- 83 -

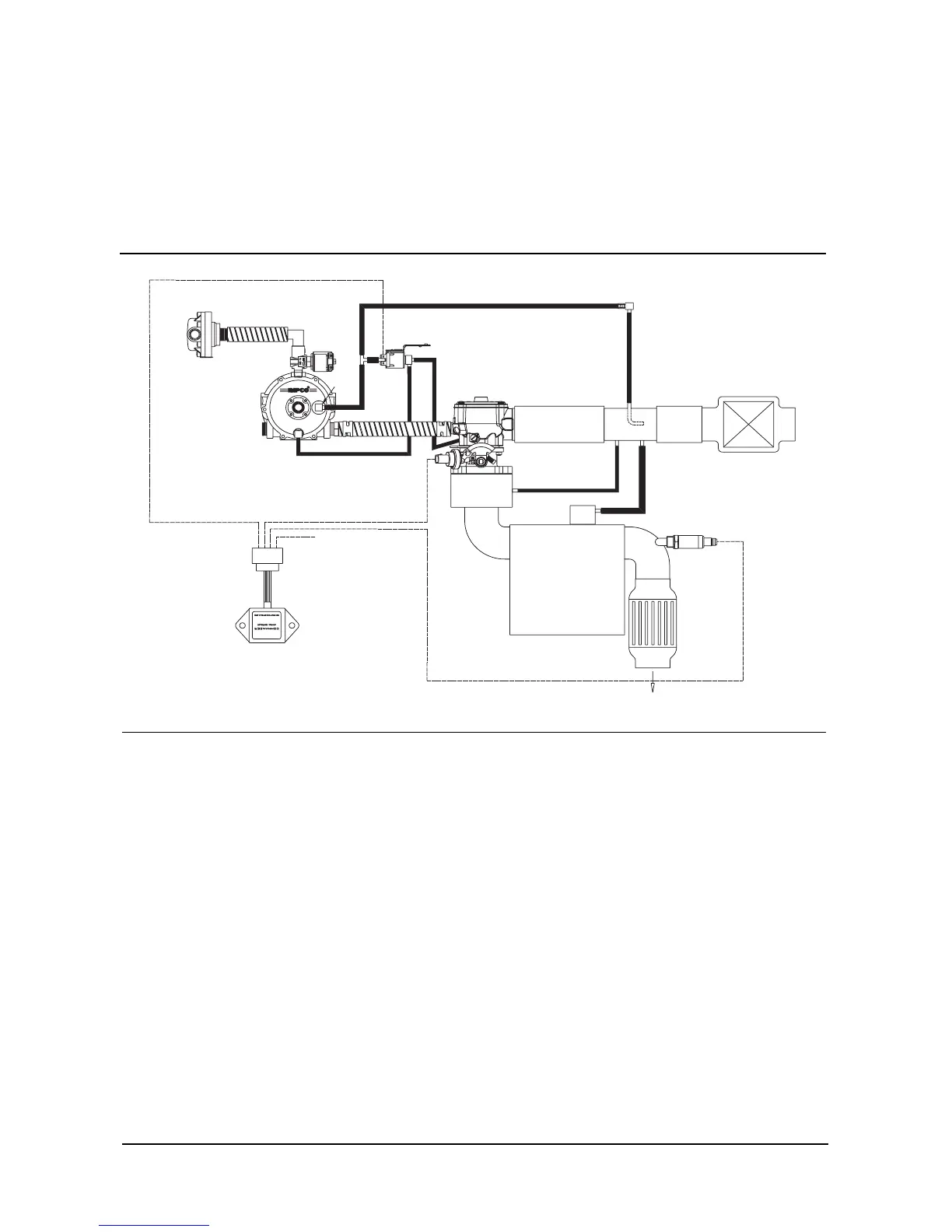

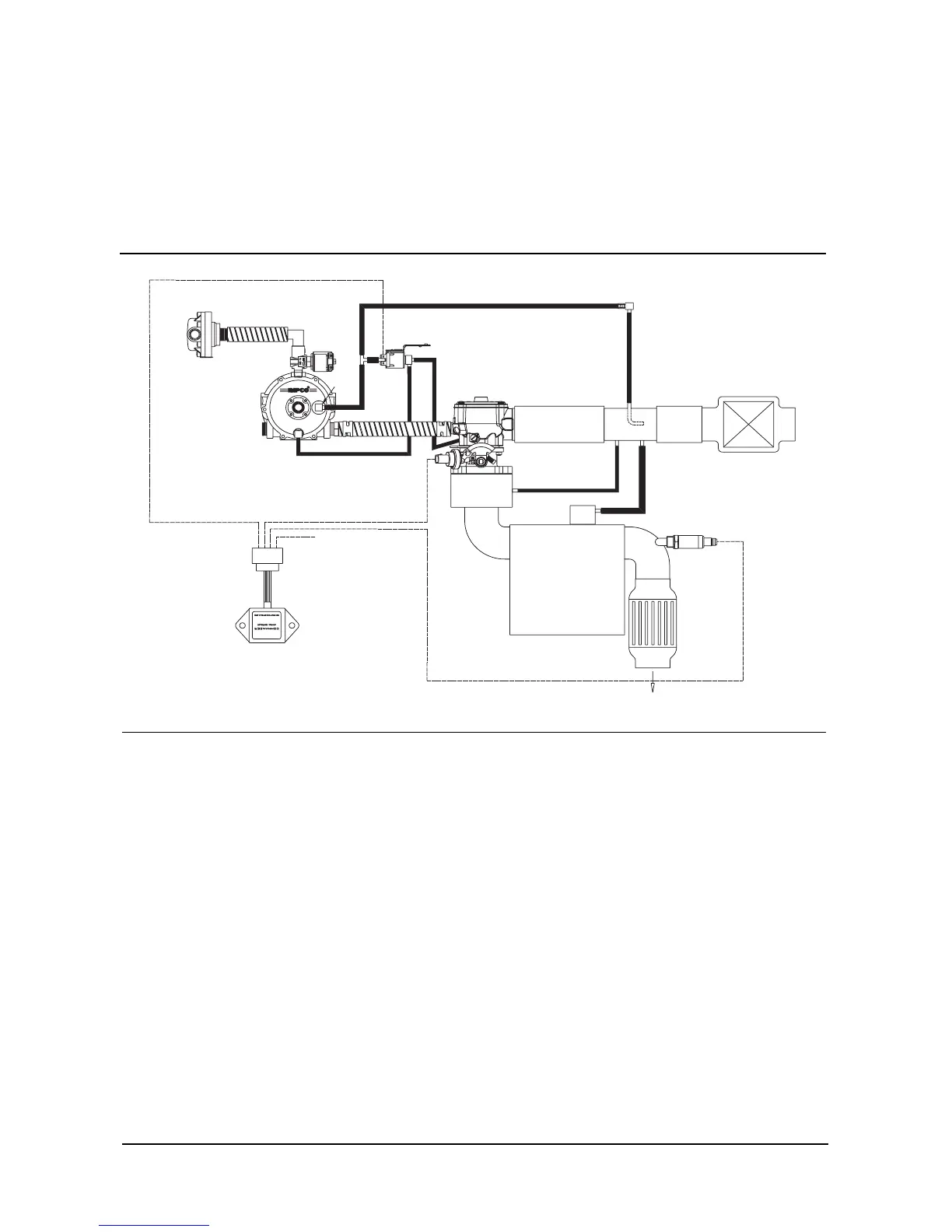

LP Engine G430(3.0L) LP Fuel System (Low Emission Version)

LP FUEL SYSTEM (LOW EMISSION VERSION)

General Description

System Overivew

CARB(Carlifornia Air Resource Board) emission

compliant G430 LP engine is different from

standard G430 LP engine. To reduce emission of

exhaust gas, closed loop carburetion system and

catalytic muffler are applied to emission compliant

G430 LP engine.

Catalytic muffler reduces the emission level in the

exhaust gas. In order to obtain maximum effect

from the catalyst, an accurate control of the air fuel

ratio is required. The engine controller uses an

exhaust gas oxygen sensor (EGO) in the exhaust

system to send information about exhaust gas

content to the controller. The controller then

calculates any corrections that may need to be

made to the air fuel ratio. The controller makes

these corrections to the air fuel ratio by manipulating

the inlet fuel pressure to the carburetor through the

fuel control valve (FCV). Reducing the fuel

pressure leans the air/fuel mixture. Increasing the

fuel pressure richens the air/fuel mixture.

The controller uses engine exhaust gas oxygen

sensors (EGO), engine speed (tachometer signal)

and manifold absolute pressure sensors (MAP), to

regulate the air/fuel mixtures, correcting for proper

air/fuel. The fuel control valve (FCV) meters air

valve vacuum (AVV) into the atmospheric reference

side of the secondary regulator diaphragm. The

atmospheric reference vent orifice allows for the

controlled depletion of the vacuum over the

diaphragm, this assists the dynamic response of

the diaphragm.

LP Fuel System (Low Emission Version)

Loading...

Loading...