DVC6000f Series

Errata Sheet

April 2007

4

insulation screen and sheath. The screen should be

connected to the ground.

7. An appropriate heat-resistant cable should be

selected for use with the controller in an application

where the ambient temperature exceeds 70_C.

8. When using and maintaining the product in the

field, cleaning the plastic surface of the product with

dry cloth is strictly prohibited to avoid the risk of

producing electrical spark.

9. The user must not be allowed to replace at will

the electric components of the product on his own to

avoid damage to the intrinsically safe performance of

explosion protection of the product.

10. The user must follow the relevant rules specified

by the product instruction manual, the “13th Section

of Electric Equipment Used in Explosive Gaseous

Environment: Maintenance of Electric Equipment

Used in Explosive Gaseous Environment” of

GB3836.13-1997 standard, the “15th Section of

Electric Equipment Used in Explosive Gaseous

Environment: Electric Installation in Hazardous

Locations (except for coal mine)” of

GB3836.15-2000 standard and the “Electric

installation construction and acceptance test code

for electric equipment mounting engineering in an

explosive and fire-hazardous environment” of

GB50257:1996 standard while performing

installation, operation, and maintenance for the

product.

NEPSI Flameproof

DVC6000f Series digital valve controllers

(designated as controller hereafter) have been

proved to be in conformity with the requirements

specified in the national standards GB3836.1-2000

and GB3836.2-2000 through inspections conducted

by National Supervision and Inspection Centre for

Explosion Protection and Safety of Instrumentation

(NEPSI). The Ex markings for the products are Ex d

II B+H2T6/T5 (DVC6010f, DVC6020f, and

DVC6030f only), Ex d II BT6/T5 (DVC6005f only),

and Ex d II CT6/T5/T4 (DVC6015, DVC6025, and

DVC6035 only) respectively and their Ex certificate

number is GYJ06279. When using the product , the

user should pay attention to the items stated below:

