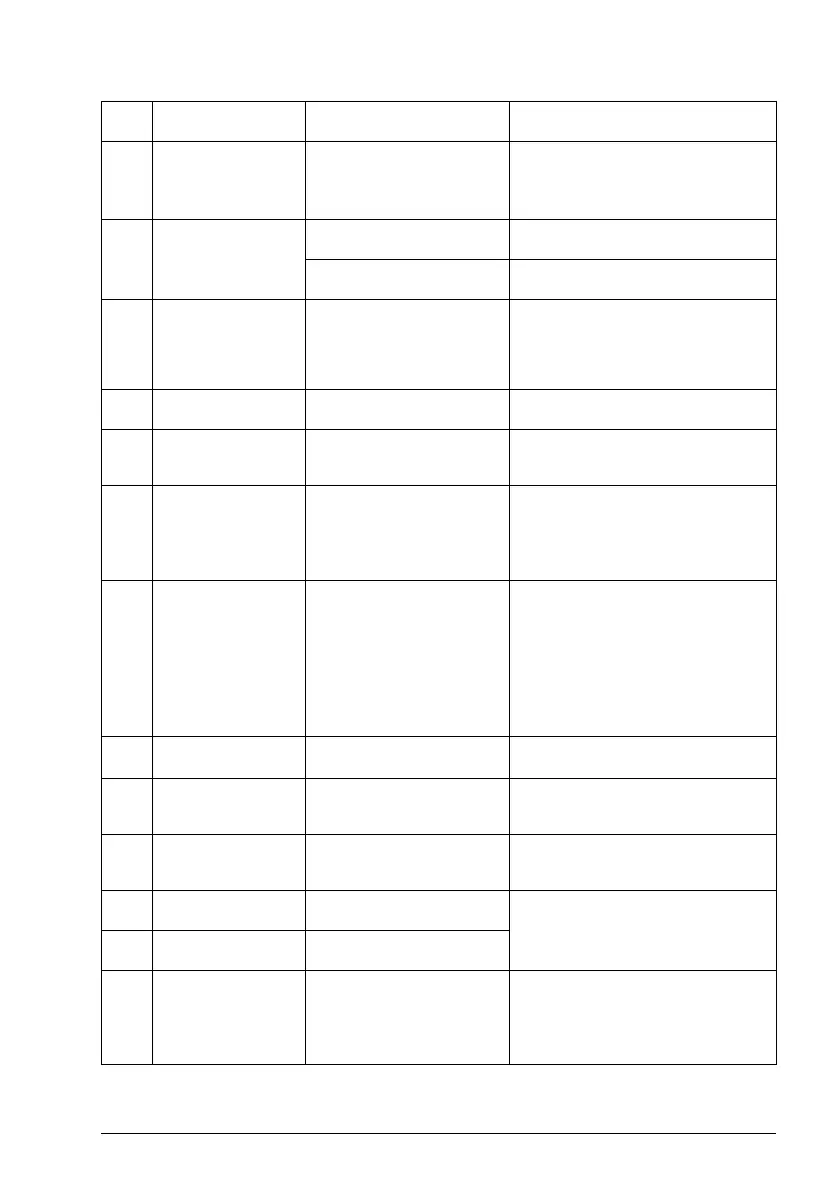

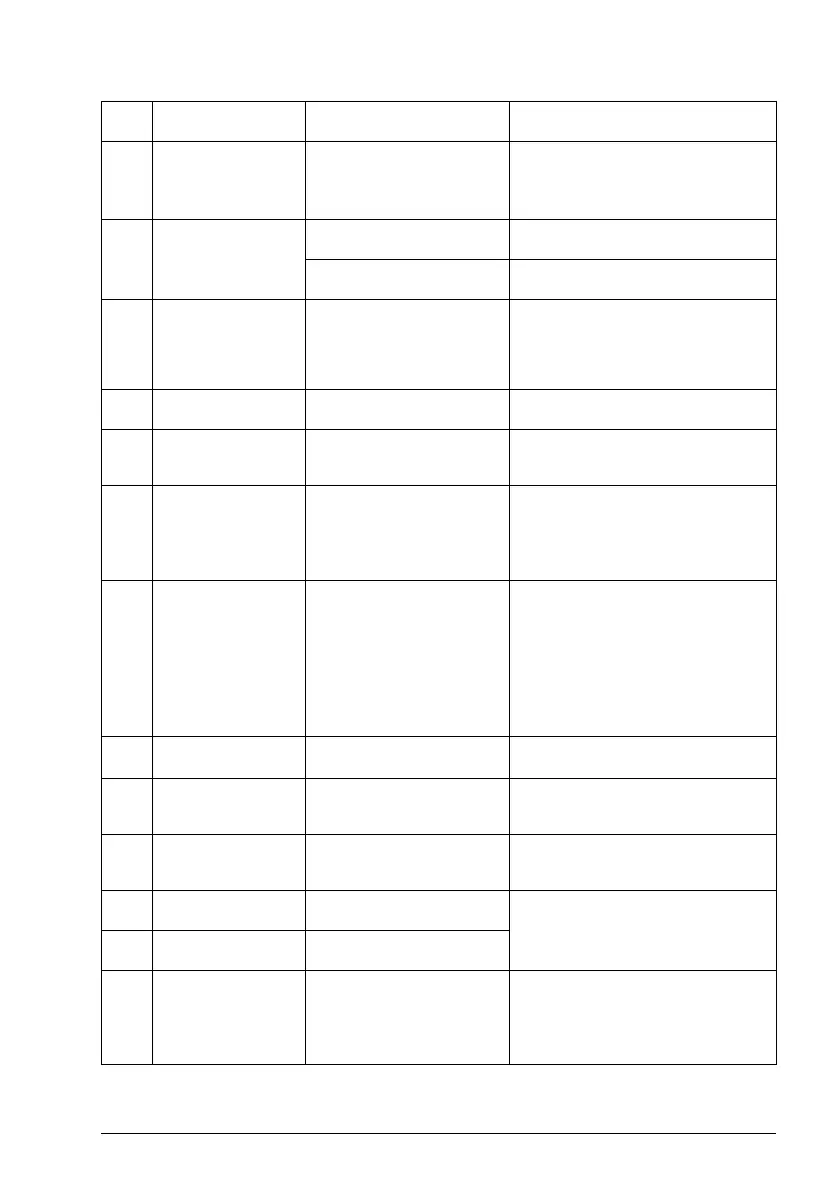

Fault tracing 337

A687 Checksum

configuration

An action has been defined for

a parameter checksum

mismatch but the feature has

not been configured.

Contact your local ABB representative for

configuring the feature, or disable the

feature in 96.54 Checksum action.

A6A4 Motor nominal value The motor parameters are set

incorrectly.

Check the settings of the motor

configuration parameters in group 99.

The drive is not dimensioned

correctly.

Check that the drive is sized correctly for

the motor.

A6A5 No motor data Parameters in group 99 have

not been set.

Check that all the required parameters in

group 99 have been set.

Note: It is normal for this warning to

appear during the start-up and continue

until the motor data is entered.

A6A6 Voltage category

unselected

The voltage category has not

been defined.

Set voltage category in parameter 95.01

Supply voltage.

A6B0 User lock is open The user lock is open, ie. user

lock configuration parameters

96.100…96.102 are visible.

Close the user lock by entering an invalid

pass code in parameter 96.02

Pass

code. See section User lock (page 100).

A6B1

User pass code not

confirmed

A new user pass code has

been entered in parameter

96.100but not confirmed in

96.101.

Confirm the new pass code by entering

the same code in 96.101. To cancel,

close the user lock without confirming the

