Safety and operating instructions

26 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

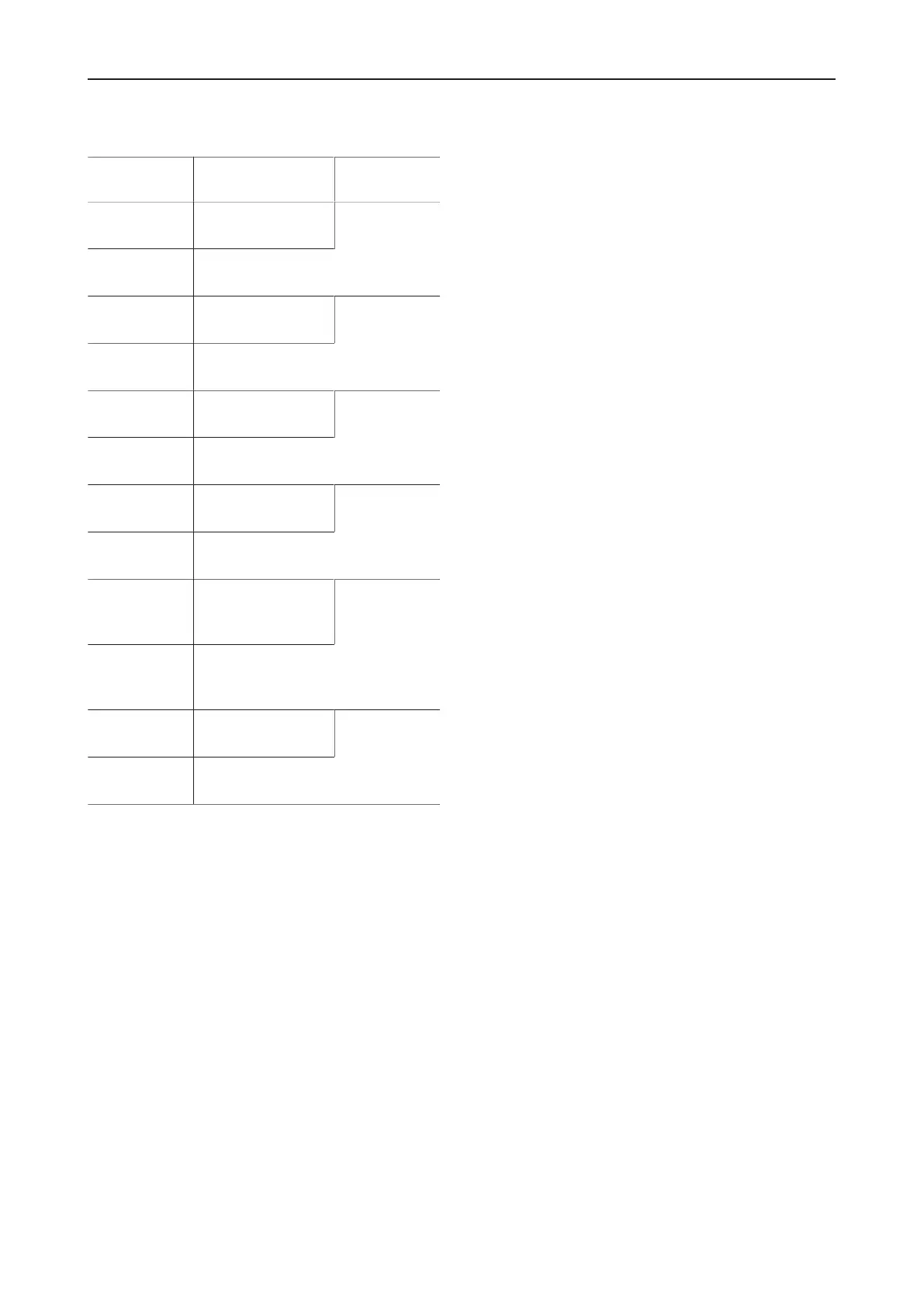

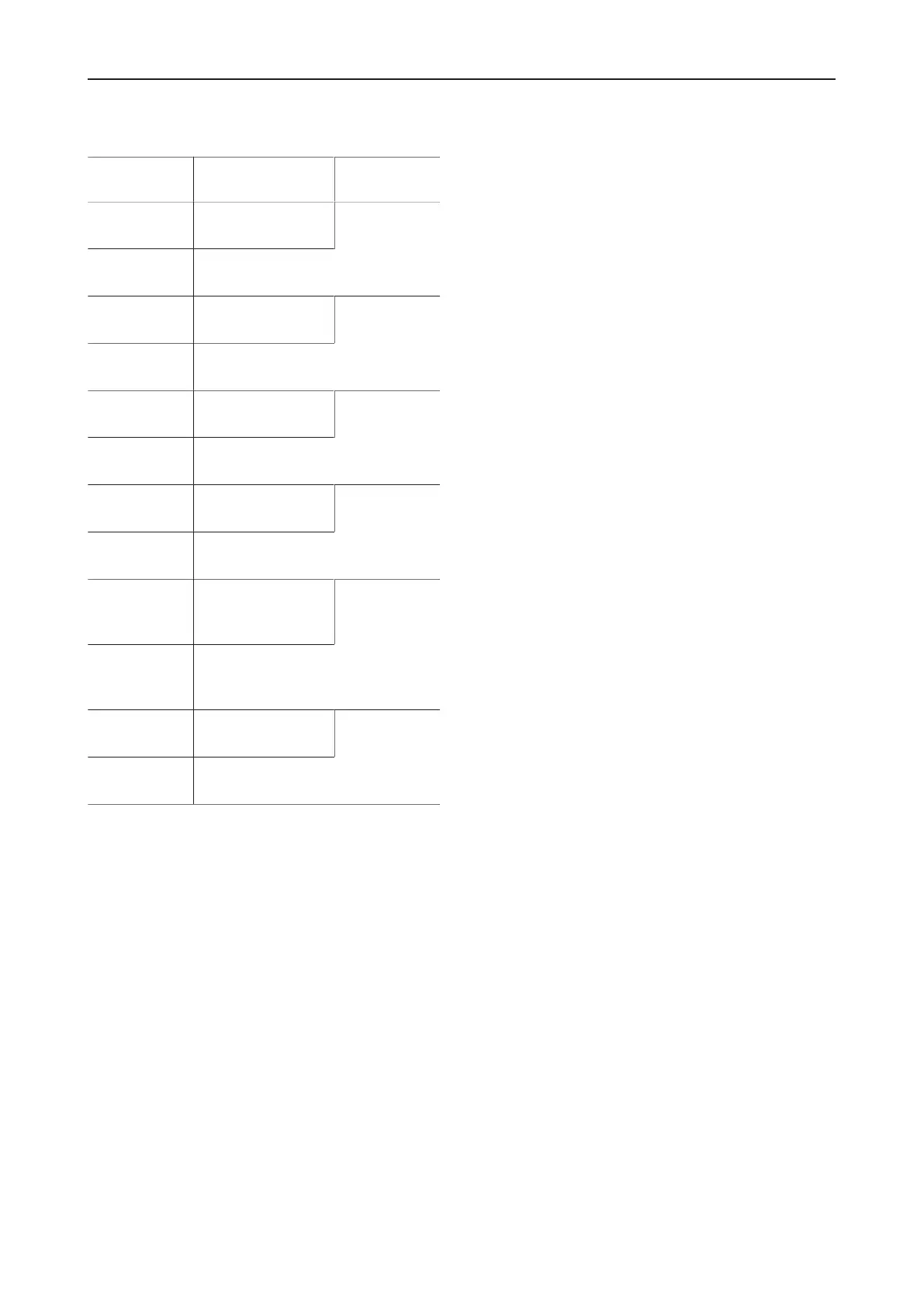

5.1.3 Gear oil

Temperature

range

Media /consum-

ables

Manufacturer

-20 to +30 °C

-4 to 86 °F

GPD 80

Spartan EP100

ESSO

-15 to +40 °C

5 to 104 °F

Spartan EP 220

Getriebeöl GPD90

-20 to +30 °C

-4 to 86 °F

Mobil Gear 80EP

Mobilube GX80

MOBIL

-15 to +40 °C

5 to 104 °F

Mobilube GX90

Mobil Gear630

-20 to +30 °C

-4 to 86 °F

Shell Spirax 80EP

Shell Omala oil100

SHELL

-15 to +40 °C

5 to 104 °F

Shell Omala oil220

Shell Spirax 90EP

-20 to +30 °C

-4 to 86 °F

EP SAE 80

Energol GR XP 68

BP

-15 to +40 °C

5 to 104 °F

EP SAE 90

Energol GR XP 220

-20 to +30 °C

-4 to 86 °F

Texaco Meropa 68

Universal Gear

Lubricant EP80

TEXACO

-15 to +40 °C

5 to 104 °F

Texaco Meropa 220

Universal Gear

Lubricant EP90

-20 to +30 °C

-4 to 86 °F

EP 80

Degol BG 68

ARAL

-15 to +40 °C

5 to 104 °F

EP 90

Degol BG 220

5.2 Preconditions for the carrier

The carrier must fulfil the following criteria in order that a

drum cutter can be attached to it:

• A complete hydraulic hammer or shearer line right to

the end of the carrier boom must be available.

• The motor's pressure line is set to max. 350bar

(5076psi).

• The pressure of the tank line is at least 5bar

(73psi) above the pressure of the hydraulic motor's

case drain line.

• The pressure in the leakage oil line is of 3bar

(44psi) maximum during operation.

• The cabin of the carrier must be protected by means

of suitable measures (e.g. armoured glass) against

damage due to flying rock.

• The cabin of the carrier must allow an adequate

view of the working area.

• Lighting with a minimum strength of 150Lux must

be attached to the carrier and this must be protected

against damage.

• An EMERGENCY STOP device must be available at

every operating and driving position and this must

always be functional.

• An acoustic warning signal with manual activation

must be available on the carrier and this must al-

ways be functional.

• All actuation elements present at the operating and

driving position must be equipped with a dead man's

switch.

• All purchased parts must comply with the specifica-

tions of the carrier manufacturer.

5.3 Preconditions for adapter

plate

The drum cutter is supplied with a rotatable upper part.

This rotatable upper part has a standardised hole pattern

so that it can be mounted to an adapter plate.

The mating areas of adapter plate must be ground plane

(surface roughness Ra12.5 / max. planeness deviation

0.5mm (0.02in.))

Note: The adapter plate is not included in the scope of

delivery of the drum cutter.

Loading...

Loading...