2.6.9 Programmable stop functions

Stopping functions

There are different methods to stop the robot, in addition to manually initiated

stops.

• Stop with system input signals

• Stop with RAPID instructions

• Other stops

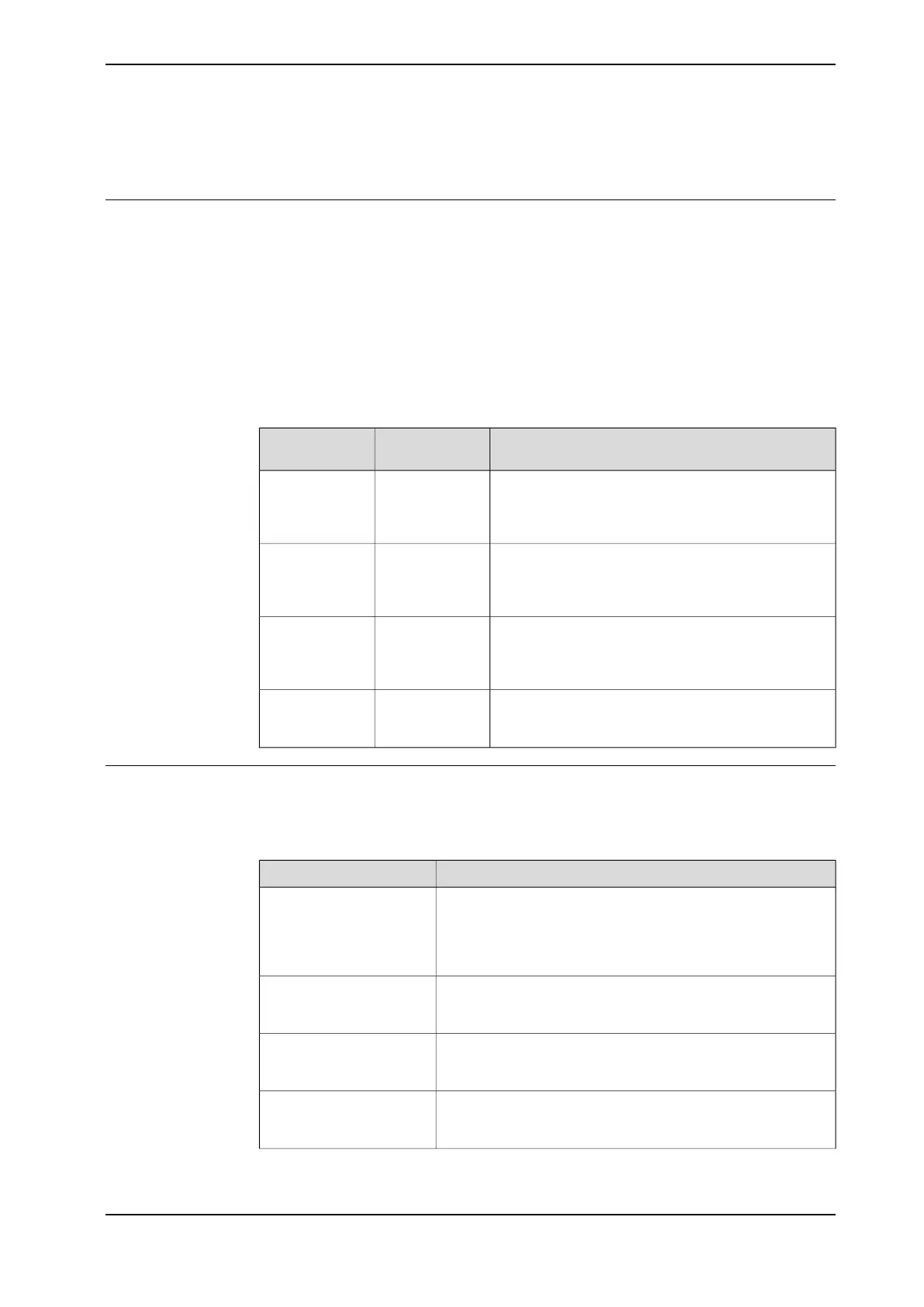

Stop category configuration

The stop category can be configured, see Technical reference manual - System

parameters.

DescriptionSystem paramet-

er Function

Safety inputs

SoftAS can be used to configure the protective stop

in automatic mode either as stop category 0 or cat-

egory 1. The default configuration is TRUE (stop cat-

egory 1).

SoftASAutomatic Stop

SoftGS can be used to configure the protective stop

in automatic and manual mode, either as stop category

0 or category 1. The default configuration is TRUE

(stop category 1).

SoftGSGeneral Stop

SoftSS can be used to configure the protective stop

in automatic and manual mode, either as stop category

0 or category 1. The default configuration is TRUE

(stop category 1).

SoftSSSuperior Stop

SoftES is used to configure the emergency stop in

automatic and manual mode. The default configuration

is FALSE (stop category 0).

