Multiple-Axis Machining | Three-dimensional tool compensation (option 9)

13

584

HEIDENHAIN | TNC 620 | Conversational Programming User's Manual | 10/2017

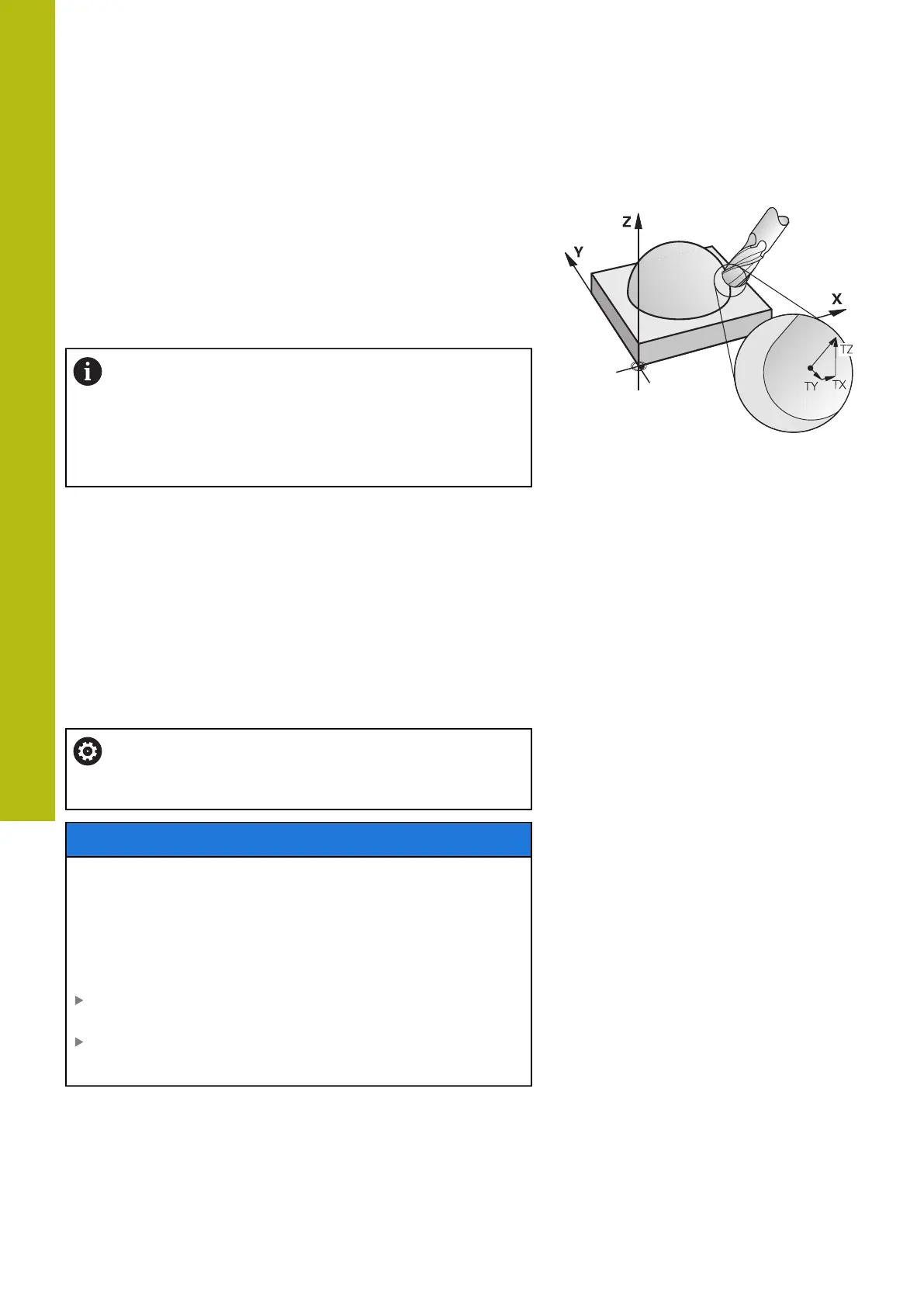

Face Milling: 3D compensation with TCPM

Face milling is a machining operation carried out with the front face

of the tool. If the NC program contains surface-normal vectors and

TCPM or M128 is active, 3-D compensation is executed with 5-axis

machining. Radius compensation RL/RR must not be active in this

case. The control displaces the tool in the direction of the surface-

normal vectors by the total of the delta values (from the tool table

and TOOL CALL).

The control generally uses the defined delta values

for 3-D tool compensation. The entire tool radius R +

DR) is only taken into account if you have activated the

FUNCTION PROG PATH IS CONTOUR function.

Further information: "Interpretation of the programmed

path", page 588

If no tool orientation was defined in the LN block and TCPM

is active, the control maintains the tool perpendicular to the

workpiece contour.

Further information: "Maintaining the position of the tool tip when

positioning with tilted axes (TCPM): M128 (option 9)", page 568

If a tool orientation T has been defined in the LN block and M128

(or FUNCTION TCPM) is active at the same time, then the control

will position the rotary axes automatically in such a way that

the tool can reach the specified tool orientation. If you have not

activated M128 (or TCPM FUNCTION), then the control ignores the

direction vector T, even if it is defined in the LN block.

Refer to your machine manual.

The control is not able to automatically position the

rotary axes on all machines.

NOTICE

Danger of collision!

The rotary axes of a machine may have limited ranges of

traverse, e.g. between -90° and +10° for the B head axis.

Changing the tilt angle to a value of more than +10° may result

in a 180° rotation of the table axis. There is a danger of collision

during the tilting movement!

Program a safe tool position before the tilting movement, if

necessary.

Carefully test the NC program or program section in the

Program run, single block operating mode

Loading...

Loading...