- 24 -

LP Engine G430(3.0L) Maintenance

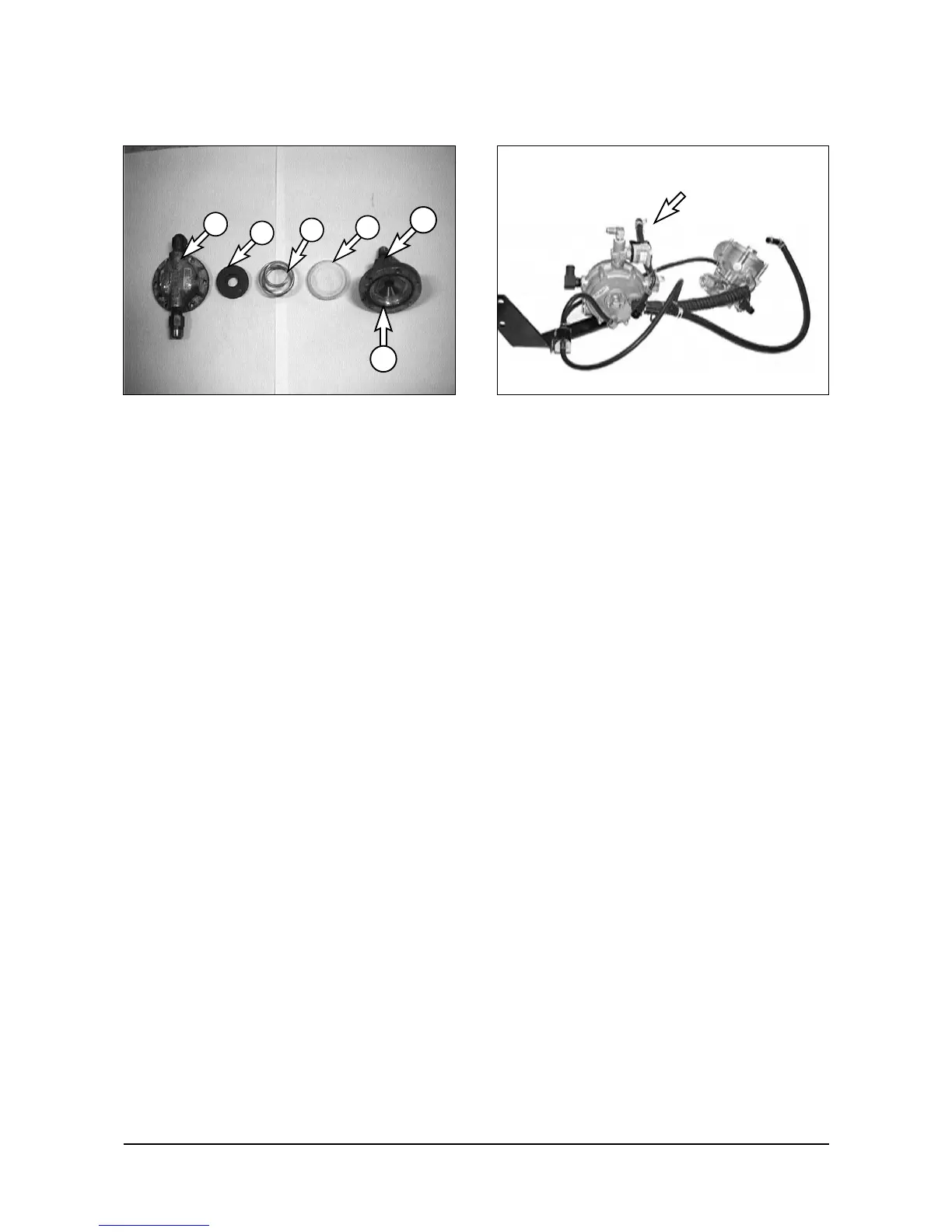

4. Remove cover (5), magnet (4), spring (3) and

filter element (2) from bottom cover (1).

5. Replace the filter element (2).

6. Check bottom cover O-ring seal (6) for damage,

Replace it if necessary.

7. Install the filter element (2), spring (3), magnet

(4) and cover (5) on bottom cover (1). Align the

scribe line on the covers.

8. Install the cover retaining screws. Tighten the

screws in a sequence opposite each other.

9. Open the fuel valve by slowly turning the valve

counterclockwise.

10. Crank the engine only enough to produce a

vacuum at the fuelock. Turn the ignition key

switch off.

11. Check the fuel lines and fittings for leaks with a

soap solution. Make repairs if necessary.

Test fuel lock (electric)

●

Start engine.

●

Locate electrical connector for fuel lock.

●

Disconnect electrical connector.

