46

7113868.01 - en

INSTRUCTIONS FOR FITTERS

The authorised Technical Assistance Service can convert this boiler to natural gas (G. 20) or liquid gas (G. 30, G. 31).

18. GAS CONVERSION

TFDUJPO

r PQFOBIPUXBUFSUBQUIBUDBOQSPWJEFBáPXSBUFPGBUMFBTUMJUSFTBNJOVUFPSNBLFTVSFUIFSFJTNBYJNVNIFBU

EFNBOE

r DIFDLUIBUUIFCPJMFSGFFEJOHEZOBNJDQSFTTVSFBTNFBTVSFEBUUIFJOMFUHBTWBMWFQSFTTVSFUFTUQPJOU1B'JHVSFB

is correct (30 mbar for butane gas, 37 mbar for propane gas or 20 mbar for methaneHBT

r SFNPWFUIFNPEVMBUPSDPWFS

r BEKVTUUIFUVCFCSBTTTDSFXUPPCUBJOUIFQSFTTVSFTFUUJOHTTIPXOJOUBCMF

C2) Adjustment to reduced heat output:

r

EJTDPOOFDUUIFNPEVMBUPSGFFEJOHDBCMFBOEVOTDSFXUIFTDSFXUPSFBDIUIFQSFTTVSFTFUUJOHDPSSFTQPOEJOHUPSFEVDFE

IFBUPVUQVUTFFUBCMF

r SFDPOOFDUUIFDBCMF

r àUUIFNPEVMBUPSDPWFSBOETFBM

C3) Final checks

r BUUBDIUIFBEEJUJPOBMQMBUFTVQQMJFEXJUIUIFUSBOTGPSNFSTQFDJGZJOHUIFUZQFPGHBTBOEUIFDBMJCSBUJPOQFSGPSNFE

Carry out the following operations:

"SFQMBDFUIFNBJOCVSOFSOP[[MFT

B) change the modulator voltage

C) new max. and min. calibration of the pressure regulator.

A) Replace the burner injectors

r DBSFGVMMZQVMMUIFCVSOFSPGGJUTTFBU

r SFQMBDF UIFCVSOFSJOKFDUPST NBLJOH TVSFUP GVMMZ UJHIUFO

them to prevent gas leaks. Injector diameters are specied

in table

2.

