6 Parameter Description

-

231

-

If this parameter is set to a value smaller than 3s, it becomes invalid.

Function

Code

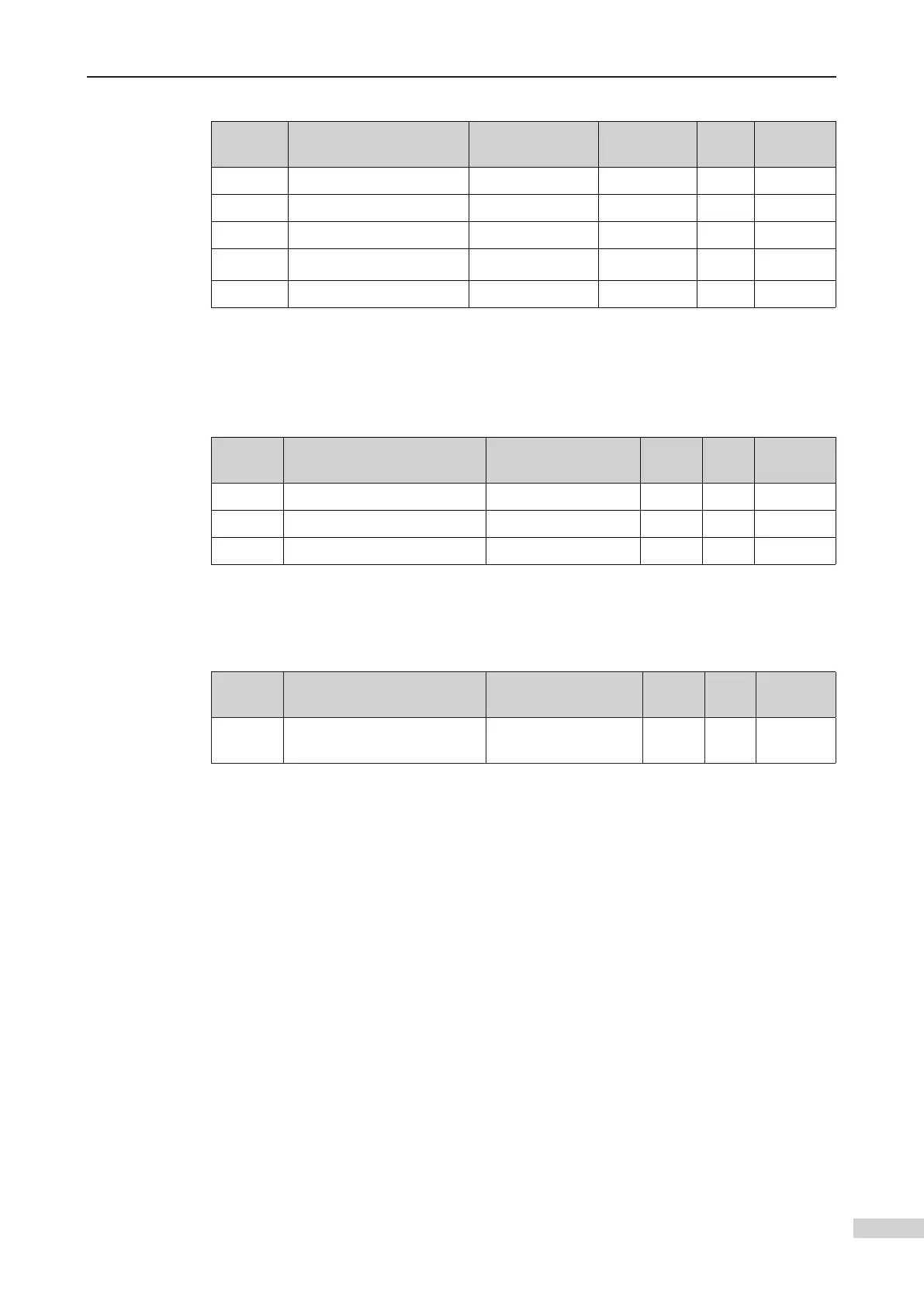

Name Setting Range Default Unit Property

F9-03 Clock: year 2000 to 2100 Current time YYYY

☆

F9-04 Clock: month 01 to 12 Current time MM

☆

F9-05 Clock: day 1 to 31 Current time DD

☆

F9-06 Clock: hour 0 to 23 Current time HH

☆

F9-07 Clock: minute 0 to 59 Current time MM

☆

These parameters are used to set the current date and time of the system.

These parameters are to control internal time of the system. Time keeping is support-

ed at power failure. You need to set the current system time correctly so that functions

related to the time can be implemented.

Function

Code

Name Setting Range Default Unit Property

F9-09 Accumulative running time 0 to 65535 0 h

F9-11 High byte of running times 0 to 9999 0 -

F9-12 Low byte or running times 0 to 9999 0 -

These parameters are used to view the actual accumulative running time and running

times of the elevator.

Running times of the elevator = F9-11 x 10000 + F9-12.

Function

Code

Name Setting Range Default Unit Property

F9-13

period

0 to 99 0 day

☆

When this parameter is set to a non-zero value, this function is enabled, and the sys-

and the counted days reaches the value of this parameter, the elevator enters the

parking state and the system reports Err08, notifying that the elevator must be main-

elevator, and then the system clears the value to 0 and starts counting again. If this

parameter is set to 0, this function is disabled.