Troubleshooting

2031504-159D MAC™ 800 3-3

Visual Inspection

A thorough visual inspection of the equipment can save time. Small

things—disconnected cables, foreign debris on circuit boards, missing

hardware, loose components—can frequently cause symptoms and

equipment failures that may appear to be unrelated and difficult to

track.

NOTE

Take the time to make all the recommended visual checks before

starting any detailed troubleshooting procedures

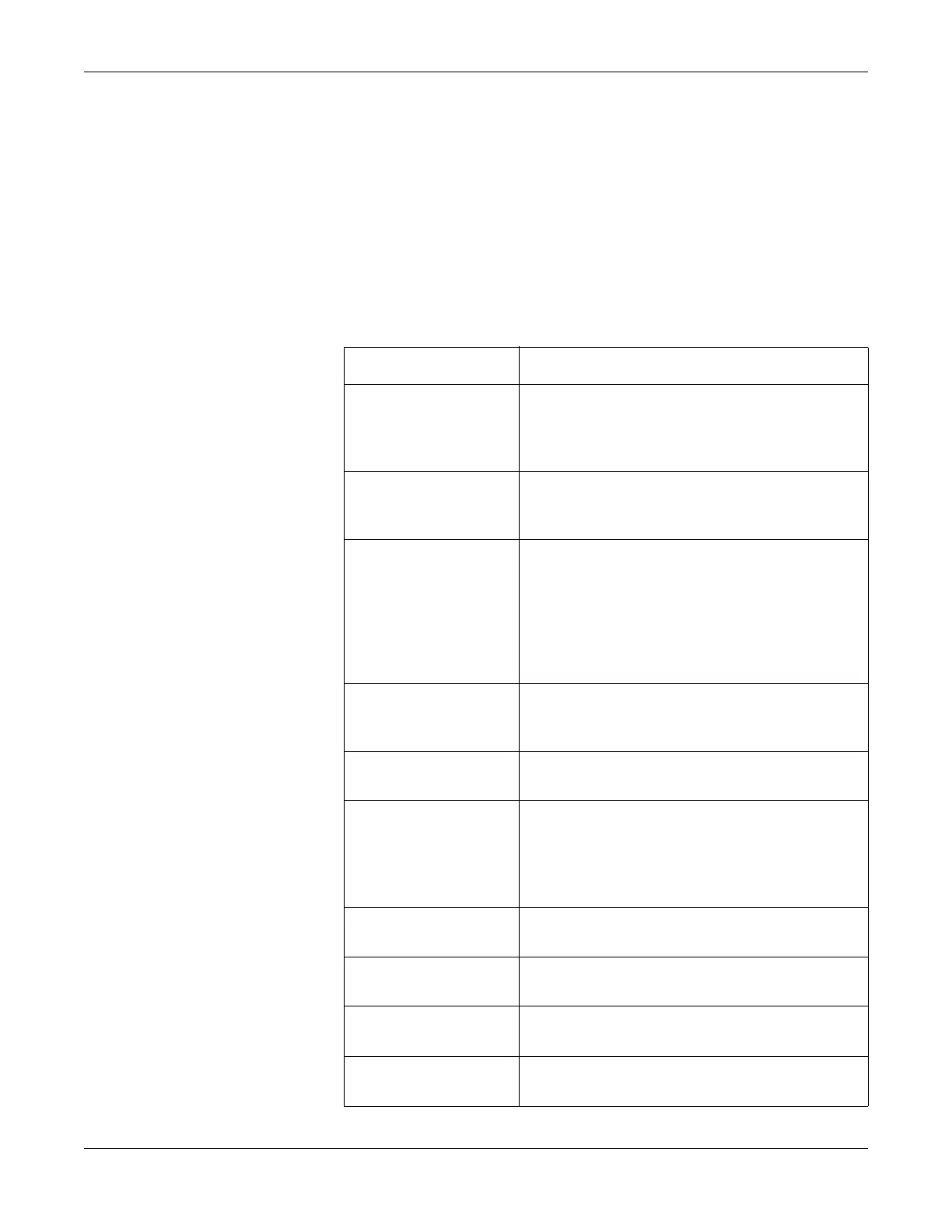

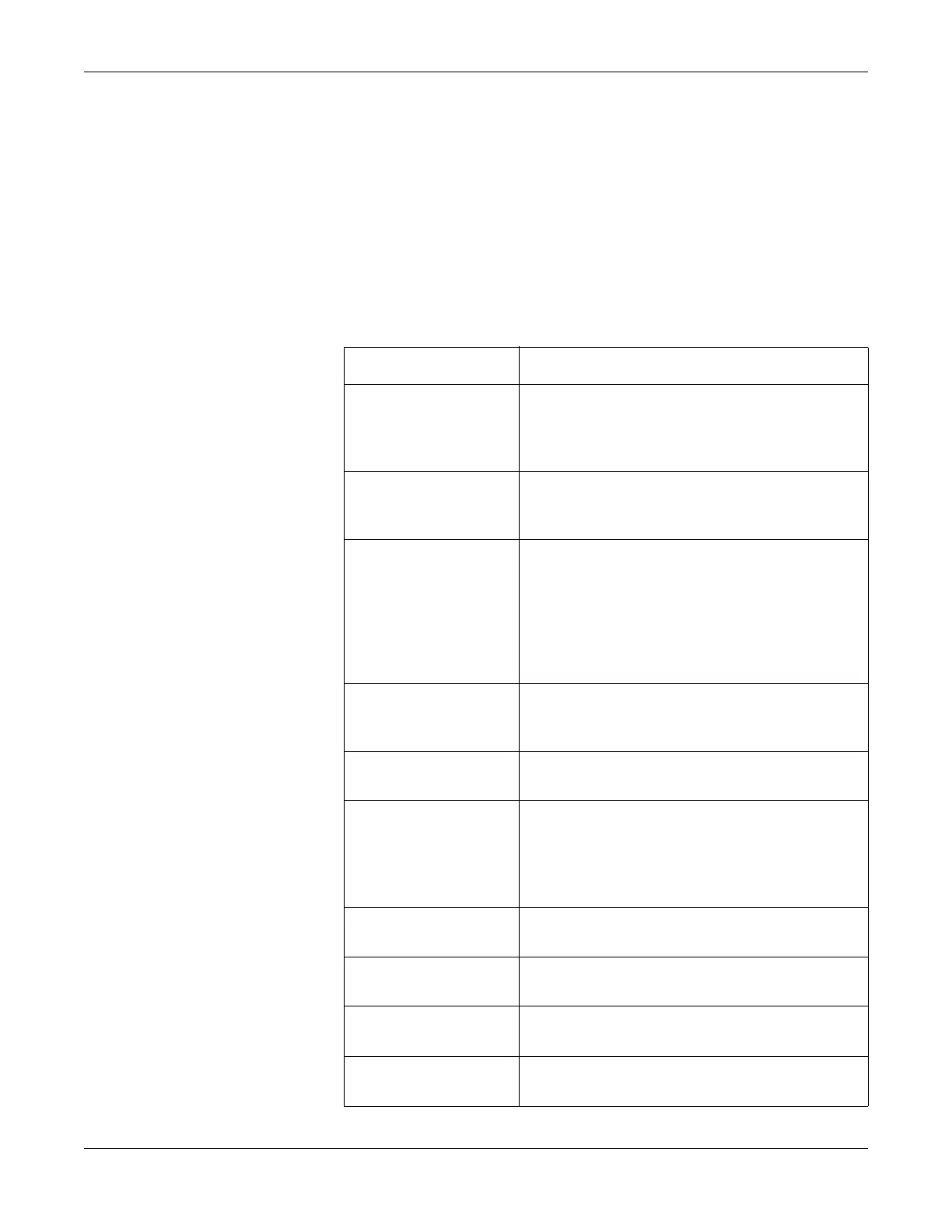

If the area is… Look for…

I/O Connectors and Cables

AC power cord

Fraying or other damage

Bent prongs or pins

Cracked housing

Loose screws in plugs

Interface cables

Excessive tension or wear

Loose connection

Strain reliefs out of place

Circuit boards

Moisture, dust, or debris (top and bottom)

Loose or missing components

Burn damage or smell of over-heated components

Socketed components not firmly seated

PCB not seated properly in edge connectors

Solder problems: cracks, splashes on board, incomplete

feedthrough, prior modifications or repairs

Ground wires/Wiring

Loose wires or ground strap connections

Faulty wiring

Wires pinched or in vulnerable position

Fasteners Loose or missing screws or other hardware, especially

fasteners used as connections to ground planes on PCBs

Power source

Faulty wiring, especially AC outlet

Circuit not dedicated to system

NOTE

Power source problems can cause static discharge,

reading problems, and discharge.

Keyboard

Cuts or cracks in the keyboard membrane

Unreadable labels

LCD display filter Scratches or cracks in the display filter (transparent part of

keyboard bezel) that impair viewing

Battery pack

Cracks, swells, or leaks in the battery casing

Dirt, scratches, or debris on contacts

SD card

Cracks

Dirt, scratches, or debris on contacts

Loading...

Loading...