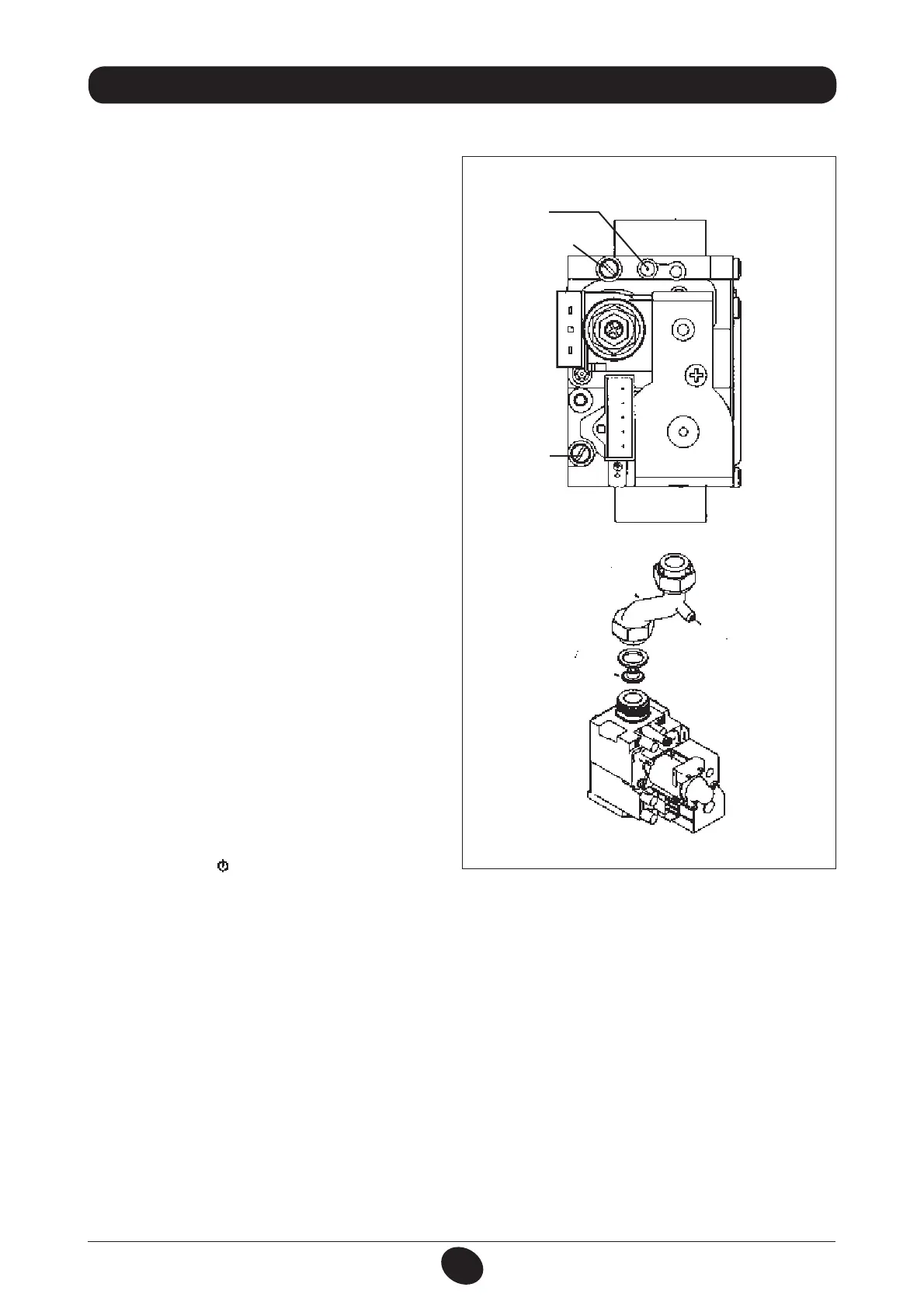

Replacing the diaphragm nozzle

GPSNPEFMTJBOE'J

r SFNPWFUIFHBTJOMFUIPTFPG'JHVSFC

r SFQMBDFUIFEJBQISBHNOP[[MFNPVOUFEPOUIFHBTWBMWF

r QVUCBDLUIFHBTJOMFUIPTF

B) Change the modulator voltage

r set parameter F02 according to the gas used, as descri-

bed in section

20.

C) Calibrate the pressur

e regulator

r DPOOFDUUIFQPTJUJWFQSFTTVSFUFTUQPJOUPGBEJGGFSFOUJBM

pressure gauge (possibly water-operated) to the gas valve

pressure test point (Pb) (Figure 12a). For models 240 i/Fi

use the pressure tap (3) in the gas inlet hose (gure 12b).

Connect, for sealed chamber models only, the negative

pressure test point of the manometer to a “T” tting in

order to join the boiler adjusting outlet, the gas valve

adjusting outlet (Pc) and the manometer. (The same

measurement can be made by connecting the pressure

gauge to the pressure test point (Pb) after removing the

GSPOUQBOFMPGUIFTFBMFEDIBNCFS

Measuring burner pressure using methods other than

those described could lead to incorrect results as the low

pressure created by the fan in the sealed chamber would

not be taken into account.

