52

7113868.01 - en

INSTRUCTIONS FOR FITTERS

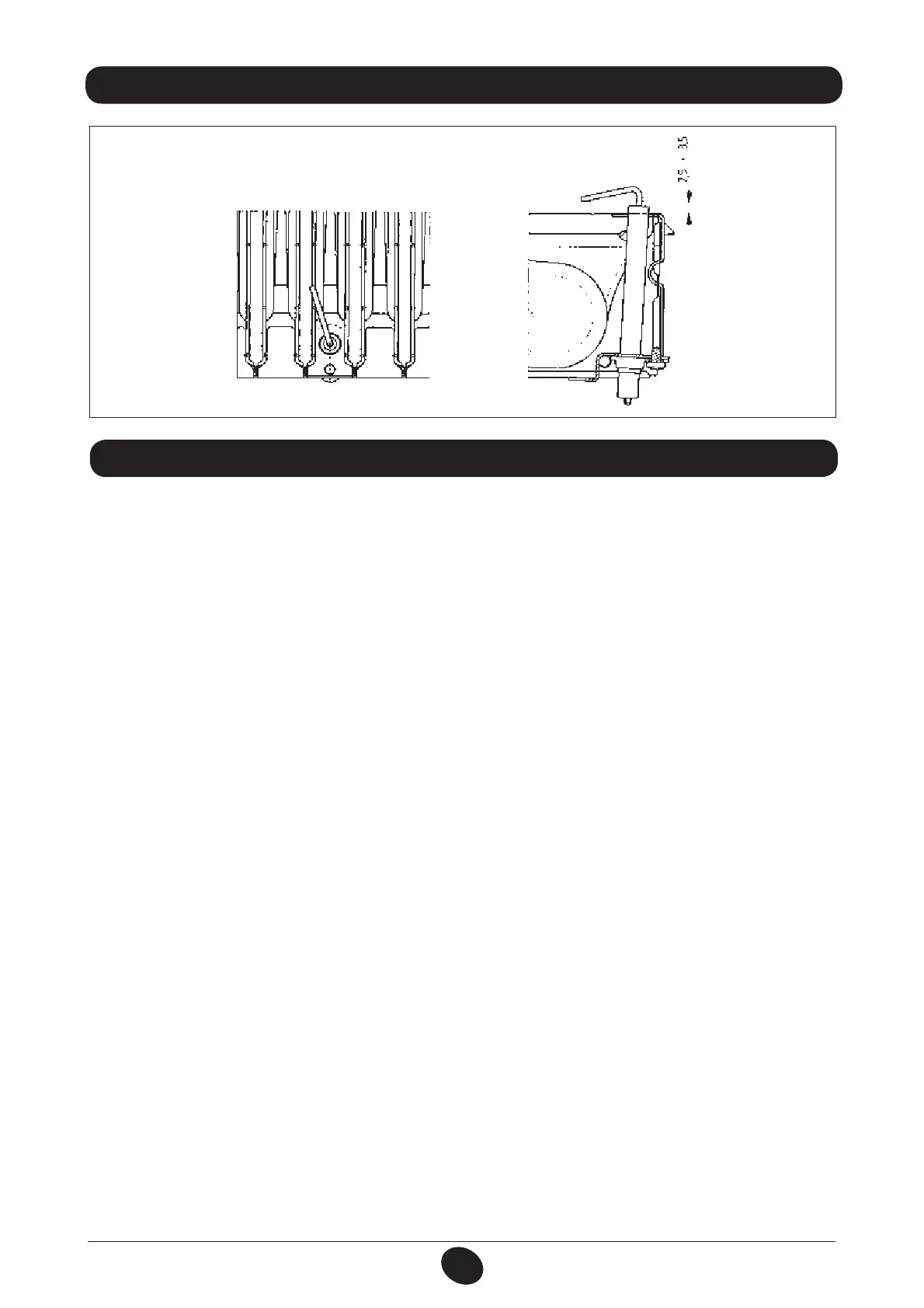

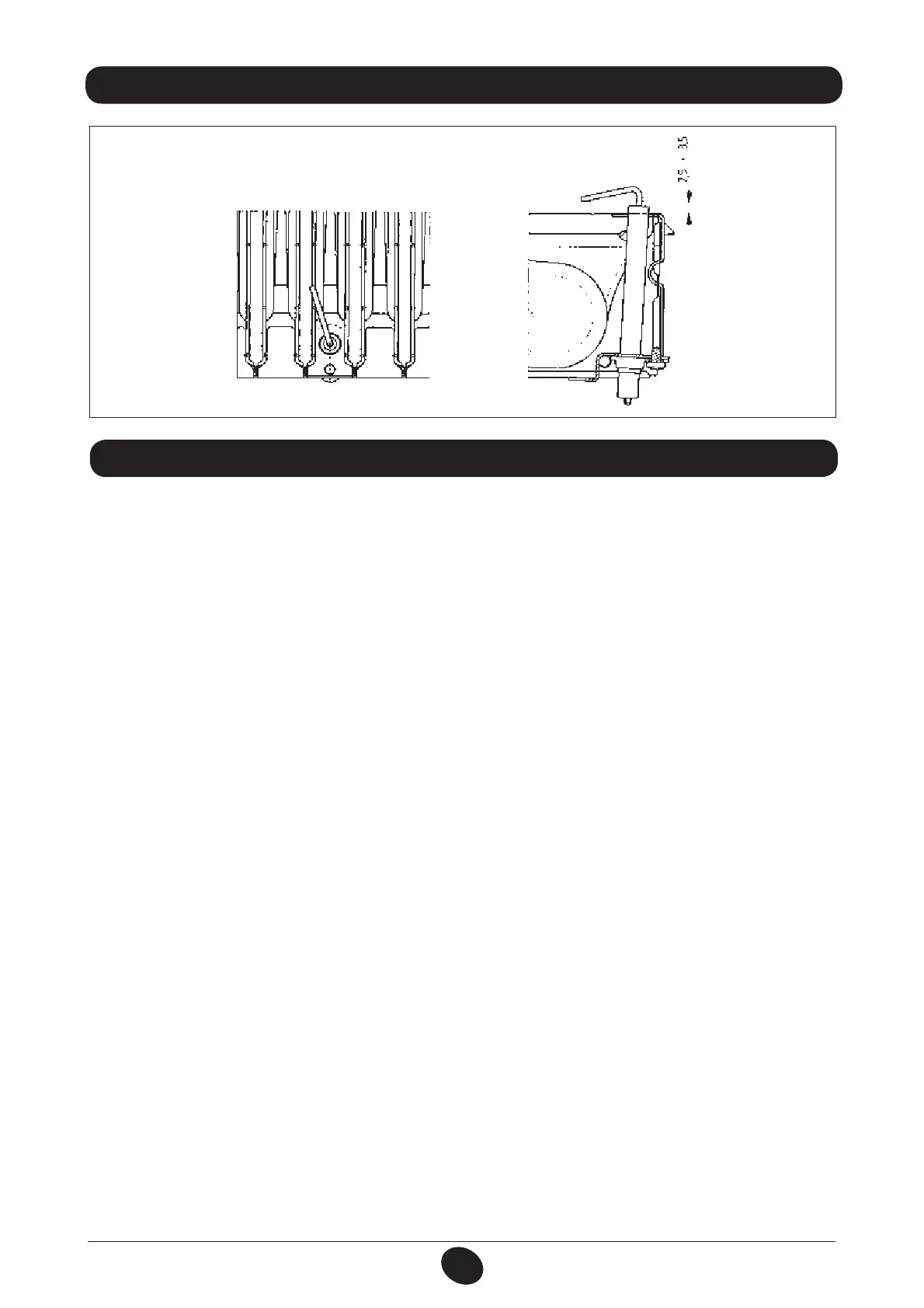

22. POSITIONING THE IGNITION AND FLAME-SENSING ELECTRODE

Figure 14

9912070100

To measure combustion performance and the toxicity of the products of combustion, the forced-ow boilers are tted with

two dedicated taps on the concentric connector.

One connection point is connected to the exhaust duct and is used to measure combustion efciency and the toxicity of

the products of combustion.

The other is connected to the air intake circuit and is used to check for the presence of any products of combustion circu-

lating in installations with co-axial ues.

The following parameters can be measured at the connection point on the ue gas circuit:

rUFNQFSBUVSFPGUIFQSPEVDUTPGDPNCVTUJPO

rDPODFOUSBUJPOPGPYZHFO0

2

) or, alternatively, carbon dioxide (CO

2

rDPODFOUSBUJPOPGDBSCPONPOPYJEF$0

The combustion air temperature must be measured at the connection point on the air intake circuit, inserting the measu-

rement probe to a depth of about 3 cm.

For natural draught boiler models, a hole must be made in the exhaust ue at a distance from the boiler equal to twice

the internal diameter of the ue.

The following parameters can be measured through this hole:

rUFNQFSBUVSFPGUIFQSPEVDUTPGDPNCVTUJPO

rDPODFOUSBUJPOPGPYZHFO0

2

) or, alternatively, carbon dioxide (CO

2

rDPODFOUSBUJPOPGDBSCPONPOPYJEF$0

The temperature of the combustion air must be measured close to the point where the air enters the boiler.

The hole, which must be made by the person in charge of the system during commissioning, must be sealed so as to

ensure that the exhaust duct is airtight during normal operation.

23. CHECKING COMBUSTION PARAMETERS

Loading...

Loading...