Publication 1785-UM012D-EN-P - July 2005

D-16 Instruction Set Quick Reference

Bit Modify and Move Instructions

Instruction Description

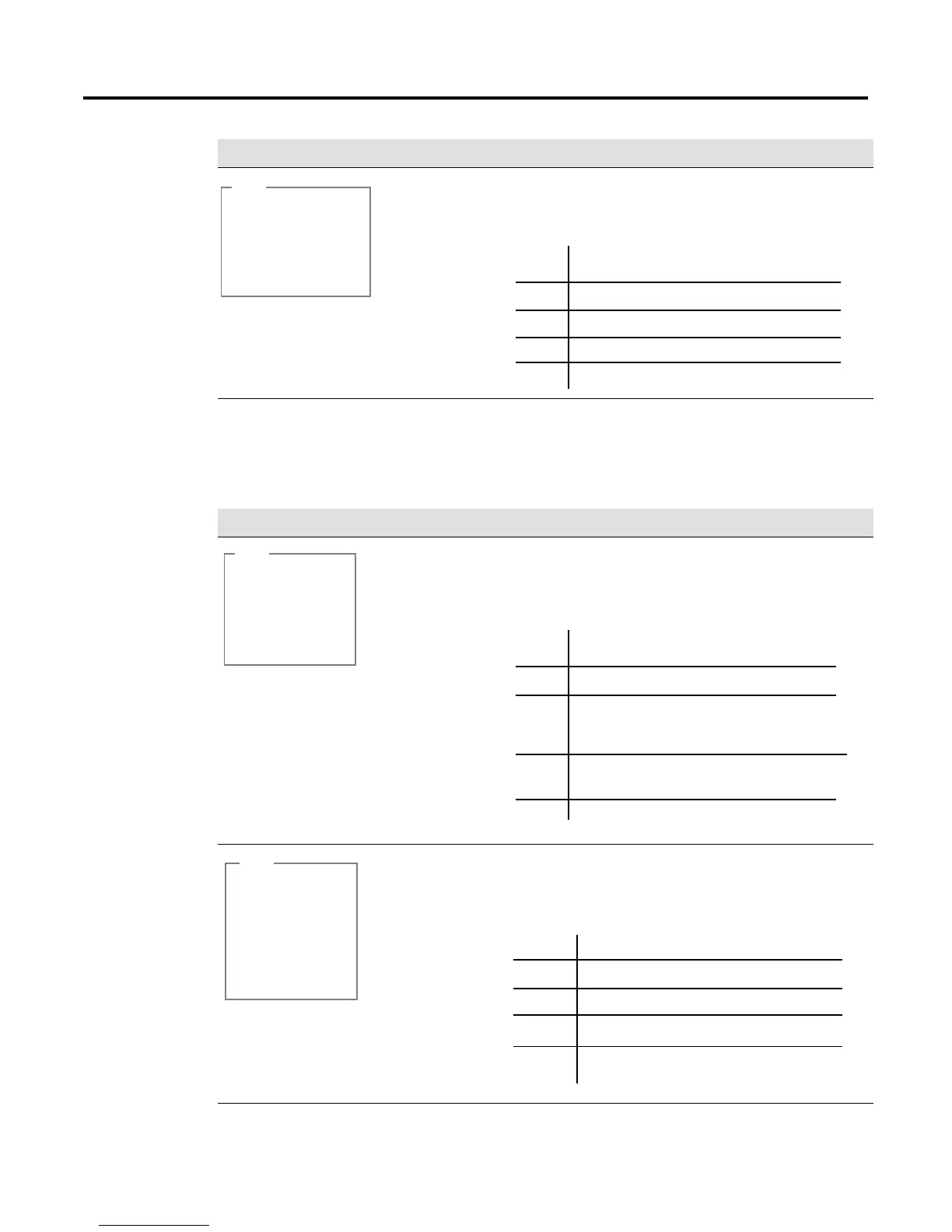

Convert to Radians

RAD

RAD

DEGREES TO RADIAN

Source

Dest

N7:9

0.785398

F8:10

45

When the input conditions are true, convert degrees (the

value in Source A) to radians and stores the result in the

Destination (Source times p/180).