C1) Adjustment to nominal heat output:

r PQFOUIFHBTDPDL

r QSFTTUIF CVUUPO

(and set the boiler in winter mode

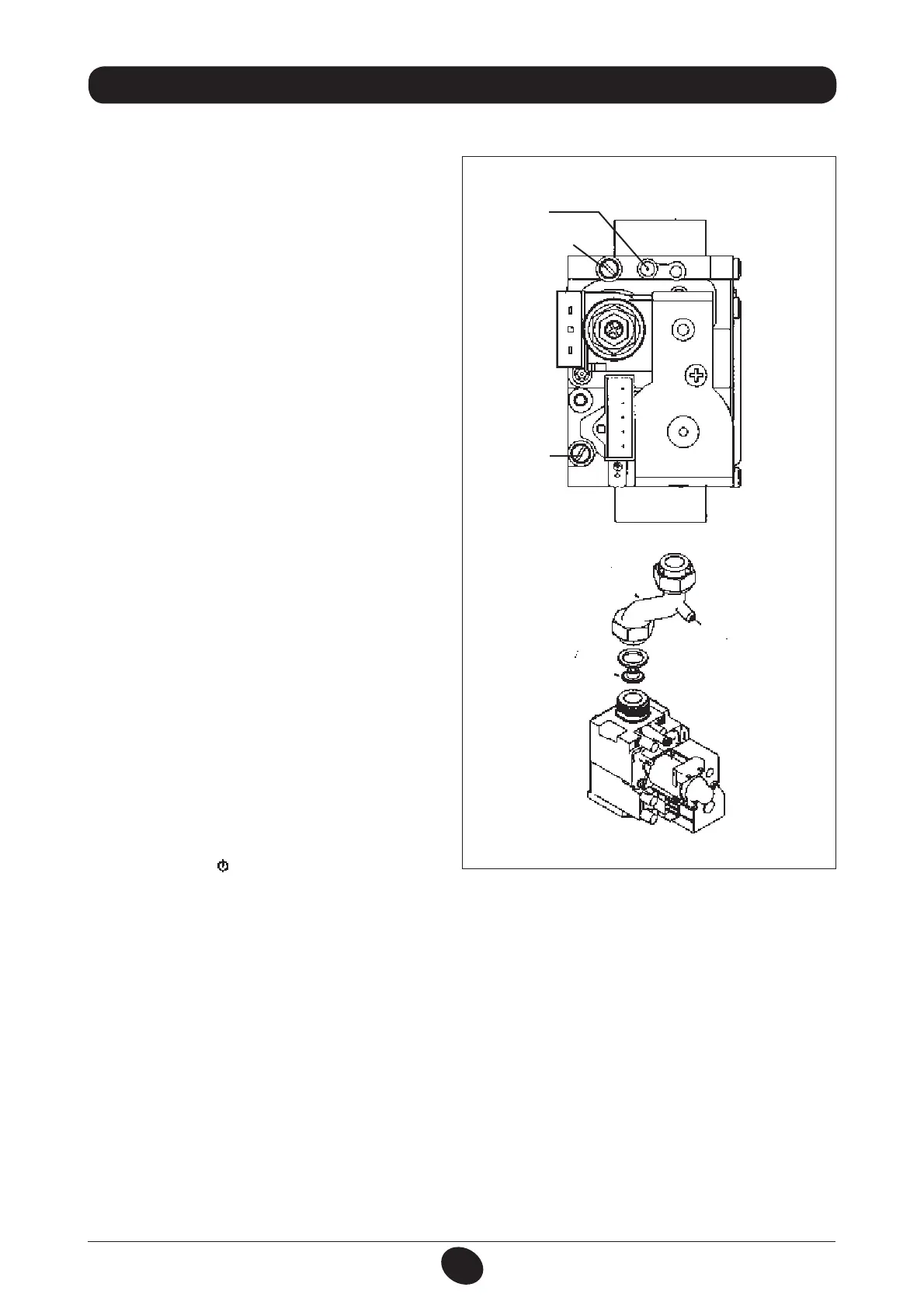

Valve SIT

mod. SIGMA 845

Figure 12a

9912221500

Pc

Pb

Pa

0206_0501

Figure 12b (models 240 i - 240 Fi)

Loading...

Loading...