Safety and operating instructions

34 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

WARNING Risk of fatal injury due to a failure to

observe the required tightening torques

Accidents can happen due to negligence and these

can lead to severe injuries or damage to property.

u Tighten the hexagonal receiver with the required

tightening torque.

n

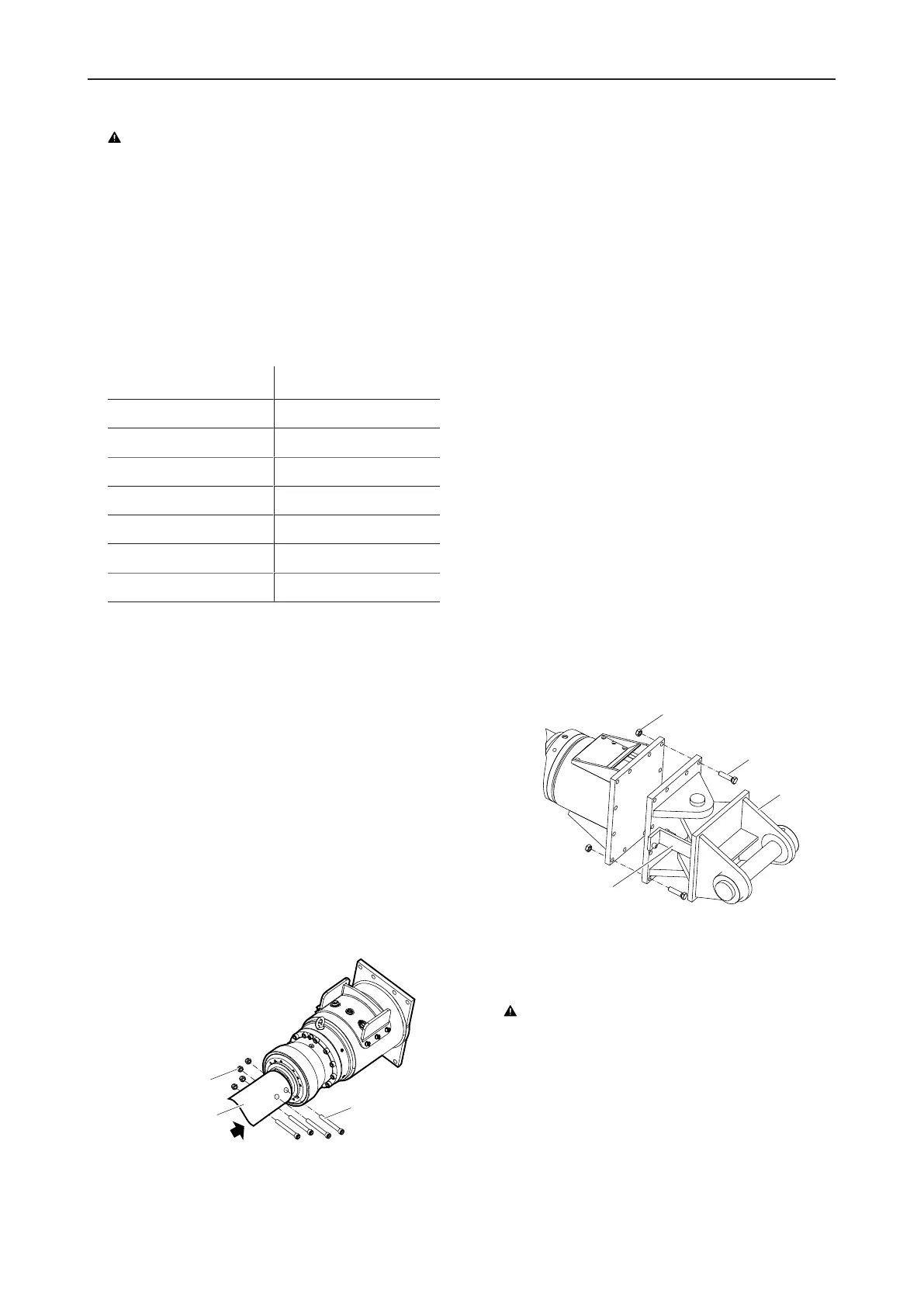

Insert the fastening screws(N) into the hexagonal re-

ceiver.

n

Tighten the fastening screws with the required tight-

ening torque in a diagonal sequence.

Type Tightening torque

ER 100 L 300 Nm (221 ft lbs)

ER 250 L 300 Nm (221 ft lbs)

ER 400 L 300 Nm (221 ft lbs)

ER 450 L 300 Nm (221 ft lbs)

ER 600 L 950 Nm (701 ft lbs)

ER 1500 L 950 Nm (701 ft lbs)

ER 2000 L 1400 Nm (1033 ft lbs)

n

Insert the facing screws in the disassembly screw

apertures and tighten.

5.6.2 Mount drilling auger

Actual details may differ.

1.

Place the drilling auger on a level working area with

sufficient bearing strength and secure against rolling

off.

2.

The drum cutter is attached to the carrier.

3.

Push the hexagon of the drive shaft of the drum cut-

ter fully into the hexagonal receiver of the drilling

auger(Q). The holes of the drilling auger must flush

with the notches of the hexagon of the drive shaft.

