TROUBLESHOOTING

REV6 /REV2 OI 248 (EN) 65

8.3.1 Austausch einer Gasverbindung

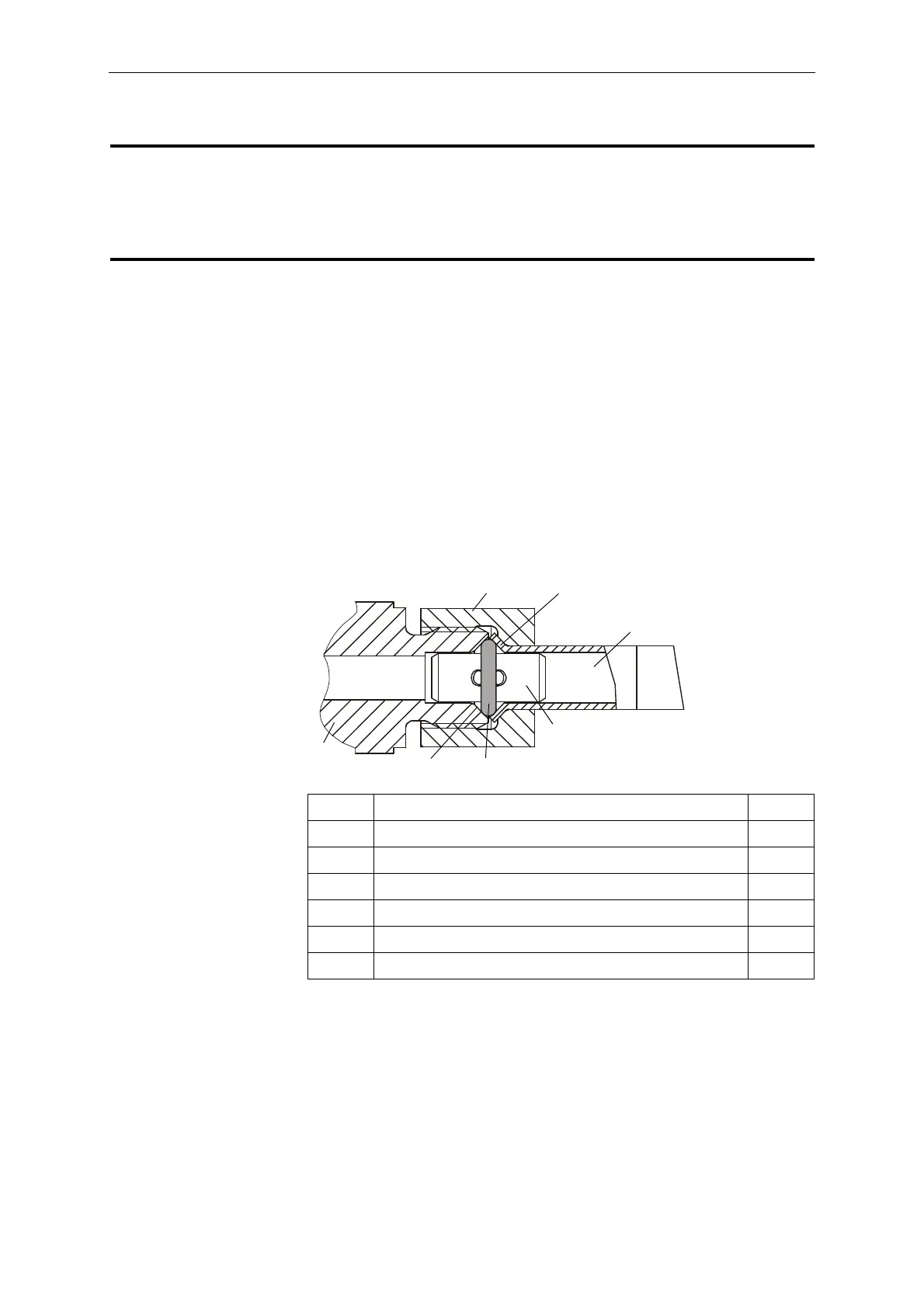

The standard gas connection consists of bent tubes. It is firmly

connected to the density monitor unit on one side. The other side

has a filling coupling with check valve for connection to the pole

columns.

