AVy - HGB

Ch.5 86

5.8.3. Calculation of generic external braking resistor to be combined with the

internal braking unit with an approximate method

In order to calculate resistor values different from the one stated in the table 5.8.2.1 (having, for example,

different values of turn-on threshold of the braking unit), the following remarks are valid:

the peak power dissipated by the resistor is P

PBR

= V

BR

2

/ R

BR

[W] , where “V

BR

” is the turn on voltage of the

braking unit (see table 5.8.2.2 ).

The requested maximum power P

MB

by the cycle must not be higher than this value: P

MB

≤ P

PBR

.

The braking resistor is normally used with an intermittent cycle. Therefore it is possible to use a resistor

capable of a continuous dissipated power lower than P

MB

.

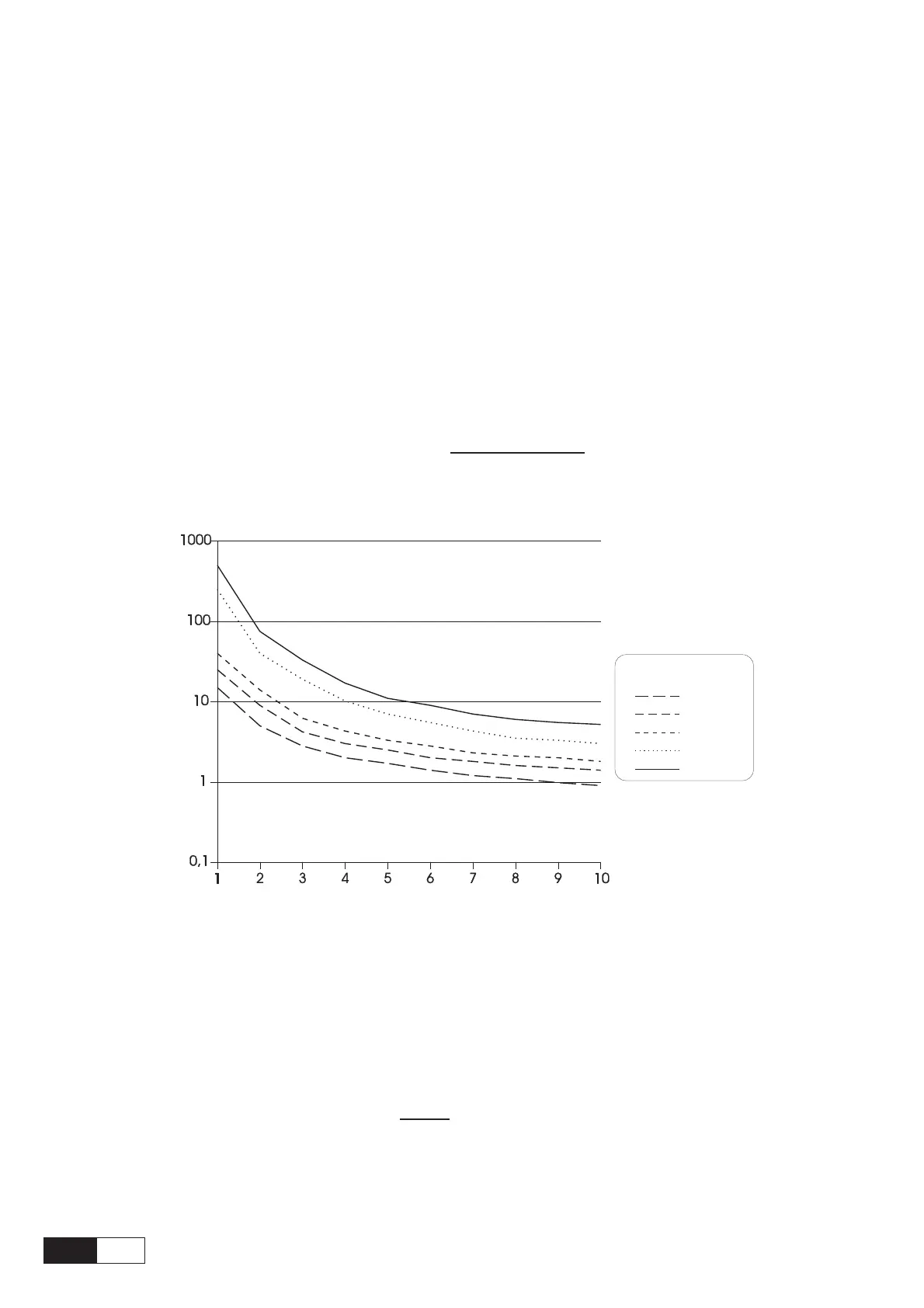

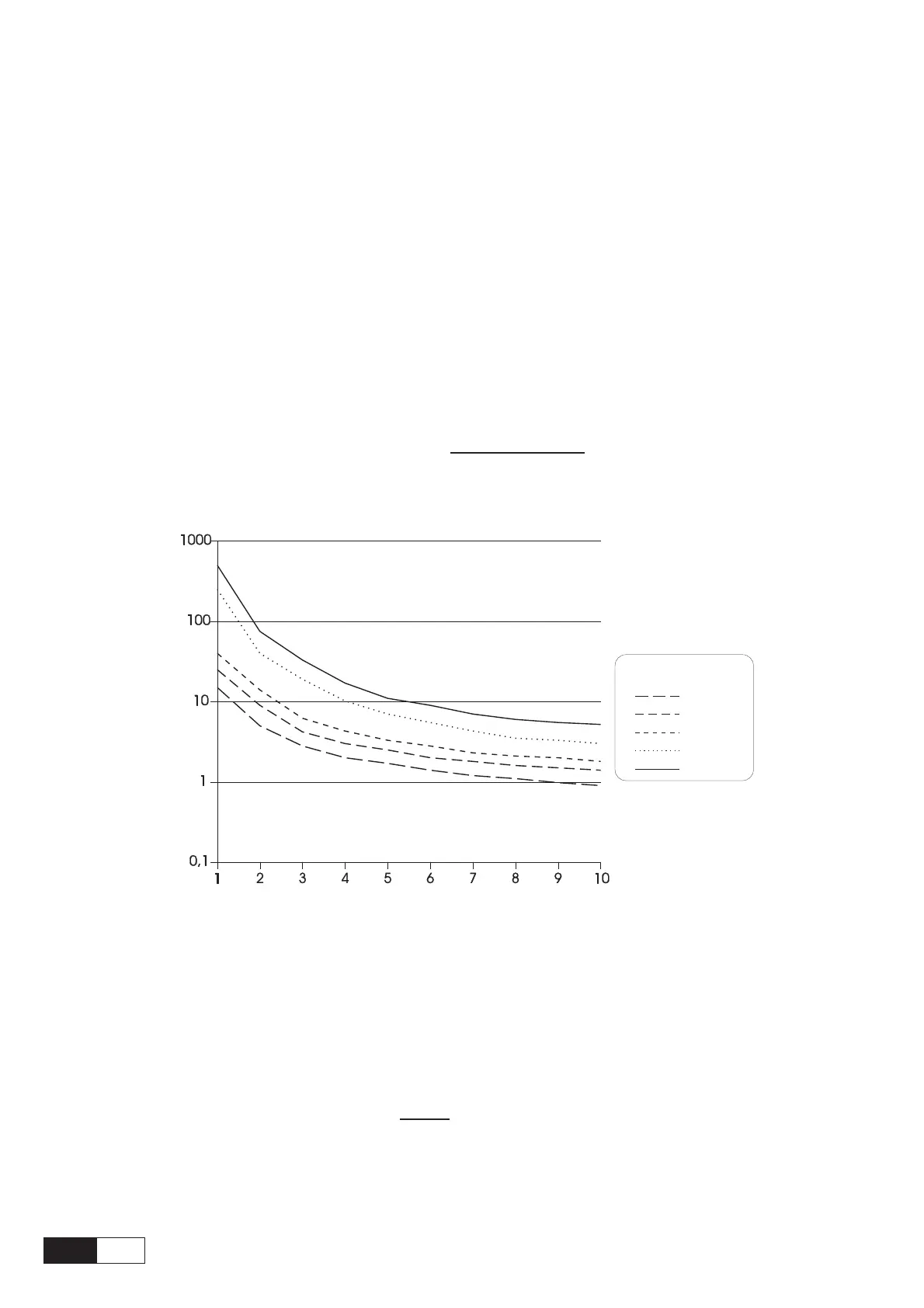

The following diagram is valid for rectangular load profile, it can be used in order to determine the overload

value. For triangular load profile, this diagram gives a safety conservative dimensioning (similar diagrams

can be provided by the manufacturer of the resistor to be used).

In order to calculate the value of the continuous power (or rated power) of the braking resistor , the overload

factor should be determined using the diagram, then the following formula must be applied:

Nominal Power P

MBR

=

fA003

Overload factor

P

MB

RESISTOR POWER

TIME OF OVERLOAD (sec. - log. scale)

OVERLOAD FACTOR

Pause Time

15 sec.

30 sec.

1 min.

5 min.

30 min.

Figure 5.8.3.1: Power Resistor Overload Factor

Example: In order to stop a 18.5 kW motor (38A at 400V) with a 150% overload, the max.

regenerated power is 27.75 kW. Assuming a 5-second braking time (overload time

for resistance) and 1-minute pause, the diagram gives a 3.9 overload factor.

Therefore, the resistor rated power will be:

PNBR

=

fA004

27750

3.9

@ 7100 W

As for types bigger than 5550 or for particular braking cycles, it is recommended to use one or more BU-32

external braking units.

Loading...

Loading...