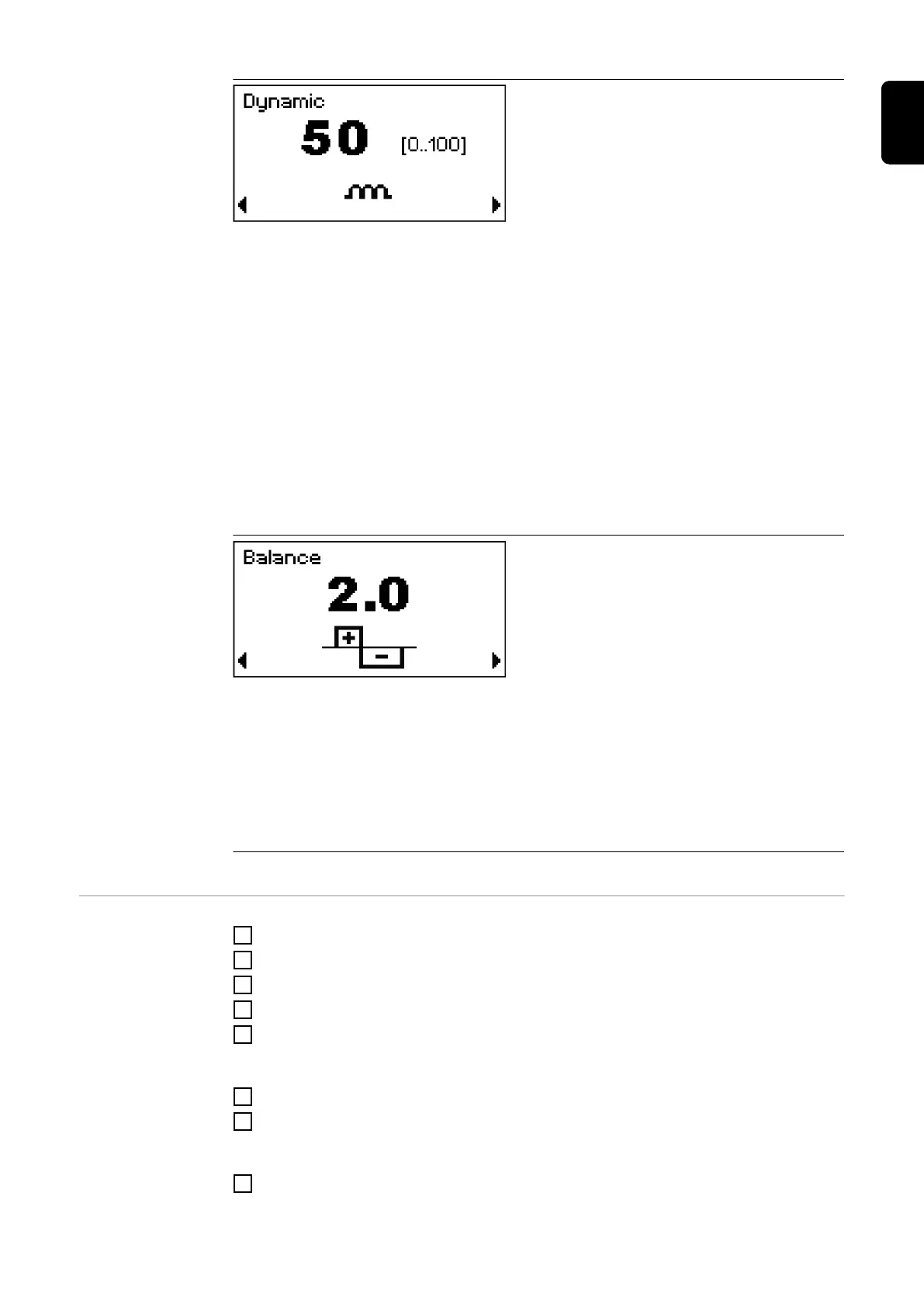

To obtain optimum welding results, it will sometimes be necessary to adjust the arc-

force dynamic.

Unit % (of main current)

Setting range 0 - 100

Factory setting 20

0 soft, low-spatter arc

100 harder, more stable arc

Functional principle:

at the instant of droplet transfer or in the event of a short circuit, there is a momentary

rise in amperage. In order to obtain a stable arc, the welding current is temporarily

increased. If the rod electrode threatens to sink into the weld pool, this measure pre-

vents the weld pool solidifying, as well as preventing more prolonged short circuiting of

the arc. This largely prevents the rod electrode from sticking.