SoftESEmergency Stop

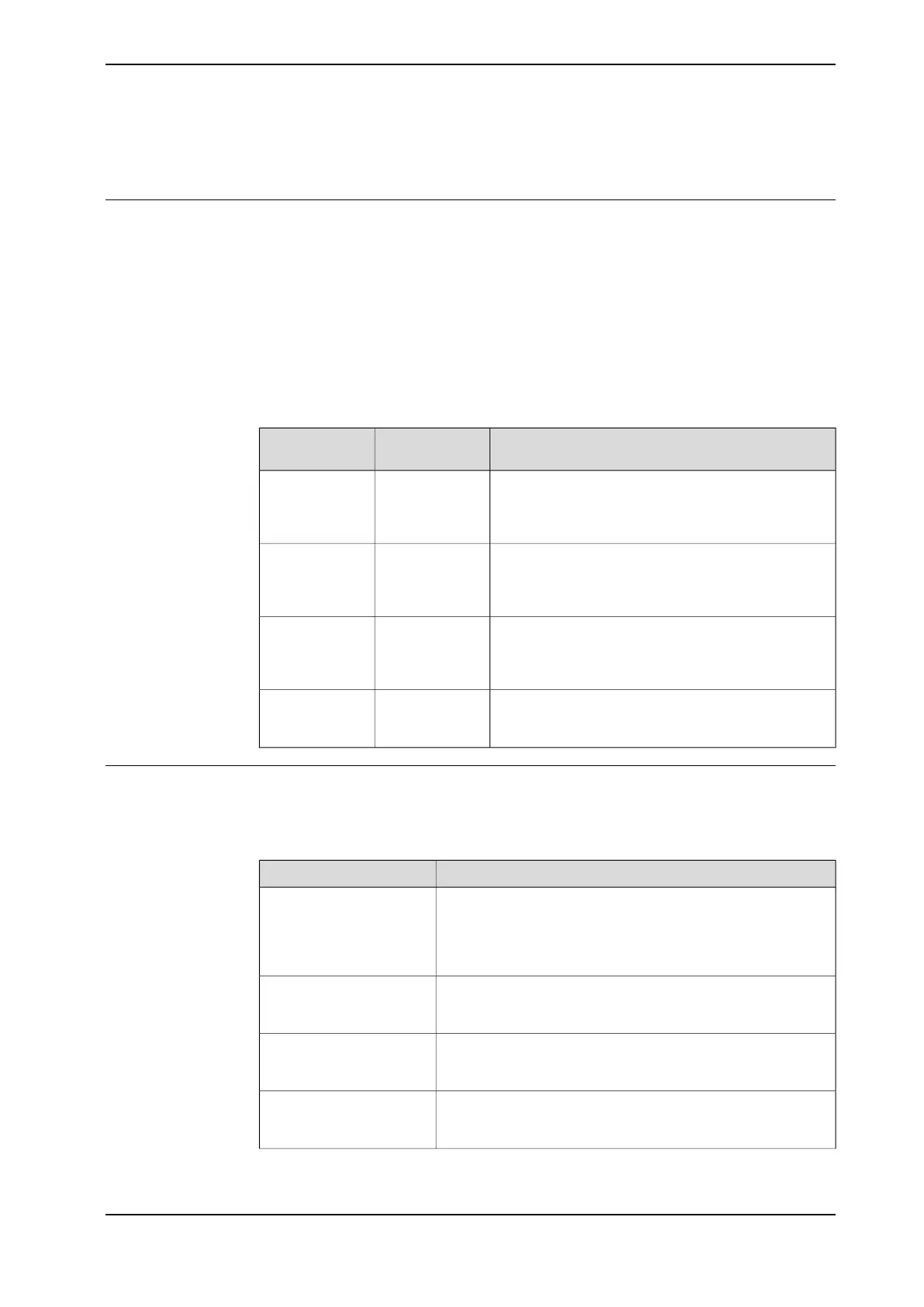

Stop with system input signals

In the control system, it is possible to define system input signals to be set/reset

through different interactions, for example, through networks, I/O blocks, RobAPI,

etc. See Application manual - Controller software IRC5.

DescriptionPre-defined system input

The RAPID program execution is stopped, and the manipulator

is stopped on path with no deviation. The RAPID program

cannot be started when this system input signal is high. This

stop is similar to a normal program stop using stop button on

the FlexPendant.

Stop

This is a faster stop of the manipulator than Stop. This stop is

more stressing for the mechanics than normal stop, therefore

there might be a minor deviation on path.

SoftStop

This is a faster stop of the manipulator than Stop and SoftStop.

This stop is more stressing for the mechanics than normal stop

or SoftStop, therefore there might be a deviation on path.

QuickStop

Stops the RAPID program when the complete program is ex-

ecuted, that means when the last instruction in the main routine

has been completed.

Stop at End of Cycle

Continues on next page

Product manual - IRC5 Compact 85

3HAC047138-001 Revision: G

© Copyright 2009-2017 ABB. All rights reserved.

2 Installation and commissioning

2.6.9 Programmable stop functions

Loading...

Loading...