Planning the electrical installation

63

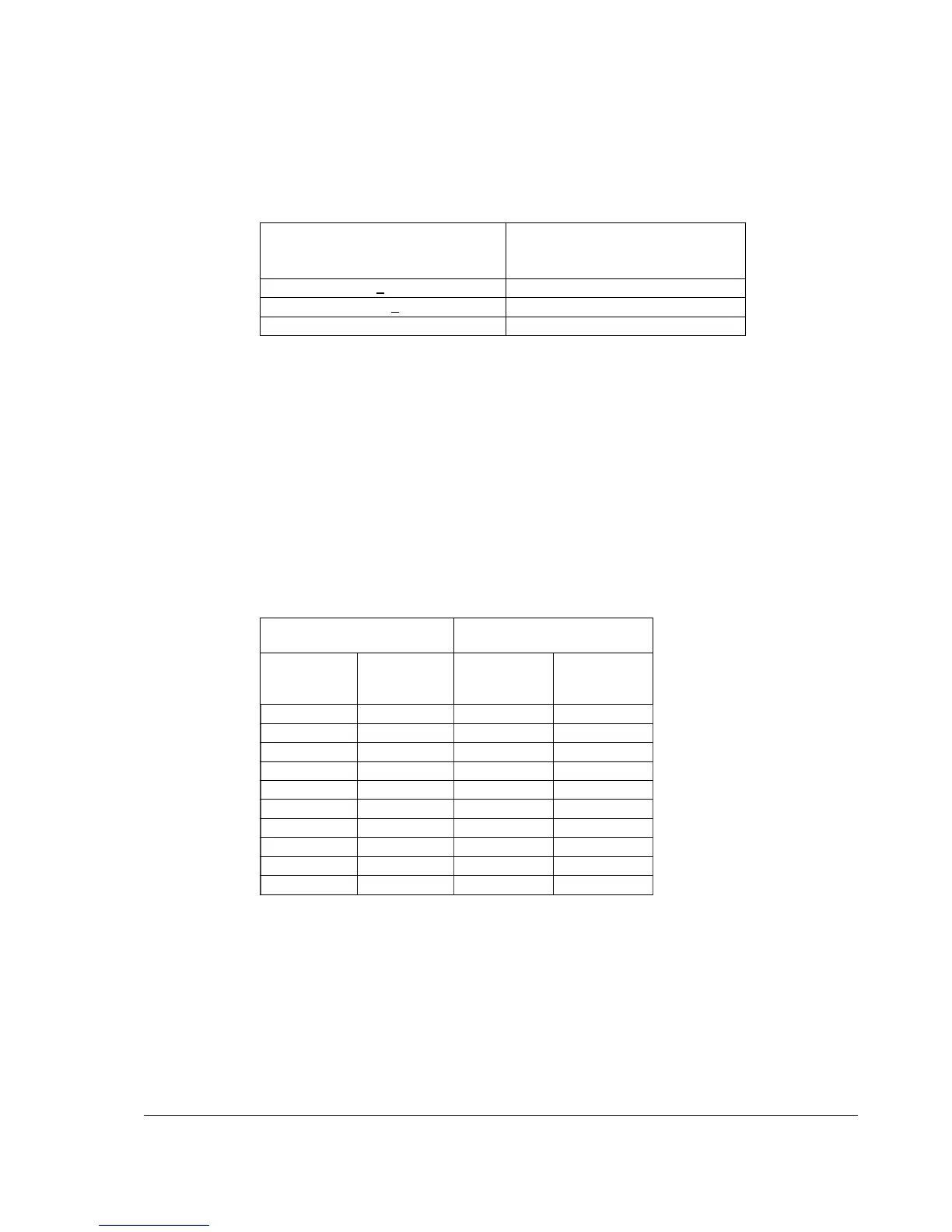

A four-conductor system is allowed for input cabling, but shielded symmetrical cable

is recommended. To operate as a protective conductor, the shield conductivity

requirements according to IEC 60439-1 are shown below when the protective

conductor is made of the same metal as the phase conductors:

Compared to a four-conductor system, the use of symmetrical shielded cable

reduces electromagnetic emission of the whole drive system as well as the stress on

motor insulation, bearing currents and wear.

Keep the motor cable and its PE pigtail (twisted shield) as short as possible to

reduce high-frequency electromagnetic emissions.

