Fixating the Ink

After printing, the T-shirt is processed in a heat press or

oven to fixate the ink.

Precautions when Fixating the

Ink

❏ If you use a heat press with a T-shirt (media) that

has printing near the seams such as the sleeves,

fixation may not be performed correctly as ink is

not heated sufficiently due to the difference of levels

in the seams.

We recommend placing a heat-resistant fabric

above and below the T-shirt and applying pressure

as shown below to reduce the difference in levels.

❏ If the ink is not fixated sufficiently, colors may come

out in the wash or when rubbing against something.

❏ If the T-shirts (media) have plastic buttons or

zippers, we recommend that you first confirm

whether or not they will be damaged before using

the heat-press.

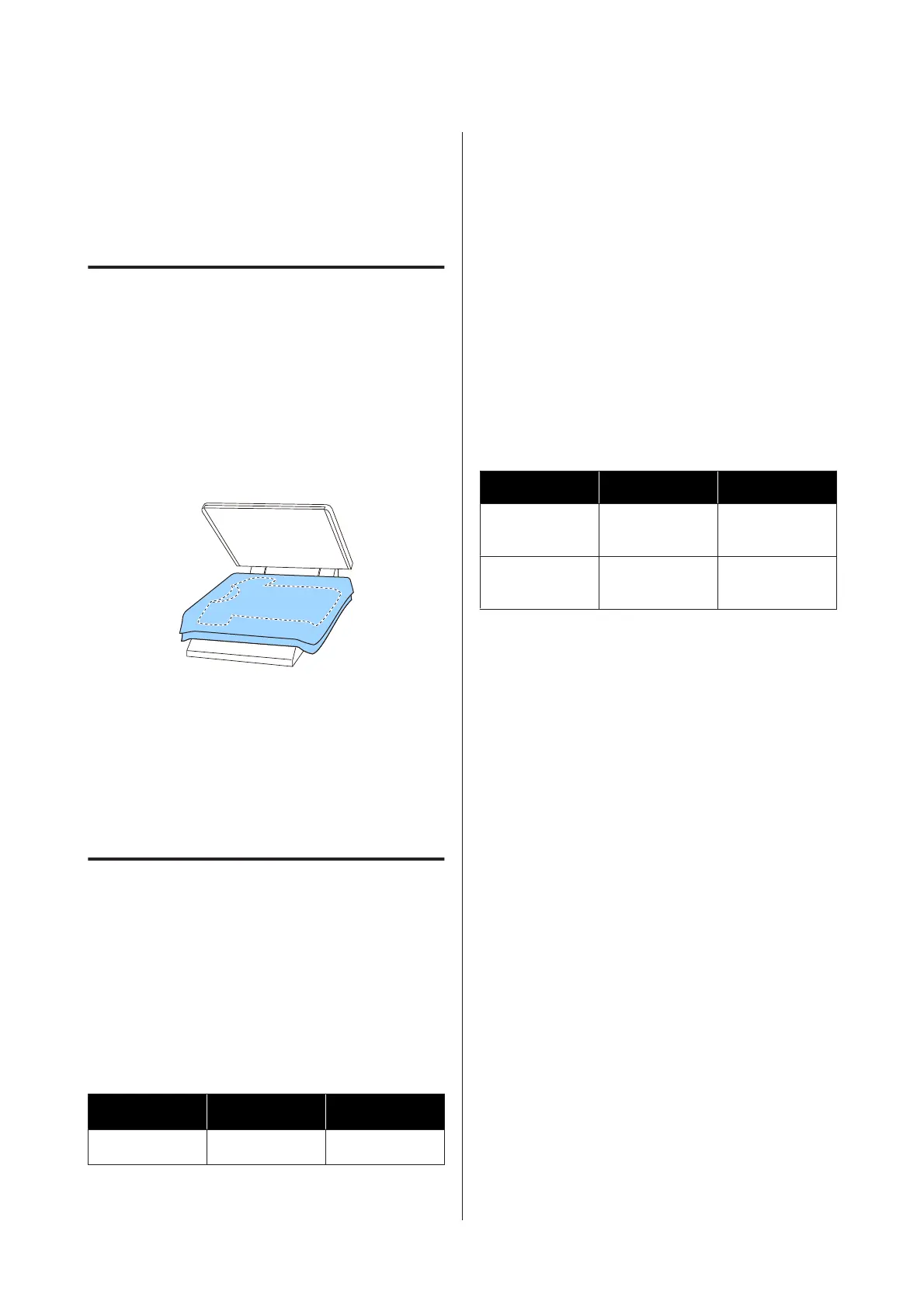

Fixating conditions

The conditions required for fixating differ as shown

below according to the heat press or oven.

Use the following values as a guide. The optimum

conditions vary depending on the type of heat press or

oven, and the amount of ink.

Heat press

Temperature Time

Pressure

*1

170 ˚C

45 seconds

*2

4.2 N/cm

2

*1 The optimum conditions vary depending on the

type of heat press such as the manual adjustment

type. Be sure to test the ink fixation result in

advance to find the right pressure.

*2 Images larger than A4 that have White ink may

take longer than 45 seconds to dry. Try extending

the time up to 90 seconds while checking if the ink

is dry.

Oven

Because the optimum conditions vary depending on the

oven, test and check the ink fixation result in advance to

determine the temperature and duration.

Type of Oven Temperature Time

Batch type 160 ˚C 3.5 to 5

minutes

*2

Conveyor type

160 ˚C

*1

3.5 to 4.5

minutes

*2

*1 Temperature of the fixating surface of the T-shirt.

Not the internal temperature. If the surface of the

T-shirt exceeds 180 ˚C, the T-shirt and the print

surface may change color.

*2 Images that have White ink require the maximum

fixating time (batch type: 5 mins., conveyor type:

4.5 mins.).

SC-F2100 Series User's Guide

Basic Printing

57

Loading...

Loading...