new code. See section User lock (page

100).

A6E5 AI parametrization The current/voltage hardware

setting of an analog input does

not correspond to parameter

settings.

Check the event log for an auxiliary code.

The code identifies the analog input

whose settings are in conflict.

Adjust parameter 12.15/12.25.

Note: Control board reboot (either by

cycling the power or through parameter

96.08 Control board boot) is required to

validate any changes in the hardware

settings.

A6E6 ULC configuration User load curve configuration

error.

Check the auxiliary code. See actions for

each code below.

0000 Speed points inconsistent. Check that each speed point (parameters

37.11…37.15) has a higher value than

the previous point.

0001 Frequency points inconsistent. Check that each frequency point

(37.16…37.20) has a higher value than

the previous point.

0002 Underload point above

overload point.

Check that each overload point

(37.31…37.35) has a higher value than

the corresponding underload point

(37.21…37.25).

0003 Overload point below

underload point.

A783 Motor overload Motor current is too high. Check the motor, and the machinery

coupled to motor, for overload.

Adjust the parameters used for the motor

overload function (35.51…35.53) and

35.55…35.56.

Code

(hex)

Warning / Aux. code Cause What to do

ACS180 FW.book Page 337 Tuesday, March 9, 2021 2:25 PM

Loading...

Loading...