76

11 MAINTENANCE

11.1 Annual service procedure

11.2 Annual service continued (syphon maintenance).

The boiler and the system must be inspected annually by an qualified competent gas safe registered engineer.

The boilers heat exchanger should be cleaned and inspected as stated below at each service interval.

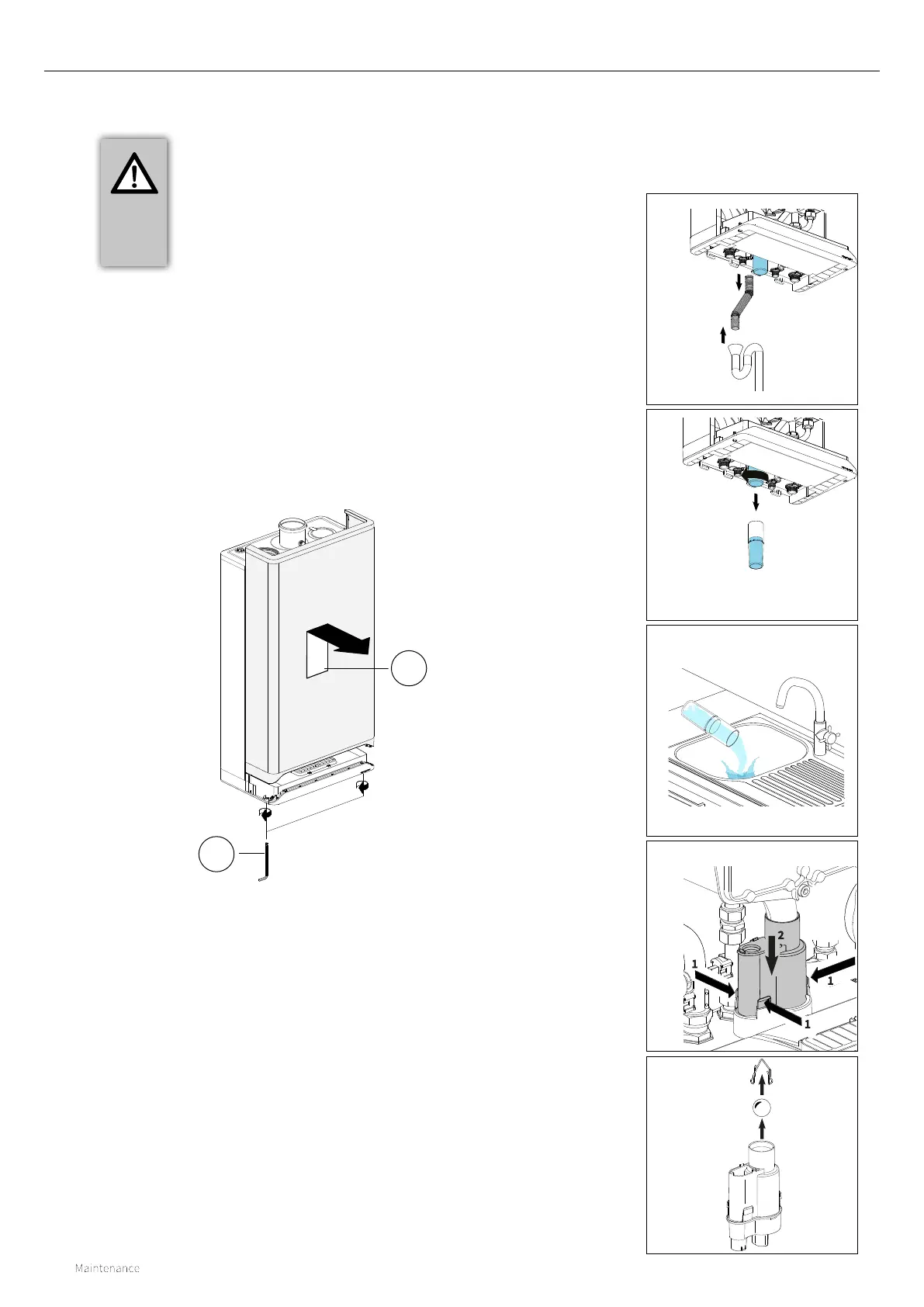

► Detach the syphon cup (1) by rotating it a quarter turn to the

le and then pulling it out downwards.

► Remove the flexible hose (2) from the siphon base and the

sewage connection.

► Empty the syphon cup (3).

► Detach the syphon base (3) by pressing the three securing

clips in, while simultaneously pushing the siphon base

downwards (4).

► Remove the circlip and the plastic ball from the syphon base

(5).

► Clean the following components with water:

◉ the inside of syphon base

◉ plastic ball

◉ circlip

◉ syphon cup

◉ opening of the exhaust manifold

2

1

1

1

1

2

3

4

5

CAREFUL

► Aer completion of the Annual service

procedure all 26 (9) safety checks must be

performed and the results recorded within

the service & interim boiler work pages, at

the back of this manual.

► Some components can be very hot during and

just aer operating the appliance.

► For Health & Safety reasons the use of PPE is

recommended during the below procedure.

► Switch o the appliance and isolate the power supply at the fuse

spur, make safe the appliance before continuing (Ref TB118).

► Close the boiler gas isolation valve (test for let-by).

► Remove the room sealed cover of the boiler by loosening the two

Allen screws (A) and then liing the panel up and forward (B)

► Wait until the boiler has cooled down. This can be done by

opening a domestic hot water tap (with the power switched o).

A

B

Loading...

Loading...