32

7.3 Electrical connection

7.4 Gas connection

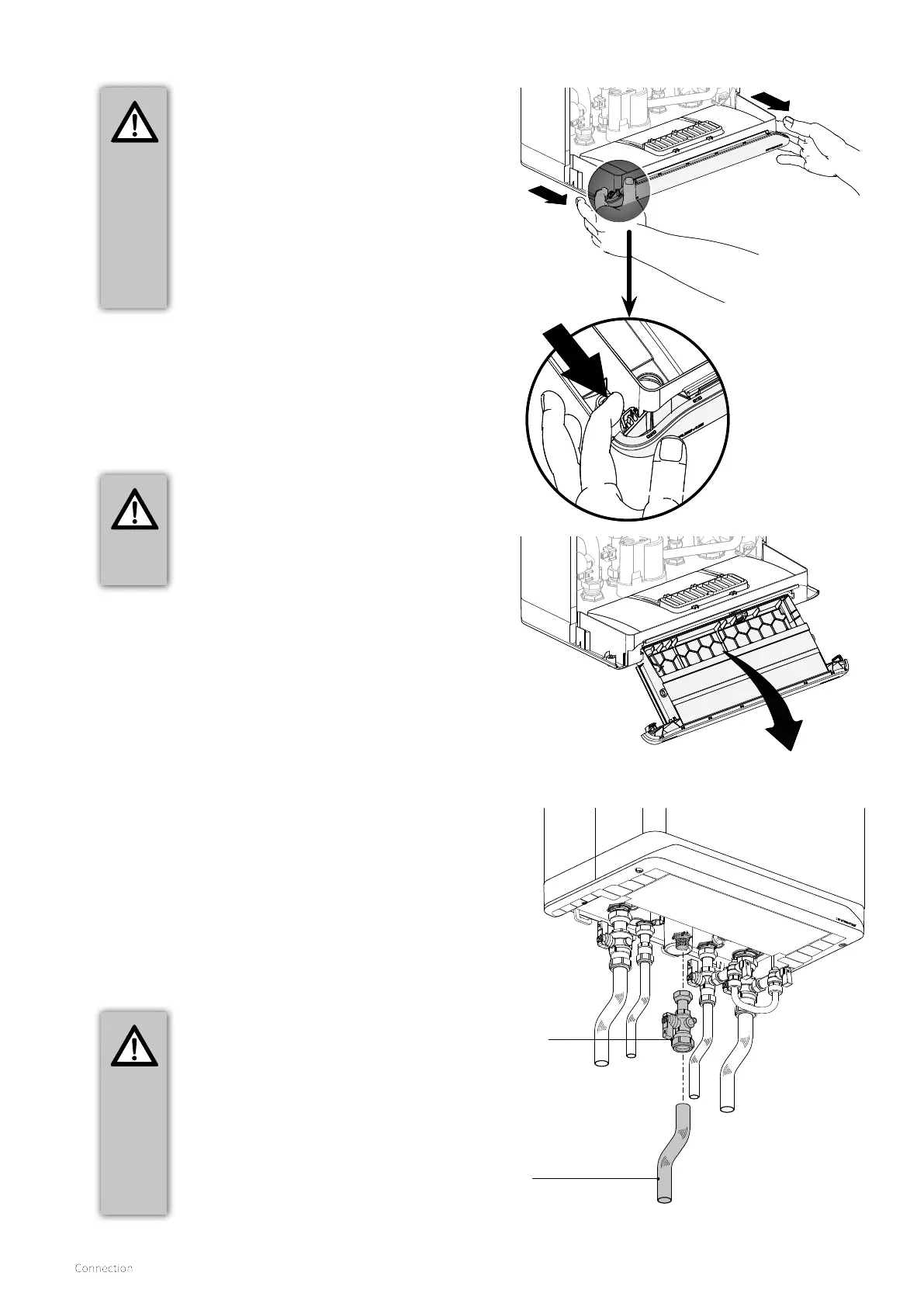

To gain access to the electrical connections or PCB:

► Remove the front panel (see §6.2.2) and pull the PCB

housing forward; then tilt it downwards.

► Consult the electrical schematic in §12.1 for all boiler

connections.

► Aer the desired connections have been made, slide the

PCB housing back into the boiler (until the le and right

safety clips are locked) then replace the front room sealed

cover on the boiler; see §6.2.2.

► Aer making the desired connections re-establish the power

supply to the boiler.

CAREFUL

► The Xclusive complies with IPX4D water

ingress protection. Any cables routed

through the PCB housing must have

grommets or glands fitted to ensure this

integrity is maintained.

CAREFUL

► A fused spur must be located no more

than 1 metre from the appliance.

► For installation within a moisture bound

area i.e a bathroom or kitchen then

please consult the current electrical

regulations for safe separation distances.