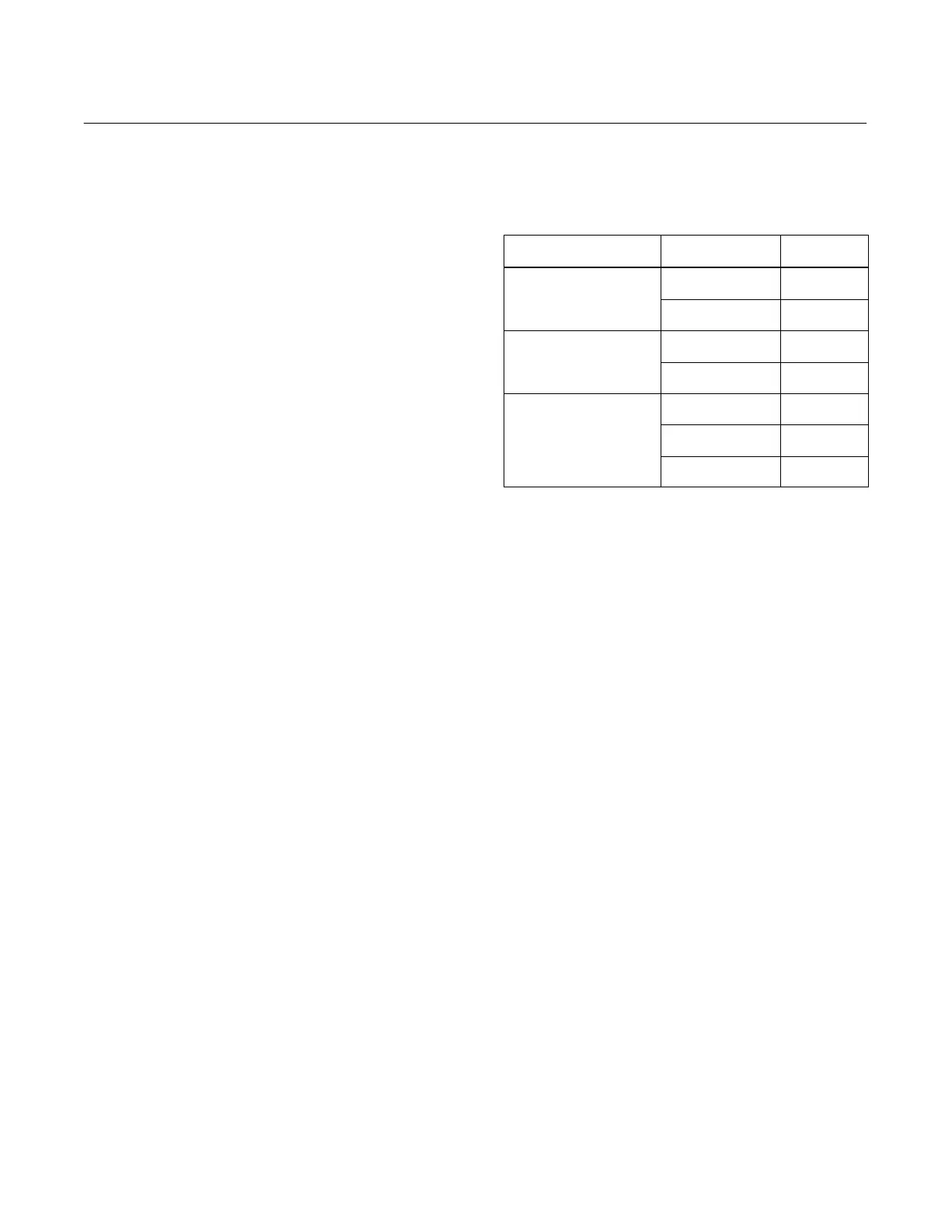

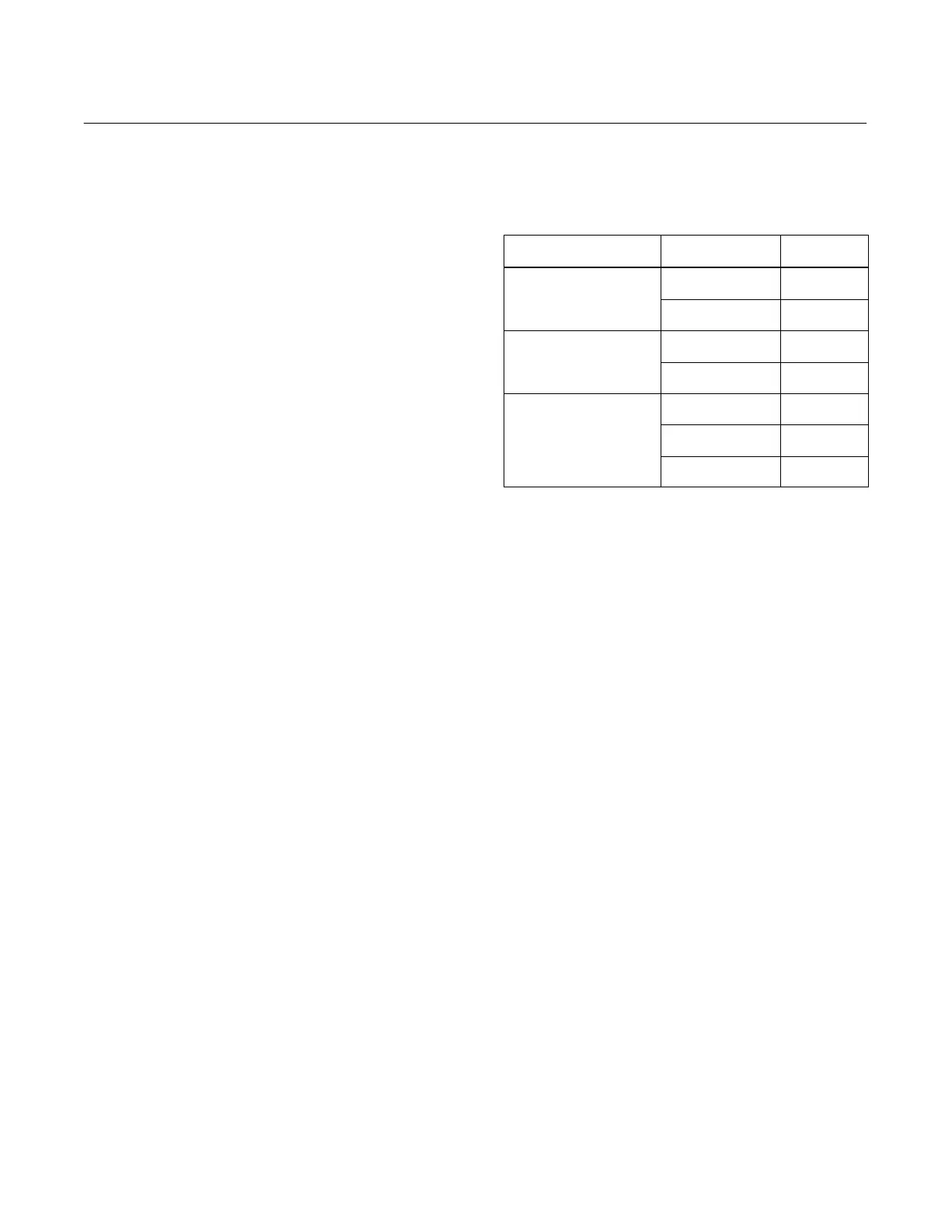

1. The correlation of this approved DVC6000f

Series digital valve controllers in specific product

type, Ex marking, and operating ambient

temperature is as follows:

Product Type Ex Marking

Ambient

Temperature

DVC6010f, DVC6020f,

DVC6030f (integral design)

Ex d II B+H

2

T6

−40_C to

+75_C

Ex d II B+H

2

T5

−40_C to

+80_C

DVC6005f (main unit of

separate design)

Ex d II BT6

−40_C to

+75_C

Ex d II BT5

−40_C to

+80_C

DVC6015, DVC6025,

DVC6035 (feedback units

of separate design

Ex d II CT6

−60_C to

+80_C

Ex d II CT5

−60_C to

+95_C

Ex d II CT4

−60_C to

+125_C

2. The enclosure of the controller provides a

grounding terminal, and the user should install a

reliable grounding wire connected to it when

mounting and using the controller.

3. The controller’s cable entrance (1/2 NPT) must

be fitted with a cable entry device which is

Ex−approved through inspection of explosion

protection, in conformity with relevant standards of

GB3836.1-2000 and GB3836.2-2000 and has a

corresponding rating of explosion protection.

4. An appropriate heat−resistant cable should be

selected for use with the controller in an application

where the ambient temperature exceeds 70_C.

5. The principle of “Opening equipment’s cover is

strictly prohibited while its is active” must be abided

by when using and maintaining the controller in the

field.

6. The user must follow the relevant rules specified

by the product instruction manual, the “13th Section

of Electric Equipment Used in Explosive Gaseous

Environment: Maintenance of Electric Equipment

Used in Explosive Gaseous Environment” of

GB3836.13-1997 standard, the “15th Section of

Electric Equipment Used in Explosive Gaseous

Environment: Electric Installation in Hazardous

Locations (except for coal mine)” of

GB3836.15-2000 standard and the “Electric

installation construction and acceptance test code

for electric equipment mounting engineering in an

explosive and fire-hazardous environment” of

GB50257:1996 standard while performing

installation, operation, and maintenance for the

product.

Loading...

Loading...