4.

Switch off the carrier and safeguard against a restart.

5.

Fix the fastening screws(P) and nuts(O) and tighten

as required.

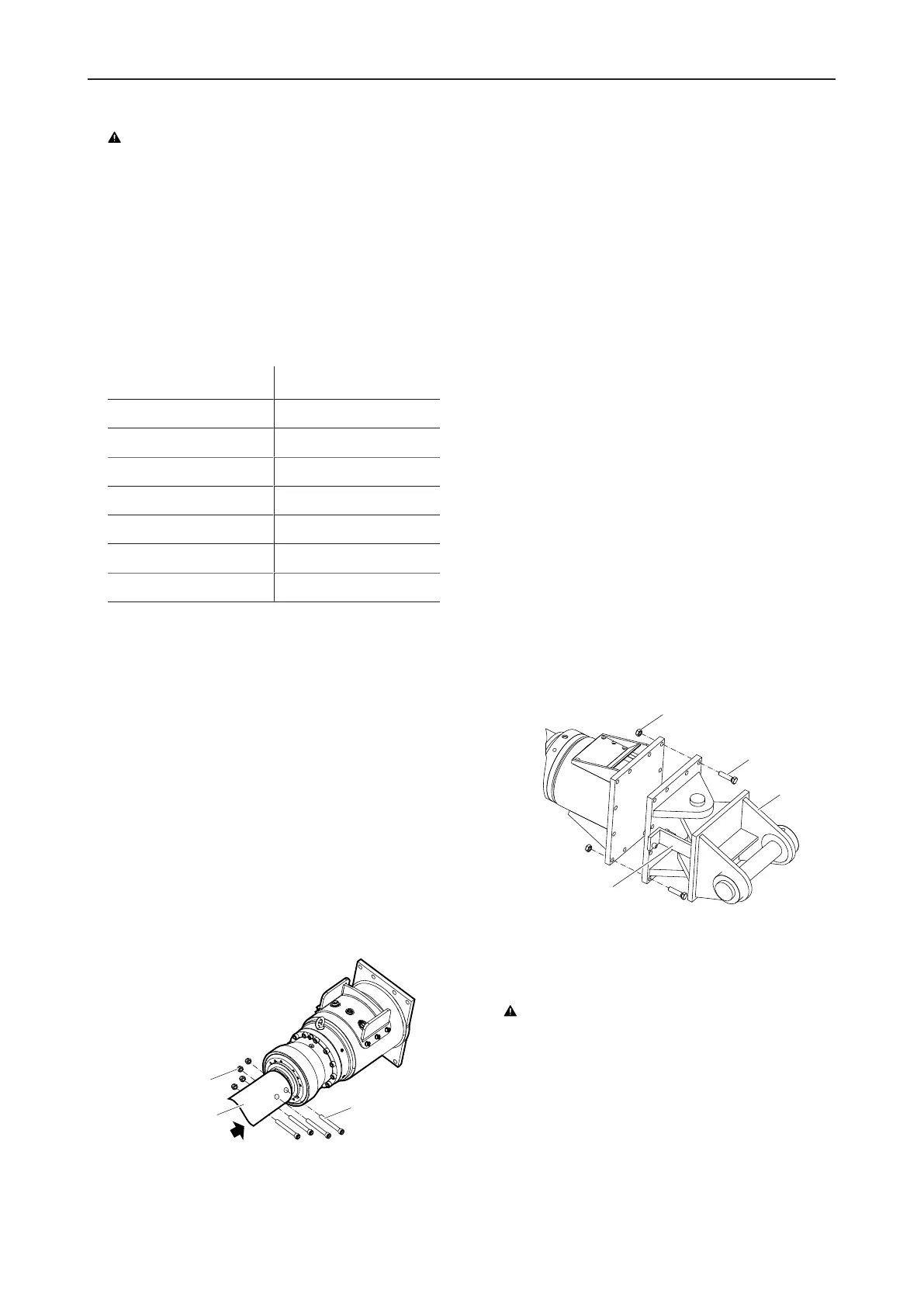

5.6.3 Mount pivot adapter

Actual details may differ.

Note: When attaching a drilling auger it is necessary to

mount a pivot adapter to the drum cutter instead of the

adapter plate.

You need an assistant to attach the pivot adapter.

n

Agree on hand signals with your assistant, to enable

him to help you placing the parts to be attached.

NOTICE Pivot adapter can come loose

The pivot adapter can come loose if the fastening

screws are not designed for local high loads.

u Only use the Allen screws of strength category 8.8 to

attach the pivot adapter.

n

Remove the adapter plate from the drum cutter (see

chapter Removing the hydraulic attachment from

the carrier).

n

Place the drum cutter on a level working area with

sufficient bearing strength within the range of the car-

rier.

n

Align the pivot adapter(T) with the drum cutter.

n

Insert two screws(S) and fix with nuts(R).

n

Insert the remaining screws(S) and nuts(R) in diago-

nal sequence and tighten as required.

WARNING Risk of fatal injury due to a failure to

observe the required tightening torques

Accidents can happen due to negligence and these

can lead to severe injuries or damage to property.

u Tighten the pivot adapter with the required tight-

ening torque.

Loading...

Loading...