417102012_LMI02.doc - 63 - Rev. 9-07.08

6 Installation

6.1 Mechanical connection

6.1.1 Installation of conductivity measuring and control instrument LMI 02

The conductivity measuring and control instrument LMI 02 is designed as a wall-mounted

instrument and is fixed in place with 4 screws.

6.1.2 Pipe installation (flow-through fitting)

WARNING

The cross hole of the Measuring head must lie parallel to the tubular axle i.e. in the flow

direction of the medium.

NOTE

Deviations can lead to falsification of measuring values (eddy). The fitting position can be

controlled by marking arrows on the adapter of the Measuring head. The preferred set-up

would be vertical piping with flow direction from bottom to top.

The distance between the sensor and instrument should not exceed 20 m.

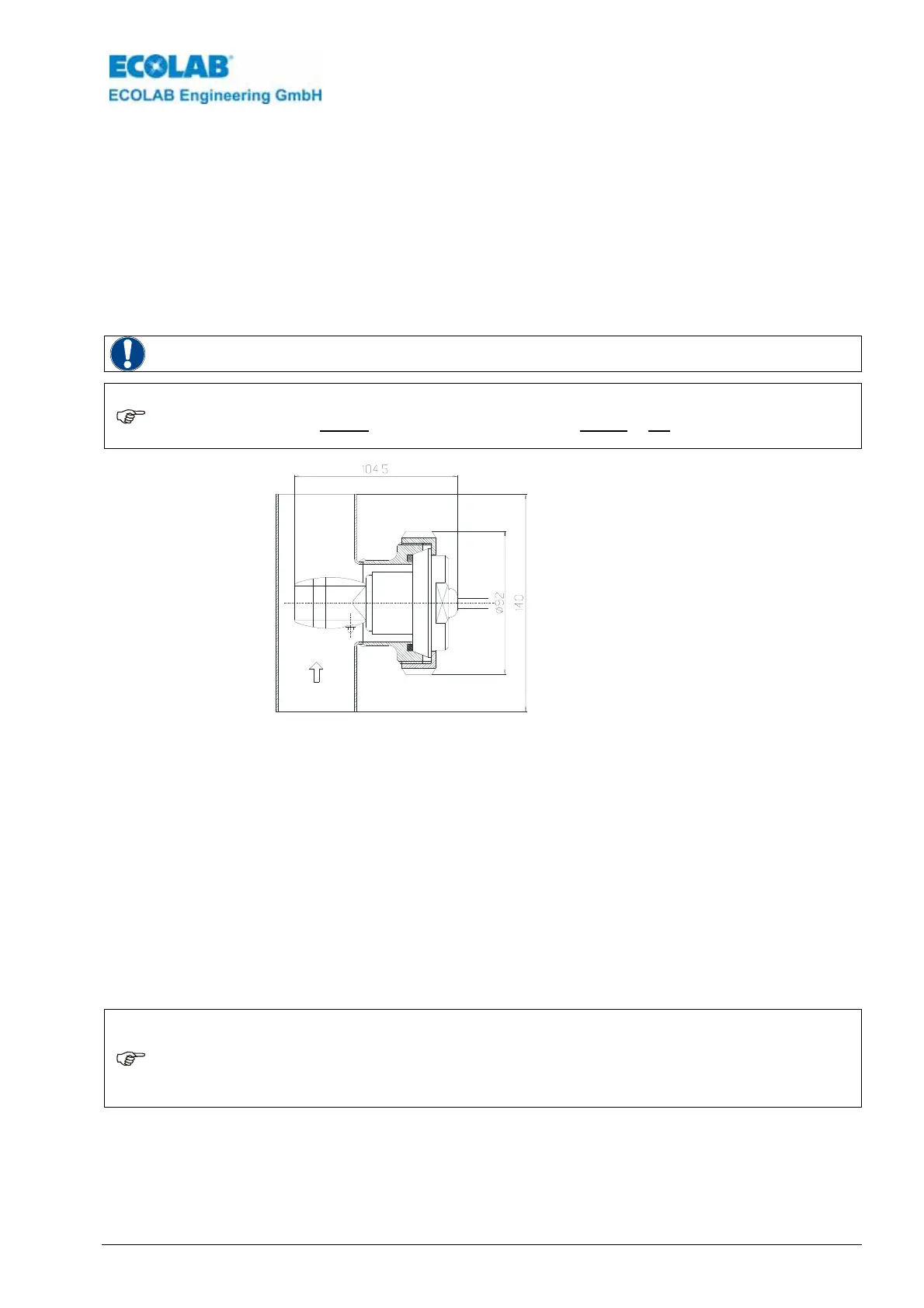

fig 6.1

Installation

Item no. for conductivity probe 0.2m in PEEK

with PVDF adapter: 287604

Item no. for conductivity probe 0.2m in PP

with PP adapter: 287622

Item no. for flow-through fitting 287507

Fix the

conductivity probe in the flow-through fitting and tighten with a coupling ring.

Pipe connection:

Type: Flow-through fitting (DIN 11851)

Material: 1.4301

Diameter: DN 50

Conductivity probe connection:

Type: Milk pipe fitting (DIN 11851)

Material: PEEK or PP

Diameter: DN 50

6.1.3 Tank wall installation

NOTE

The installation location must be selected so that sufficiently thorough mixing is ensured

in the area of the conductivity probe, and it must be at a considerably lower level than the

minimum level of the detergent solution even during running circulation. The transverse

borehole of the conductivity probe must be set up vertically or at an angle of up to max.

45°. The distance between the conductivity probe and instrument should be no more than

20 m.

Loading...

Loading...