Preface

MicroLogix 1000 Programmable Controllers User Manual

1–16

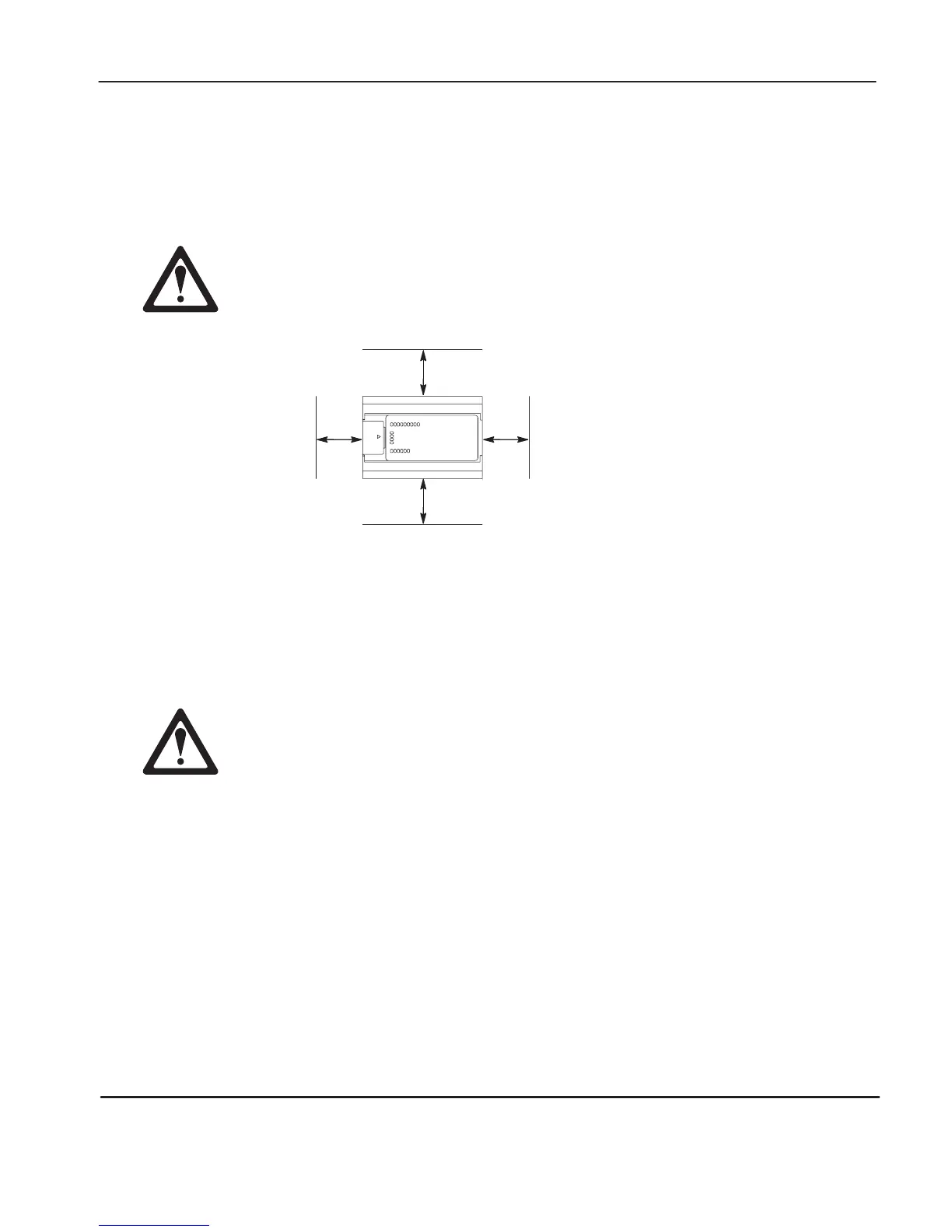

Controller Spacing

The following figure shows the recommended minimum spacing for the controller.

(Refer to appendix A for controller dimensions.)

Explosion Hazard — For Class I, Division 2 applications, this product must be

installed in an enclosure. All cables connected to the product must remain in

the enclosur

e or be pr

otected by conduit or other means.

20142

B

A

A. Greater than or equal to 50.8 mm (2 in.).

B. Greater than or equal to 50.8 mm (2 in.).

B

A

Top

Bottom

SideSide

Mounting the Controller

This

equipment is suitable for Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only, when product or packaging is marked.

Explosion Hazard:

• Substitution of components may impair suitability for Class I, Division 2.

•

Be car

eful of metal chips when drilling mounting holes for your controller.

Drilled fragments that fall into the controller could cause damage. Do not

drill holes above a mounted controller if the protective wrap is removed.

The controller should be mounted horizontally within an enclosure, using a DIN rail

or mounting screws.

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Loading...

Loading...