91

3.2.1 Zero and Span Calibration for XNX EC Sensors,

mV Sensors, and Searchpoint Optima

Caution: Beforeinitialcalibration,allowthesensortostabilizefor30minutes

afterapplyingpower.WheninZeroandSpanCalibrationmodes,thecurrent

outputfromthesensorisinhibited(default2mA)toavoidfalsealarms.

Caution:Formoststickygases(e.g.,HCl,Cl

2

)usePTFEtubingwithshort

piecesofrubbertubeforthefinalconnection(duetotheinflexibilityofPTFE).This

minimizesadhesionofthegastothetubesurfaceandallowsmoreaccurate

measurement.

Tocalibratethesensor,useanappropriatespangascylinder,

tubing,magnet,andcalibrationgasowhousing�Settheow

regulatorto300-375ml/minforXNXECsensorsor500±200ml/

minforXNXmVsensors�Acompressedgascylinder(20�9%Vol

oxygen)shouldbeusedtoperformthezerocalibrationifthe

areawherethesensorislocatedcontainsanyresidualamount

ofthetargetgas�Ifnoresidualgasispresent,backgroundair

canbeusedtoperformthezerocalibration�ContactaHoneywell

Analyticsrepresentativefordetailsaboutsuitablecalibrationkits�

Tocalibratethesensor,followtheprocedureinSection3�2�2�

Note: Theoxygensensordoesnotrequireazeroingprocedure.Background

air(20.9%Voloxygen)canbeusedtospantheoxygensensorinplaceofa

compressedaircylinder(20.9%Voloxygen).SeeSection6.3.2forothersensors.

Note: ENperformancestandardsrequire10minutesstabilizationtimefor

applicationofzeroandspangasforperformance-approvedEC,mV,andIR

sensorspriortocalibration.

3.2.2 Calibration Procedure

Thissectionoutlinesthestepsforcalibratingthetransmitter’s

attachedsensors�

Note: TheZeroCalibrationprocedureshouldbeperformedpriortotheSpan

Calibrationprocedure.

1�Ifusingacompressedgascylinder,pushthecalibration

gasowhousingontothebottomofthesensorandapply

thegas�

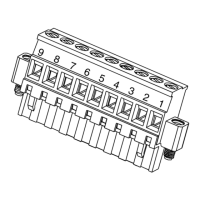

2�AccesstheGasCalibrationMenu�

Figure 194. Gas Calibration Menu

Note: TheGasCalibrationmenuisforbothZeroCalibrationandSpan

Calibration.

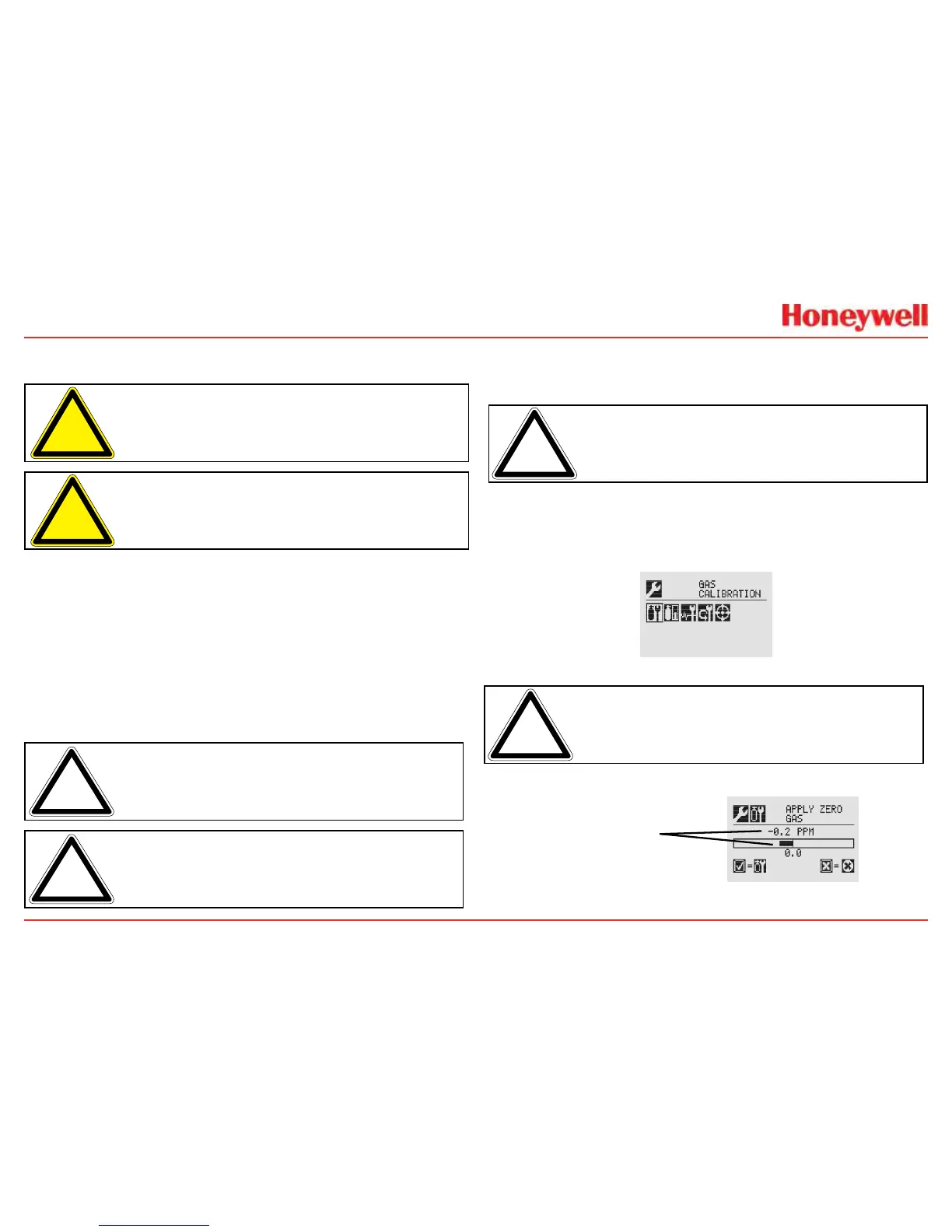

Zero Calibration

Sensor Reading

Loading...

Loading...