- 148 -vLP Engine G430(3.0L) Base Engine Service Procedure

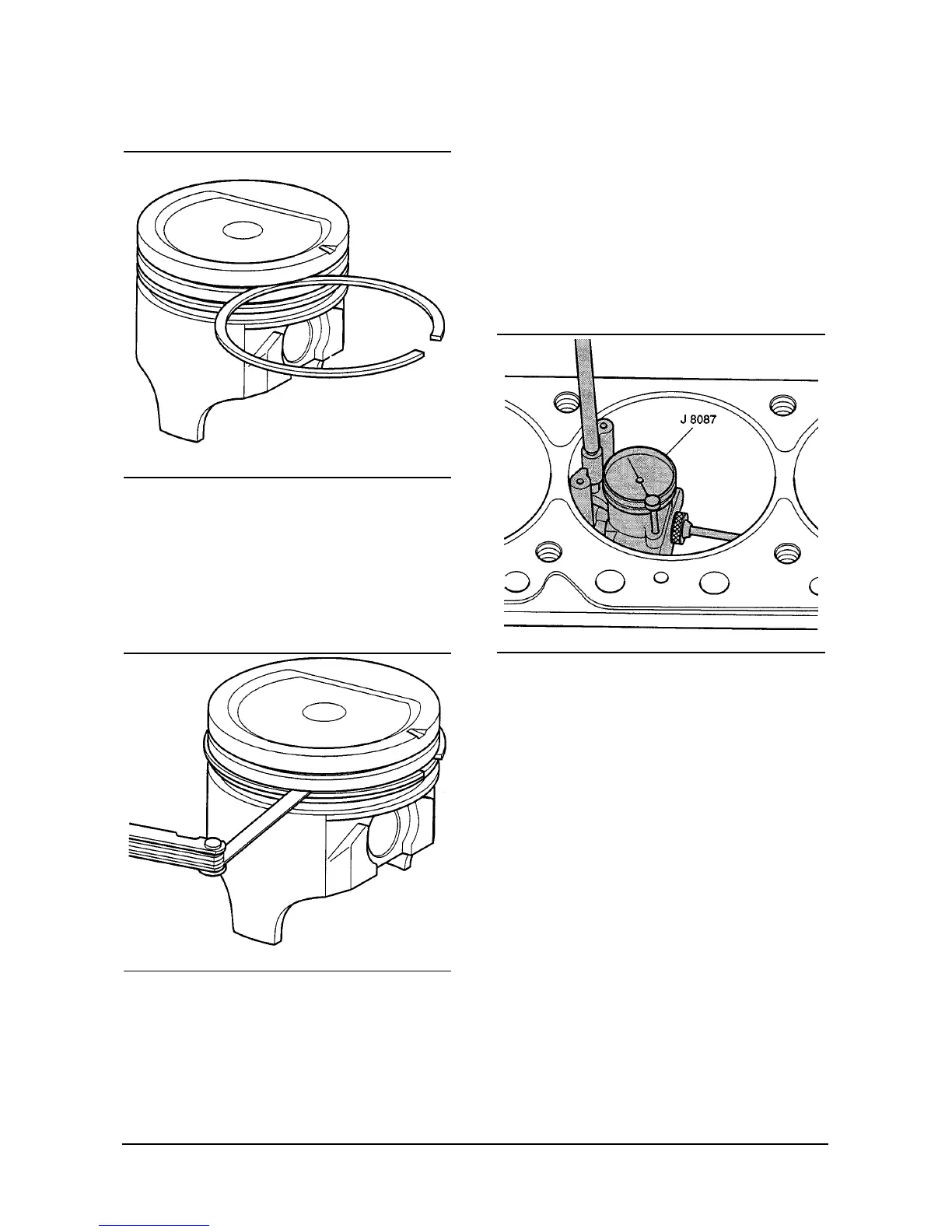

12. Measure the piston ring side clearance.

(1) Roll the piston ring entirely around its ring

groove on the piston.

(2) Dress the groove with a fine cut file if the ring

groove causes binding.

(3) Replace the piston ring if a distorted piston ring

causes binding.

(4) Use a feeler gauge in order to measure the

side clearance of the piston ring and groove.

(5) Try another piston ring if the side clearance is

too small.

Piston Selection

IMPORTANT: Measurements of all components

should be taken with the components at normal room

temperature.

