80

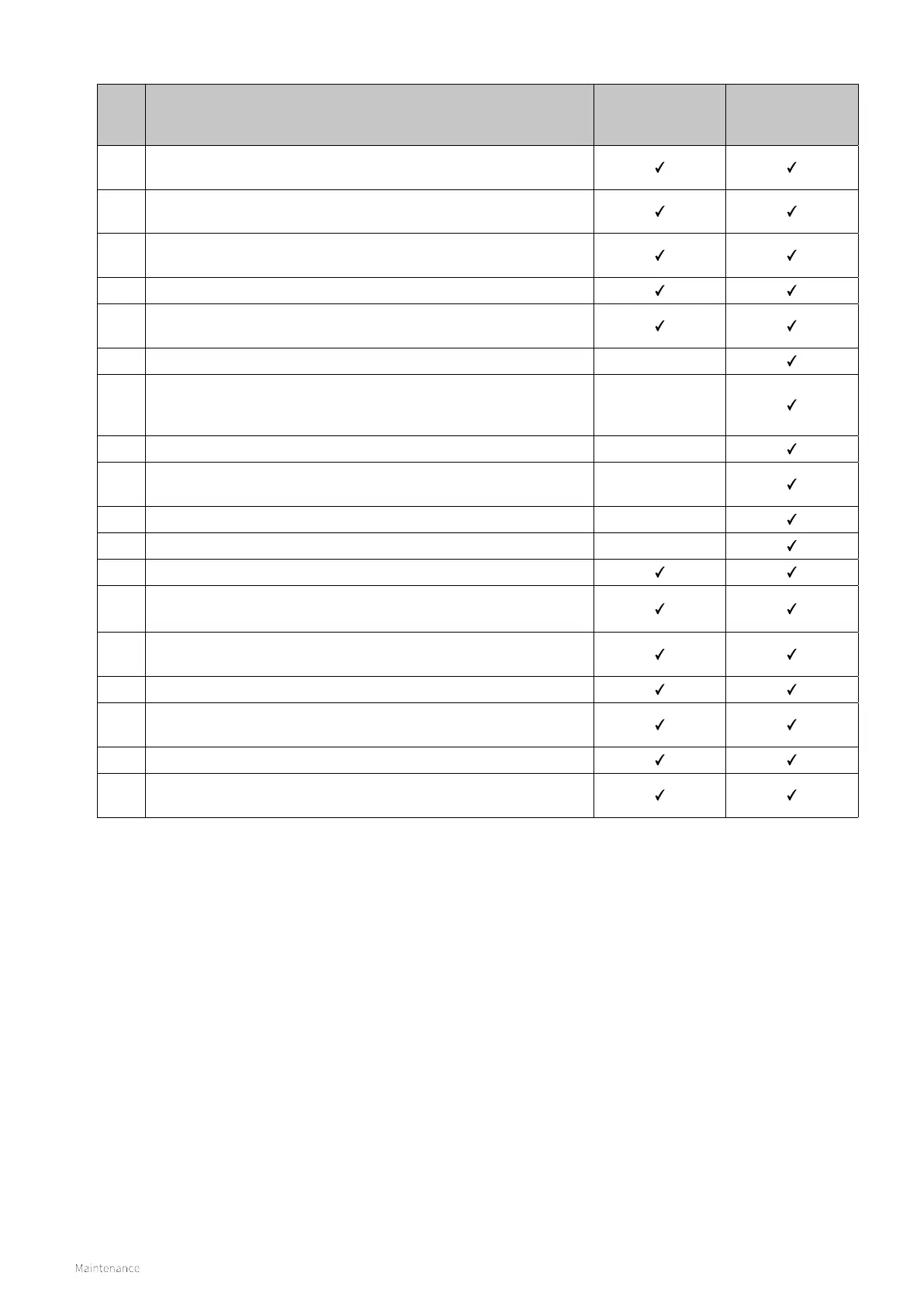

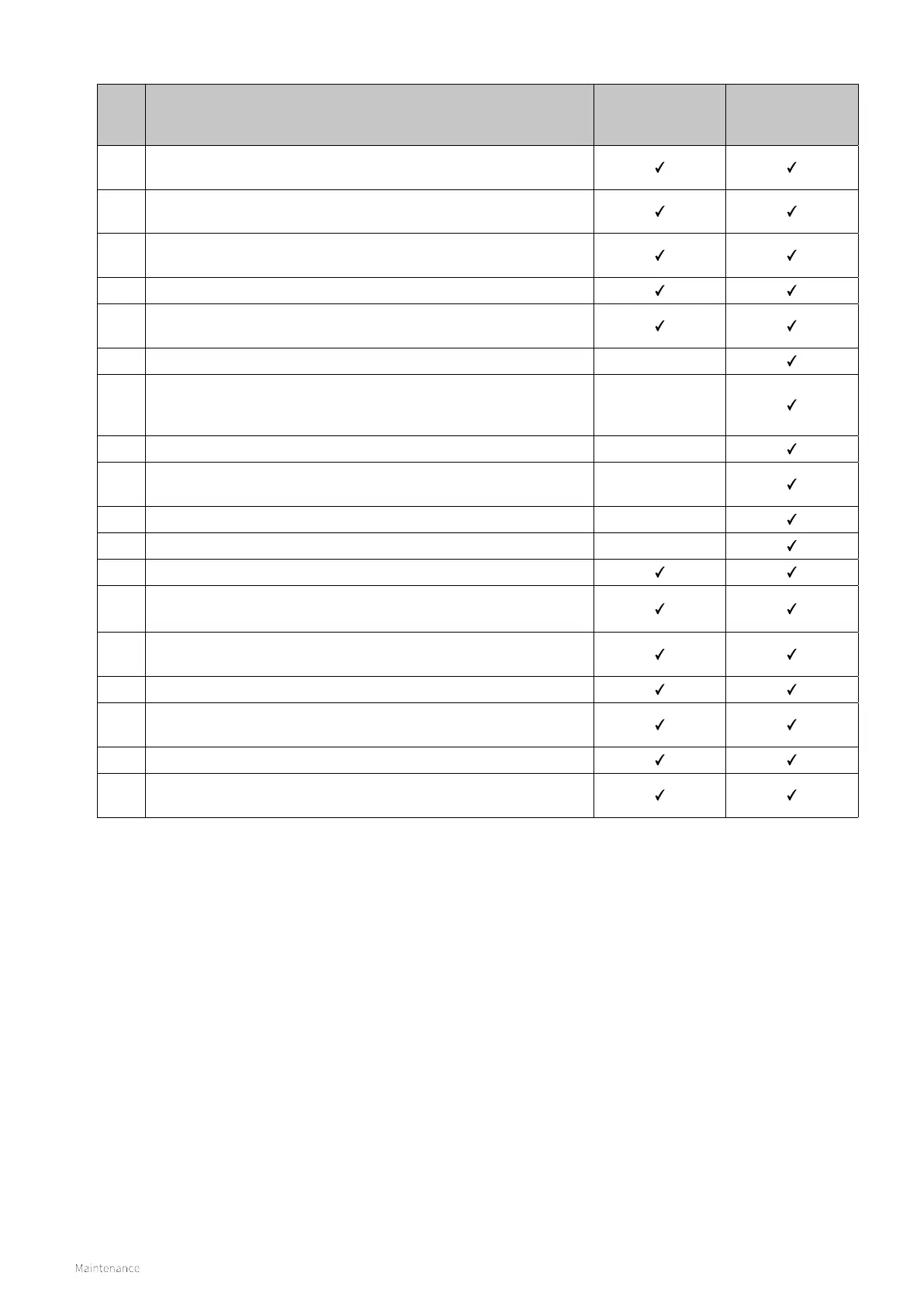

11.5 Annual service checklist

No. Activity

Inspection at

every annual

service

Maintenance

must be carried

out at regularly

1

Isolate the boiler from the fused spur and make safe (ref TB118) check

the correct 3amp fuse has been fitted.

2

Carry out inspection of boiler for dust and dirt and clean where

necessary.

3

Visually inspect the front plate and heat exchange for signs of

damage. If damage is evident proceed to column 2.

4

Check the gas inlet pressure on HIGH rate (DHW mode).

5

Check combustion by measuring CO, CO

2

. If the values are outside the

tolerances then proceed to a full service in column 2.

6

Close the boiler gas isolation valve.

7

Isolate flow and return valves and drain boiler via the drain o on

the return. Check the pressure in the expansion vessel. Recharge if

necessary.

8

Remove the front plate and clean the inside of the heat exchanger.

9

Check the front plate seal, replace the seal if damaged, discoloured,

3 years old or later.

10

Check the burner has not delaminated also check the burner seal.

11

Check the ignition pin for clearance and debris.

12

Check the condensate trap, clean and refill.

13

Open the isolation valves on flow and return and refill the water in the

boiler between 1.2 to 1.5 bar via the filling loop.

14

Open the gas isolation valve, reconnect the power to the boiler via

fused spur.

15

Check visually the ignition and burner performance.

16

Check the boiler for leaks of any kind (gas, flue gas, water,

condensate) rectify if necessary.

17

Recheck the CO,CO

2

and adjust if necessary, adjust CO

2

only LOW fire.

18

Complete the Benchmark Service Record on the back pages of the

Installation manual.

Loading...

Loading...