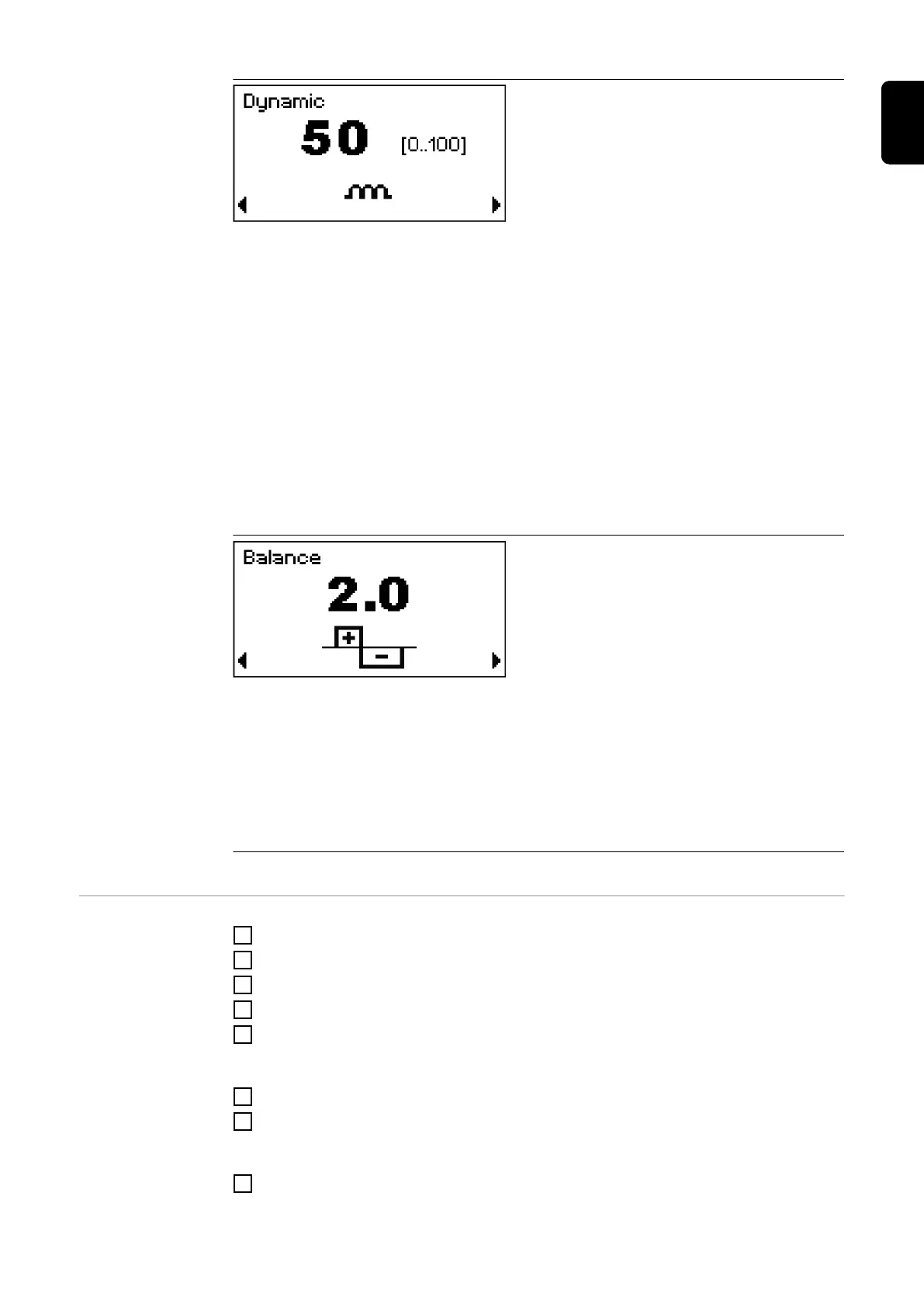

only with MagicWave for the manual metal arc AC welding process

Unit 1

Setting range -5 - +5

Factory setting 0

-5: highest fusing power, lowest cleaning action

+5: highest cleaning action, lowest fusing power

Preparation

1

Switch off cooling units (set setup parameter C-C to OFF)

2

Move the mains switch to the "O" position

3

Disconnect the mains plug

4

Remove the TIG welding torch

5

Plug the grounding cable in and latch it into place:

- for MagicWave: in the grounding cable connection

- for TransTig: in the (+) current socket

6

Use the other end of the grounding cable to establish a connection to the workpiece

7

Plug in the electrode cable and twist it clockwise to latch it into place:

- for MagicWave: in the welding torch connection

- for TransTig: in the (-) current socket

8

Plug in the mains plug

65

EN

Loading...

Loading...