For proper piston fit, the engine block cylinder bores

must not have excessive wear or taper.

A used piston and pin set may be reinstalled if, after

cleaning and inspection, they are within specifications.

1. Inspect the engine block cylinder bore. Refer to

Cylinder Block Clean and Inspect.

2. Inspect the piston and piston pin. Refer to Piston

and Connecting Rod Clean and Inspect.

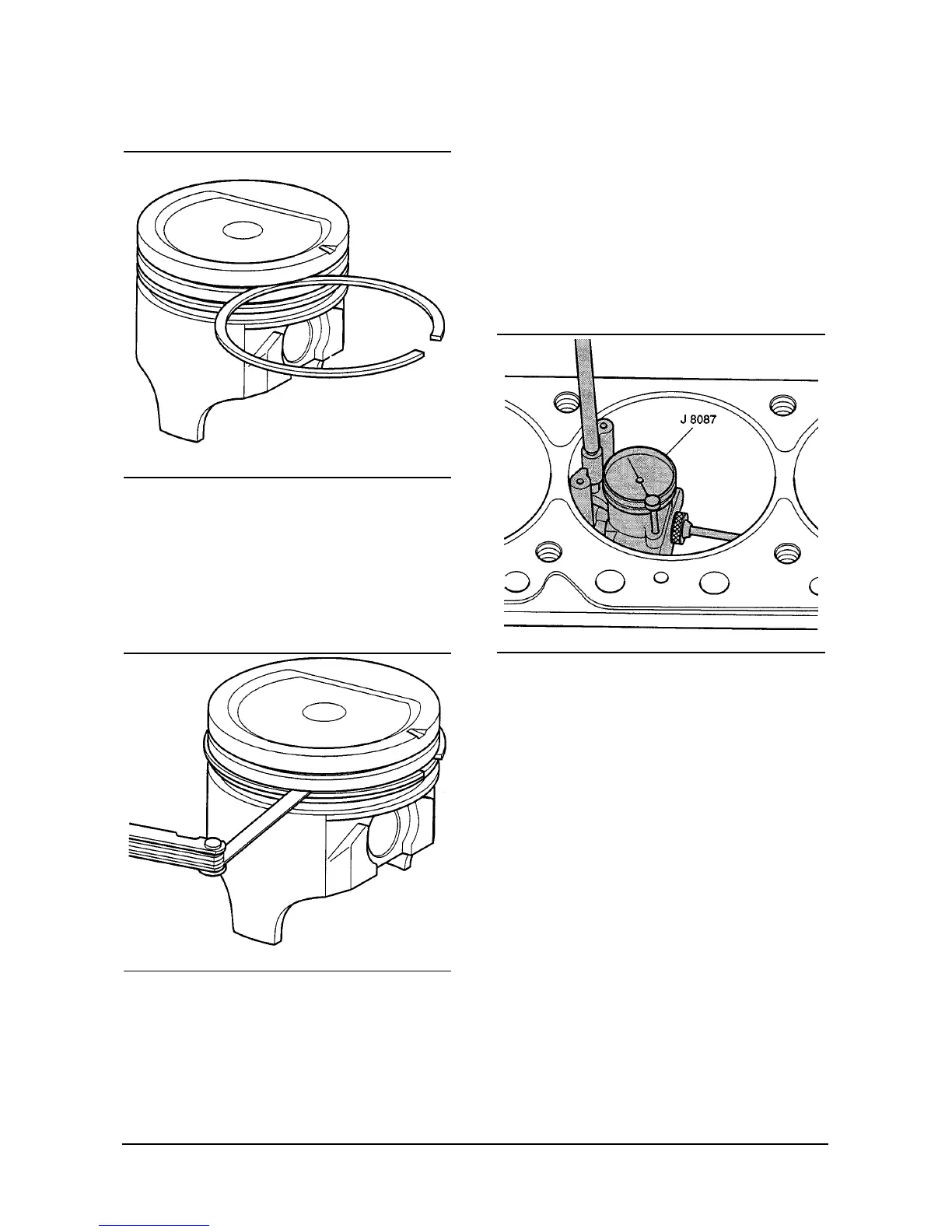

3. Use a boring gauge in order to measure the cylinder

bore diameter at a point of 66 mm (2.5 in) from the

top of the cylinder bore.

VE060-3L

VE071-3L

VE070-3L

Loading...

Loading...