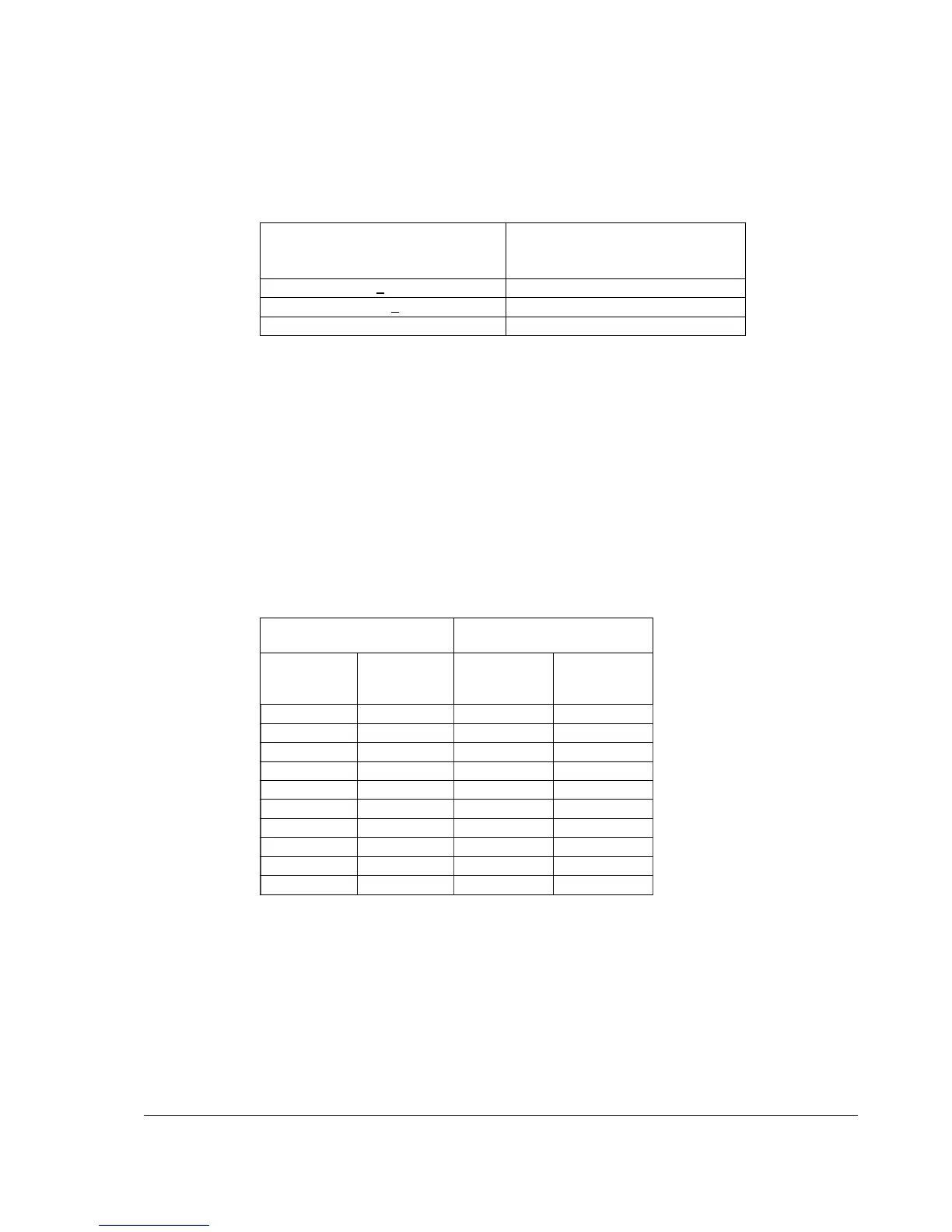

Typical power cable sizes

The table below gives copper and aluminium cable types for different load currents.

Cable sizing is based on max. 9 cables laid on a cable ladder side by side, three

ladder type trays one on top of the other, ambient temperature 30 °C, PVC

insulation, surface temperature 70 °C (EN 60204-1 and IEC 60364-5-52/2001). For

other conditions, dimension the cables according to local safety regulations,

appropriate input voltage and the load current of the drive.

Cross-sectional area of the phase

conductors

S (mm

2

)

Minimum cross-sectional area of the

corresponding protective conductor

S

p

(mm

2

)

S <

16 S

16 < S < 35 16

35 < S S/2

Copper cables with

concentric copper shield

Aluminium cables with

concentric copper shield

Max. load

current

A

Cable type

mm

2

Max. load

current

A

Cable type

mm

2

274 2 × (3×70) 302 2 × (3×120)

334 2 × (3×95) 348 2 × (3×150)

386 2 × (3×120) 398 2 × (3×185)

446 2 × (3×150) 470 2 × (3×240)

510 2 × (3x185) 522 3 × (3×150)

602 2 × (3×240) 597 3 × (3×185)

579 3 × (3×120) 705 3 × (3×240)

669 3 × (3×150)

765 3 × (3×185)

903 3 × (3×240)

3BFA 01051905 C

Loading...

Loading...