Safety and operating instructions

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

55

7.11 Replace cutter drum

The following maintenance activities are carried out in

the workshop.

n

You must replace the cutter drum:

• if the bearing surfaces of the pick boxes are worn.

• if the pick boxes are worn in the area of the snap

rings.

• if the pick boxes are broken.

• if the wear condition of the charging spiral is ir-

reparable.

DANGER Risk of death due to use of old parts

Using old parts (old hydraulic hoses, screws or retainers)

can lead to accidents, which may in turn result in severe

injuries.

u Only use new parts.

u Only use original parts.

Note: You need an assistant who supports you during

assembly and disassembly work.

WARNING Risk of injury due to negligence or in-

correct lifting procedure

Negligent or incorrect actions during the lifting of the cut-

ter drum can cause severe injuries.

u When lifting or lowering the cutter drum, always be

aware of the weight.

u Always execute all lifting procedures with heavy

parts using suitable lifting gear.

u If lifting procedures require the application of physical

force, personnel should always lift in pairs.

u Wear protective gloves and safety footwear.

7.11.1 Disassemble cutter drum ER100L -

ER2000L

Actual details may differ.

n

Disassemble the drum cutter from the carrier (see

chapter Removing the hydraulic attachment from

the carrier) and place on a level working area with

sufficient bearing strength.

n

Remove the adapter plate.

n

Lift the drum cutter using suitable lifting equipment

and suspend on a crane. Observe the weight (see

chapter Technical Specifications).

n

Place the drum cutter upright down a level working

area.

n

Secure the upright drum cutter against toppling by

suitable means.

n

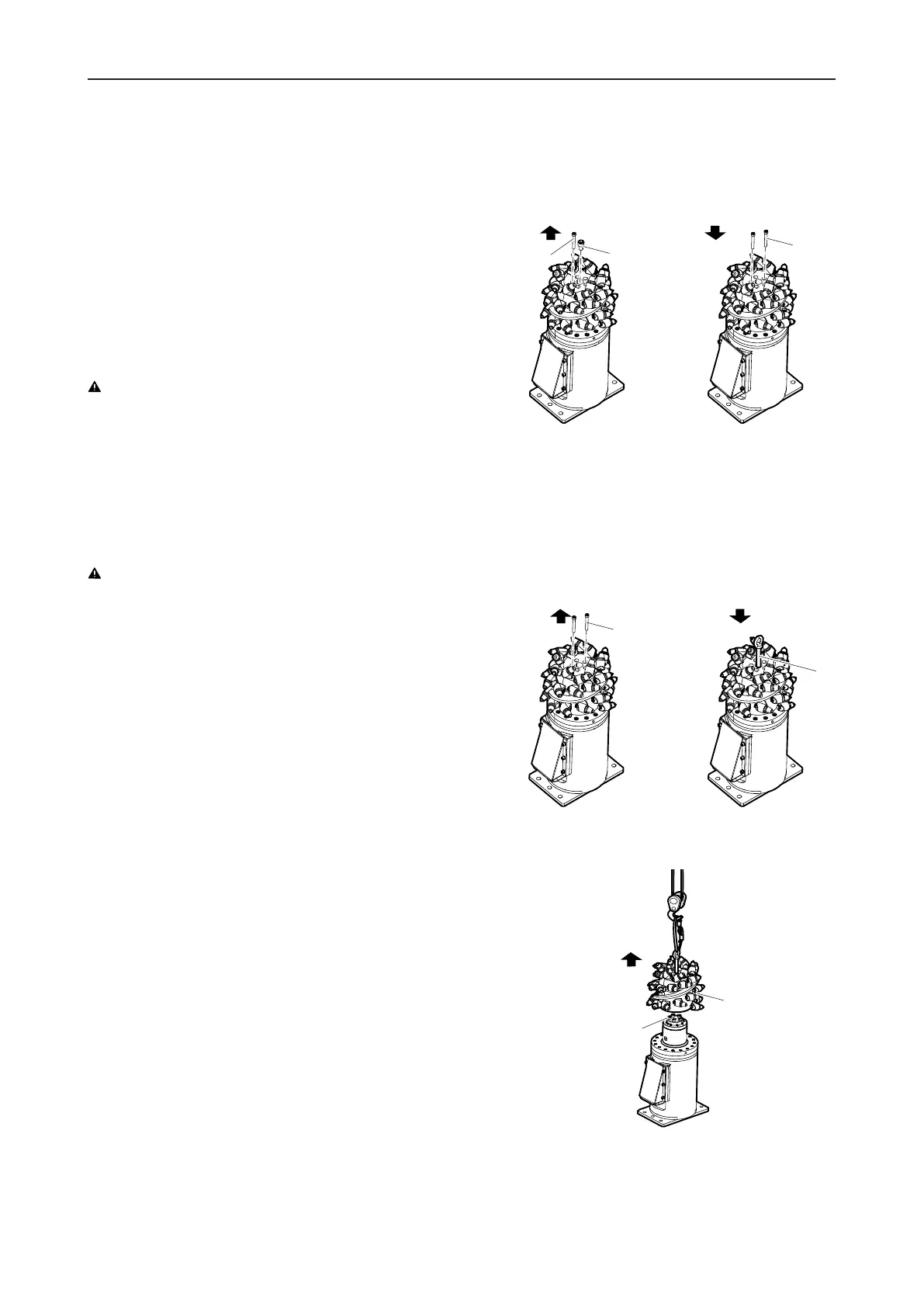

Remove the fastening screws(A) and facing

screws(B) of the cutter drum.

n

Screw disassembly screws(C) into the threaded

holes of the facing screws in diagonal sequence.

