Application Example Programs

E–21

Bottle Line Example

The following application example illustrates how the controller high-speed counter

is configured for an Up/down counter. For a detailed explanation of:

• XIC, OTL, OTU and OTE instructions, see chapter 6.

• GRT, LES, and GEQ instruction, see chapter 7.

• HSC and HSL instructions, see chapter 12.

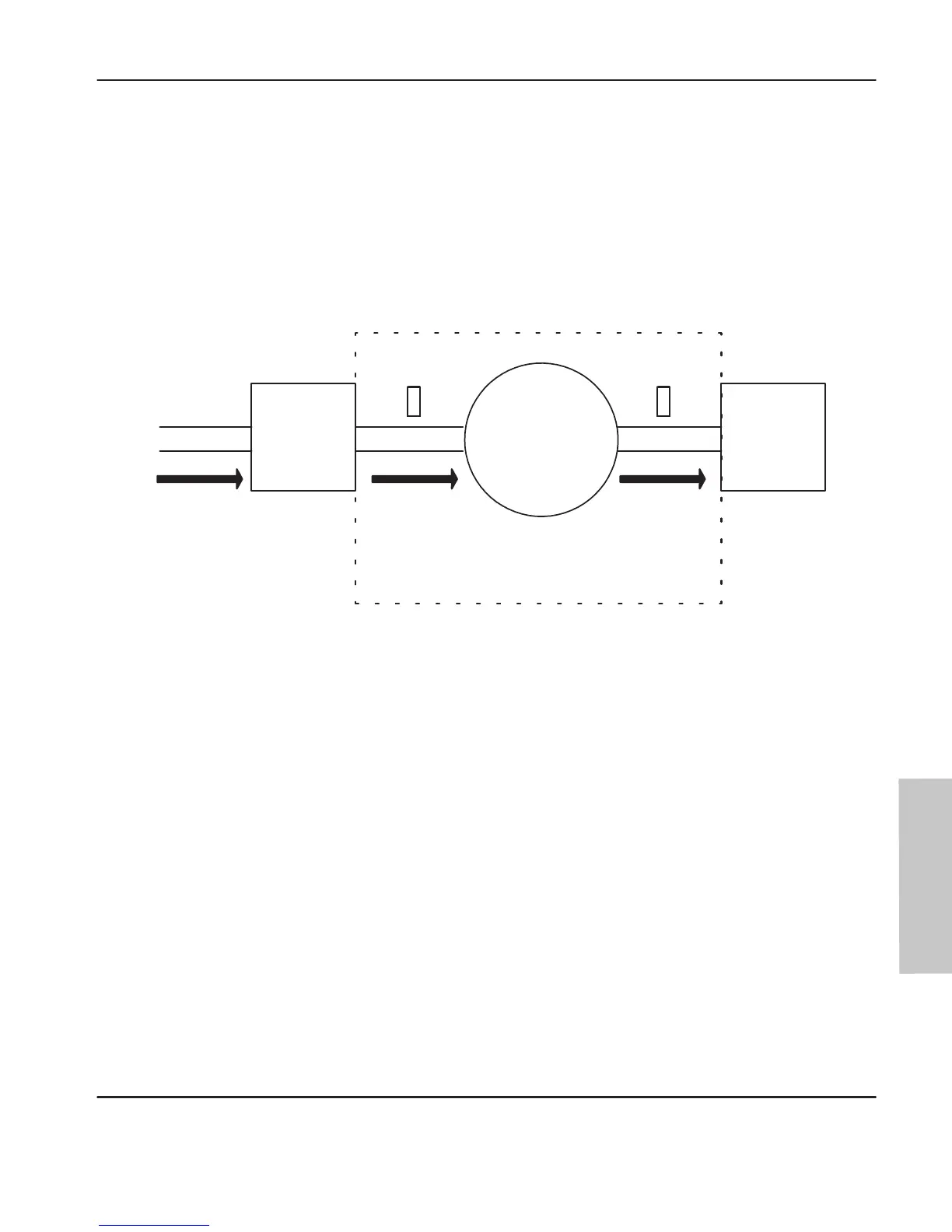

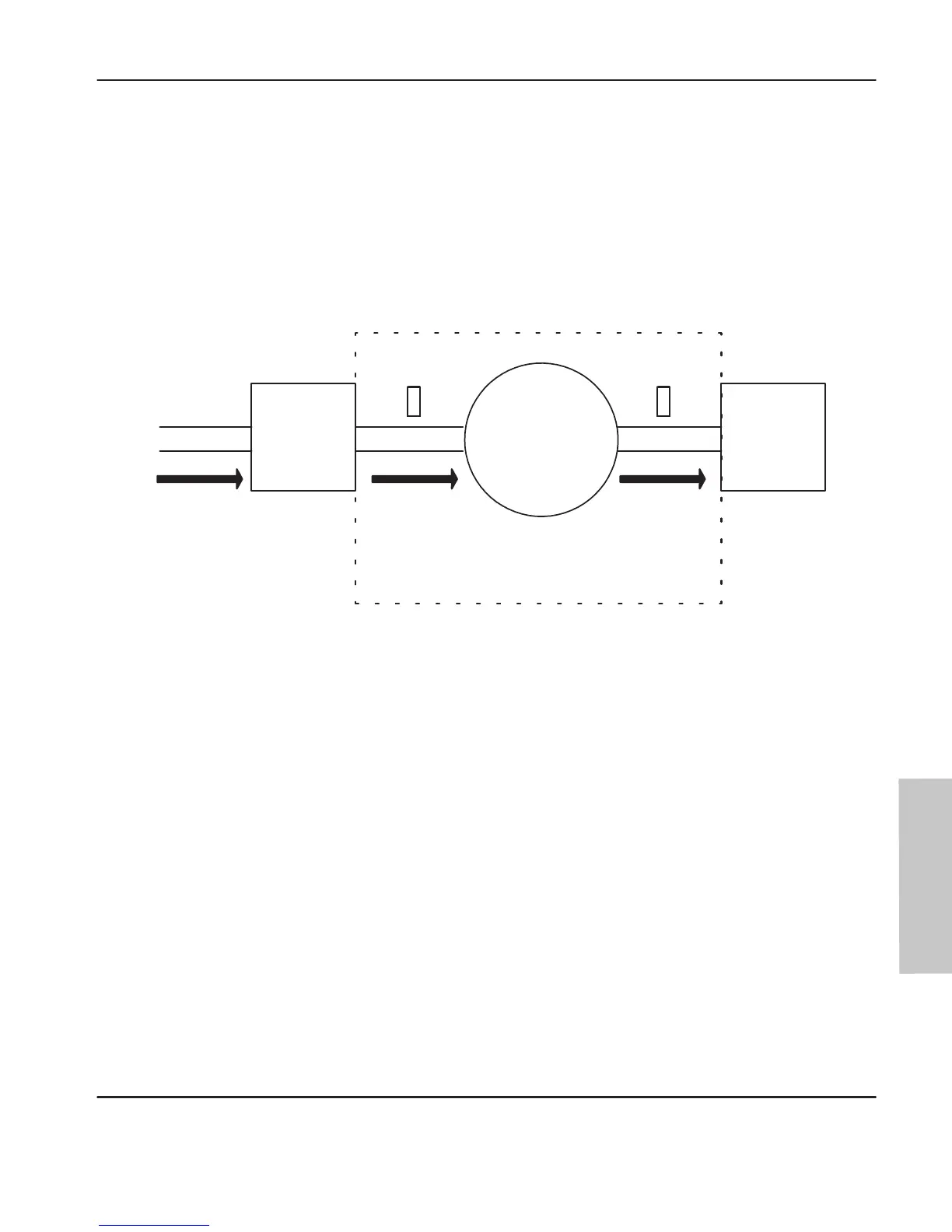

Stop Fill O:0/0

Slow Fill O:0/1

Sensor IN I:0/0

This section is controlled separately from the two

machines.

Sensor OUT I:0/1

Slow Pack O:0/2

Conveyor ConveyorConveyor

Bottle Fill and

Cap Machine

Packing Machine

Holding Area

Bottle Line Operation Overview

The controller on the conveyor

, within the specified area above, regulates the speeds

of the bottle fill and packing machines. Each machine is connected to a separate

controller that communicates with the conveyor controller. The following ladder

program is for the conveyor controller.

A conveyor feeds filled bottles past a proximity sensor (IN) to a holding area. The

proximity sensor is wired to the I/0 terminal (up count) of the conveyor controller.

The bottles are then sent on another conveyor past a proximity switch (OUT) to the

packing machine. This proximity switch is wired to the I/1 terminal (down count)

on the same controller.

Reference

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Loading...

Loading...