●

Engine will run out of fuel and stop in a short period

of time. (The length of time increases with any

increase in distance between the fuel lock and the

pressure regulator).

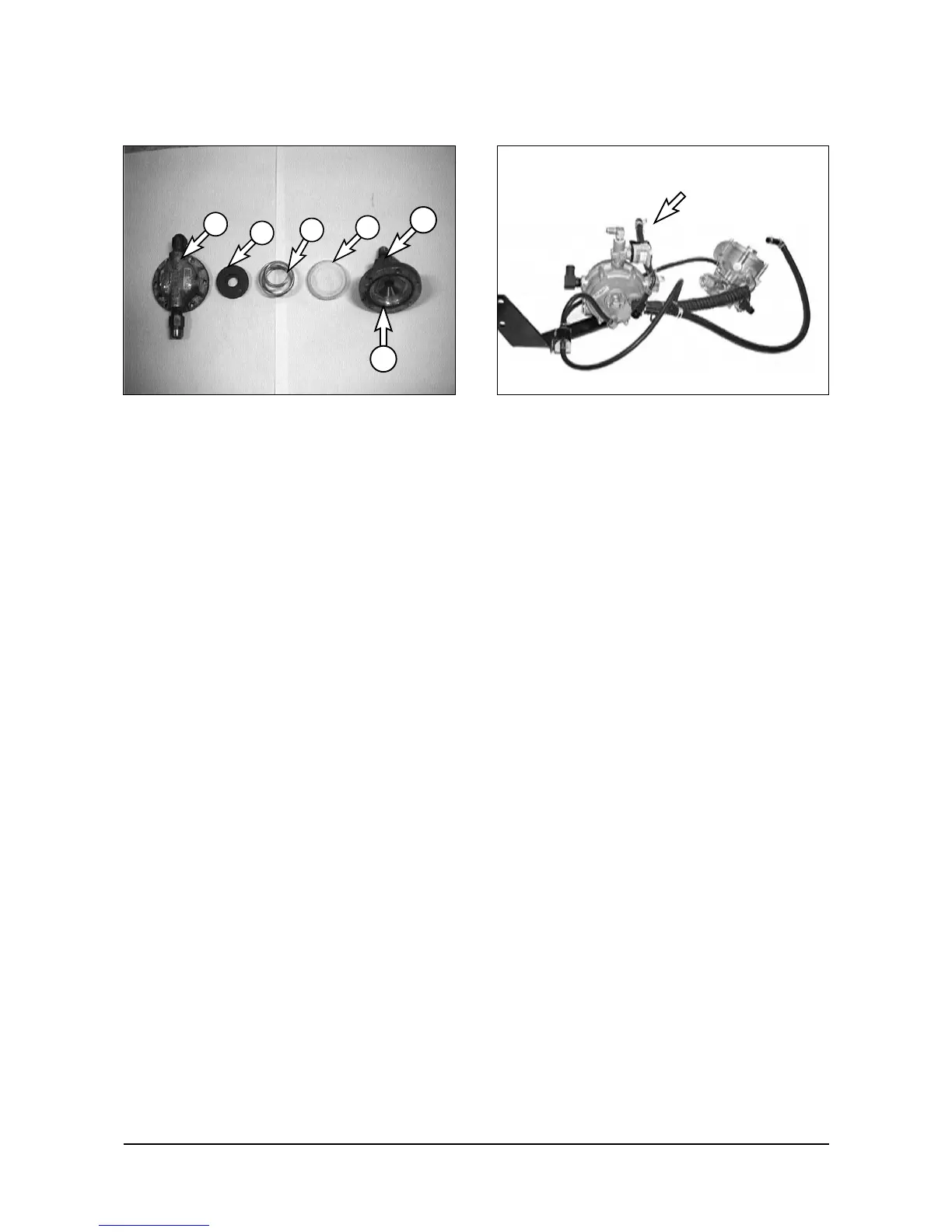

Inspect pressure

regulator/vaproizer

See, pressure regulator/vaporizer in LP fuel system

section

Inspect LP mixer

(standard LP truck)

See, LP mixer in LP fuel system section.

Inspect variable venturi air/fuel

mixer (low emission LP truck)

See, Variable Venturi Air/Fuel Mixer in LP fuel system

(Low emission version) section.

Inspect complete exhaust

system for leaks, damage

●

Pertorm Visual inspection of exhaust system.

●

Repair any/all leaks found.

Engine Control Unit (ECU) and

others (low emission LP truck)

The commander, oxygen sensor and vacuum control

solenoid are not serviceable. If faulty, they must be

replaced. See Trouble Shooting Section.

5

4

3

2

1

6

Loading...

Loading...