► When working on the electrical circuit

always isolate the 230v supply.

► Should the mains power cord be

replaced, this must be ordered directly

from Intergas.

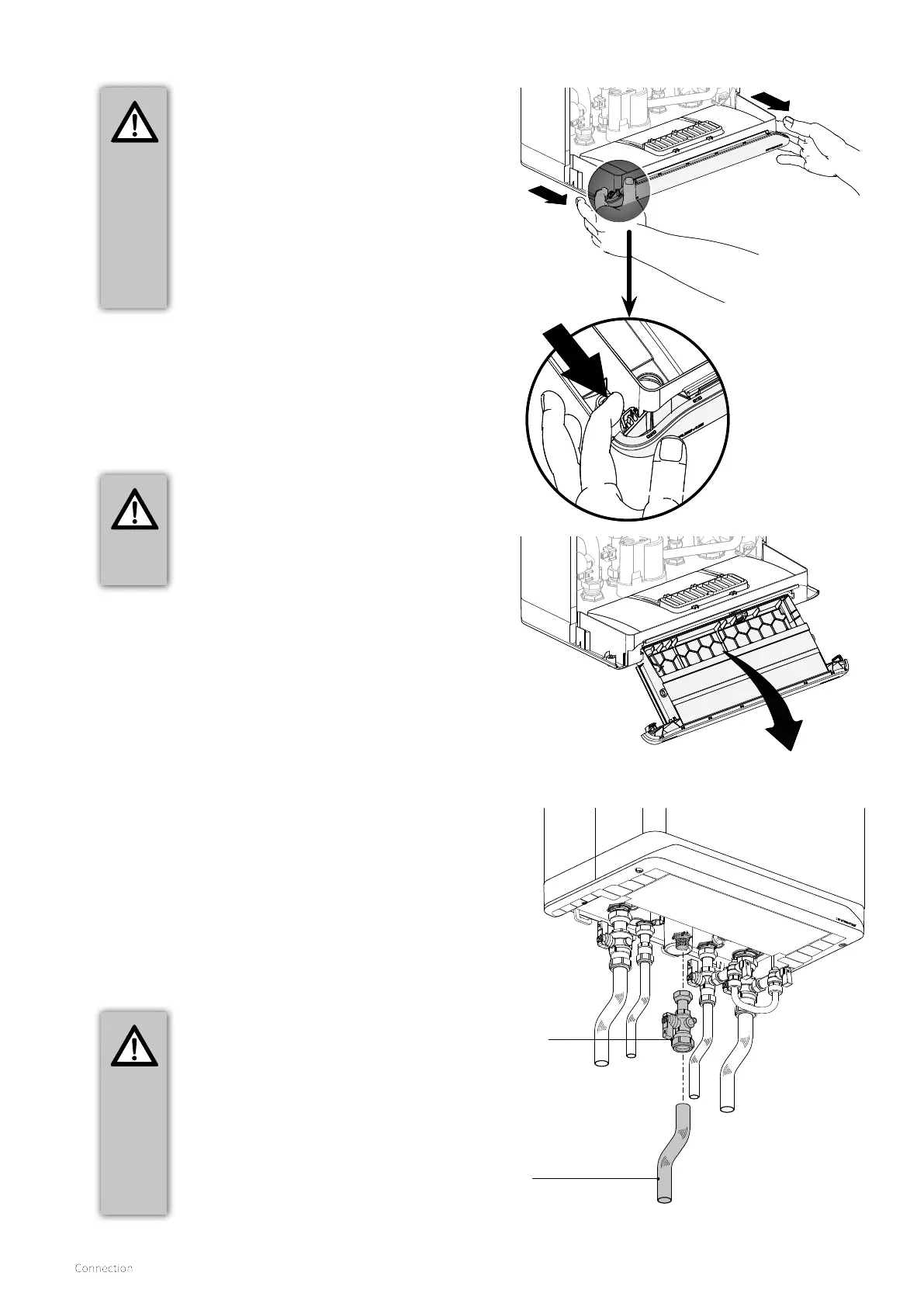

► Using the supplied gas isolation valve & fibre washer

connect the preformed gas pipe to the installation supply

pipework and fully tighten.

► Ensure that the gas pipework is correctly supported with

wrap over type clips.

► Open the main gas valve and boiler isolation valve then

purge the system of air.

► Carry out a full tightness test checking all connections for

any leakage (any leaks must be rectified before proceeding).

CAREFUL

► Before starting any work on the boiler,

always close the gas isolation valve.

► The boiler is intended exclusively to be

installed on a domestic gas supply with a

meter that includes an ECV and pressure

governor.

► When pollution in the gas is to be

expected a gas filter must be placed

in the gas installation pipework to the

boiler.

Gas isolation

valve

22 mm preformed

gas pipe

Loading...

Loading...