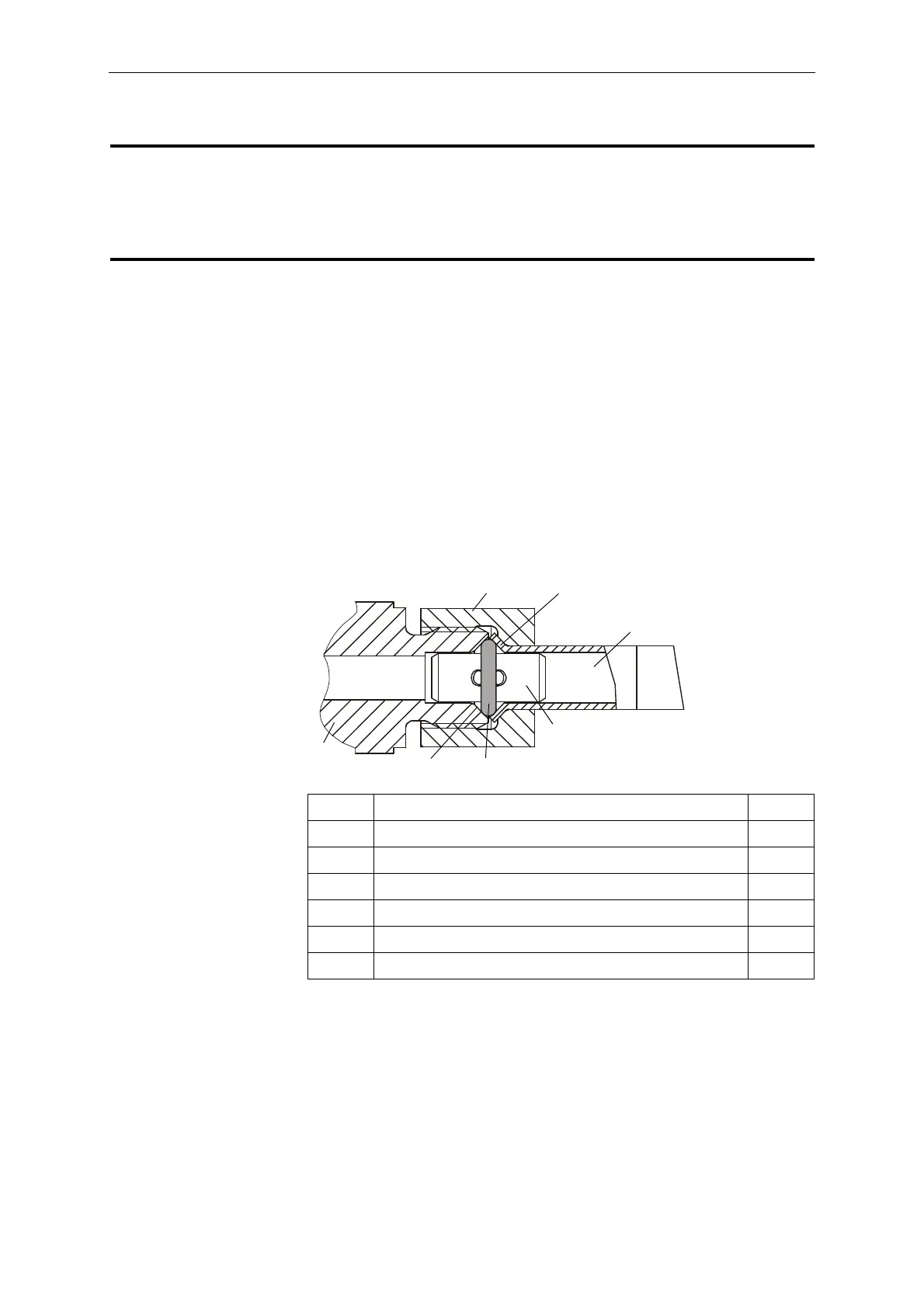

The ends of the gas pipes (1) are flared (1a). The inner surface of

the flaring is the sealing surface. The gas pipes are connected by

union nuts (1b). The flaring allows the union nuts to be captivated

to the gas pipe.

The piping junction points (2) have an external thread and an inside

tapered contour (2a). The inside tapered contour forms the sealing

surface.

A tubular stiffener (3) stabilizes the joint mechanically. The O-ring

(4) fitted onto the stiffener seals the connection.

• Disconnect all filling connections. This will disconnect the gas

compartments of the pole columns from the gas piping.

• Unscrew the gas pipe that is to be replaced from the junction

points.

• Check the sealing surfaces of the junction points for damage.

• Apply grease to a new O-ring (4) as per L5 and fit onto the tubular

stiffener (3).

• Lubricate the sealing areas on the gas pipe and the junction

points as per L5.

In one equipment version, the switchgear is available with a gas

connection of type FlexLink.

The FlexLink technology makes it particularly easy to couple the

gas connections to the pole columns. (see Chapter “12.2” on

page 101)

1 Gas pipe 1x

1a Flaring -

1b Union nut -

2 Junction point -

2a Inside tapered contour -

3 Tubular stiffener 1x

4 O-ring 1x

Loading...

Loading...