Through alternating screwing in of the disassembly

screws in diagonal sequence, the cutter drum is

pressed slowly upwards from the drive shaft.

n

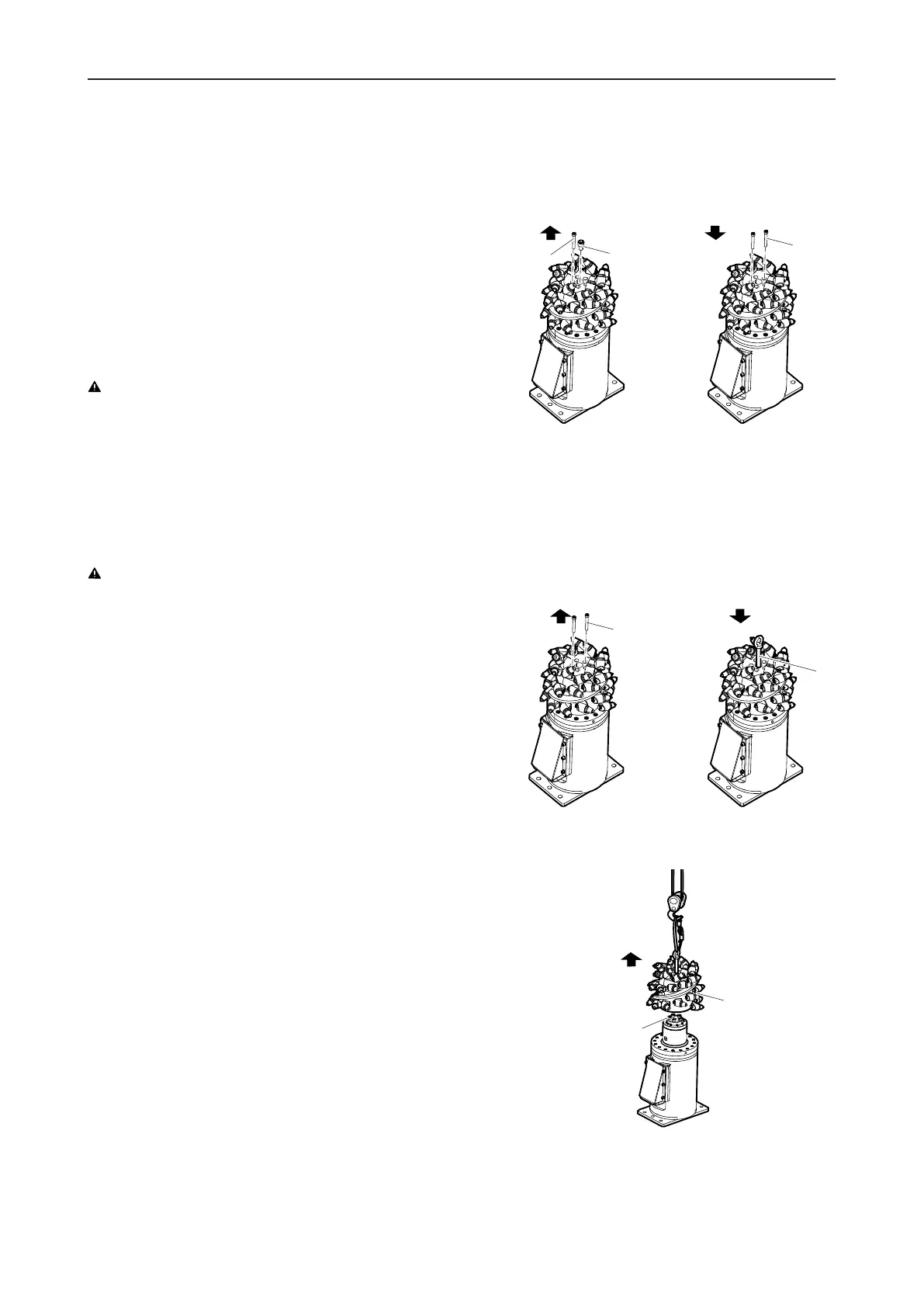

Remove the disassembly screws(C) and screw in an

eyebolt(D) as lifting device.

n

Carefully lift the cutter drum(E) from the drive shaft.

Loading...

Loading...