Status

C

V

Z

S

Description

always resets

Bit

sets if overflow generated; otherwise resets

sets if result is zero; otherwise resets

sets if result is negative; otherwise resets

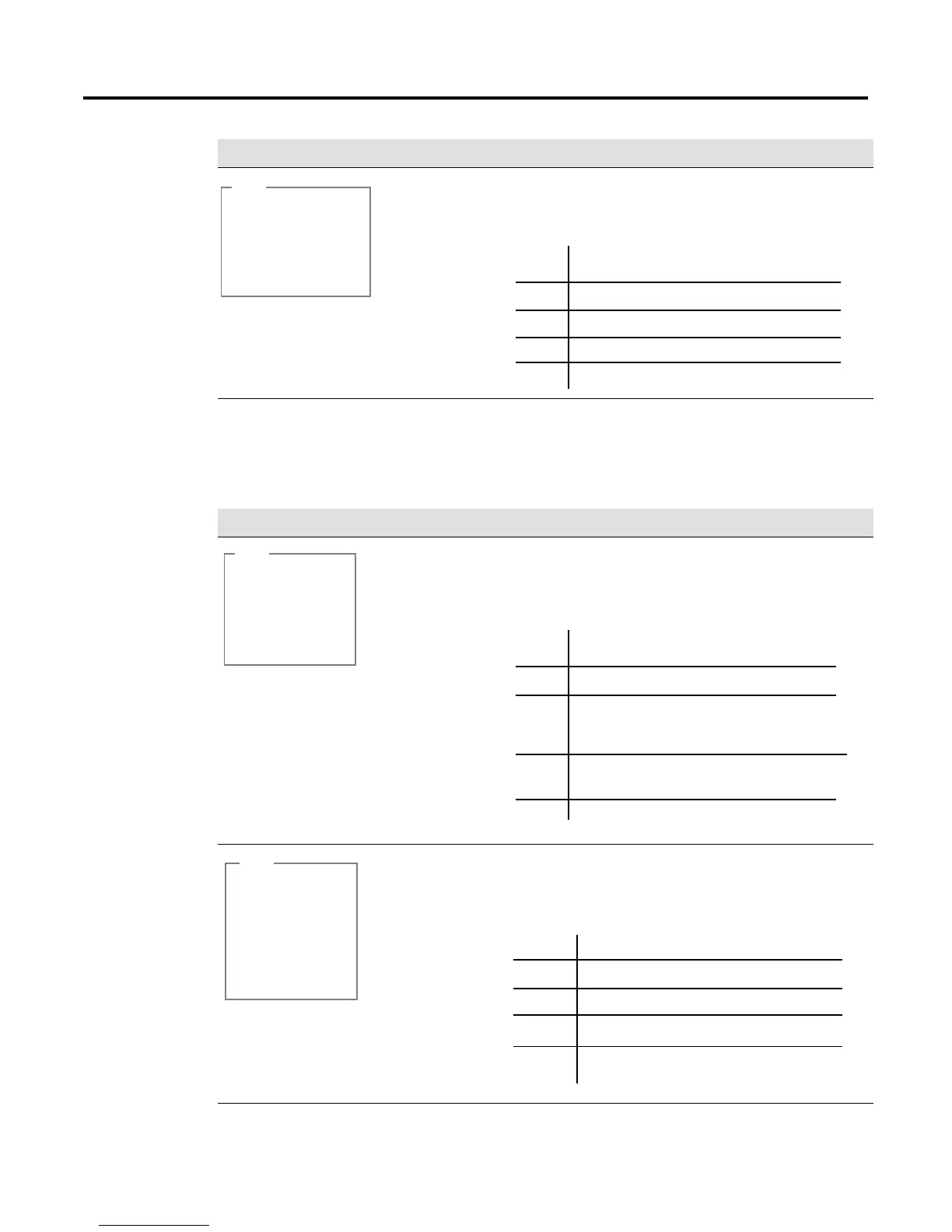

Instruction Description

Move

MOV

Masked Move

MVM

MOV

MOVE

Source N7:3

20

Dest F8:12

20.000000

When the input conditions are true, move a copy of the value i

Source (N7:3) to the Destination (F8:12), converting from one

data type to another This overwrites the original value in

the Destination.

Status

C

V

Z

S

Description

always resets

Bit

sets if overflow is generated during

sets if the destination value is zero;

sets if result MSB is set; otherwise resets

floating point-to-integer conversion;

otherwise resets

otherwise resets

MVM

MASKED MOVE

Source

Mask

Dest

D9:5

D9:12

478F

00FF

008F

D9:3

When the input conditions are true, the controller passes the

value in the Source (D9:3) through the Mask (D9:5) and stores

result in the Destination (D9:12). This overwrites the original

value in the Destination.

Status

C

V

Z

S

Description

always resets

Bit

always resets

sets if the result is zero; otherwise resets

sets if most significant bit of resulting value is set;

otherwise resets.

Loading...

Loading...