67

A. Switch o the boiler (see §8.2.1).

A dash

–– will appear on the right display and the central heating

pressure will be visible on the le display.

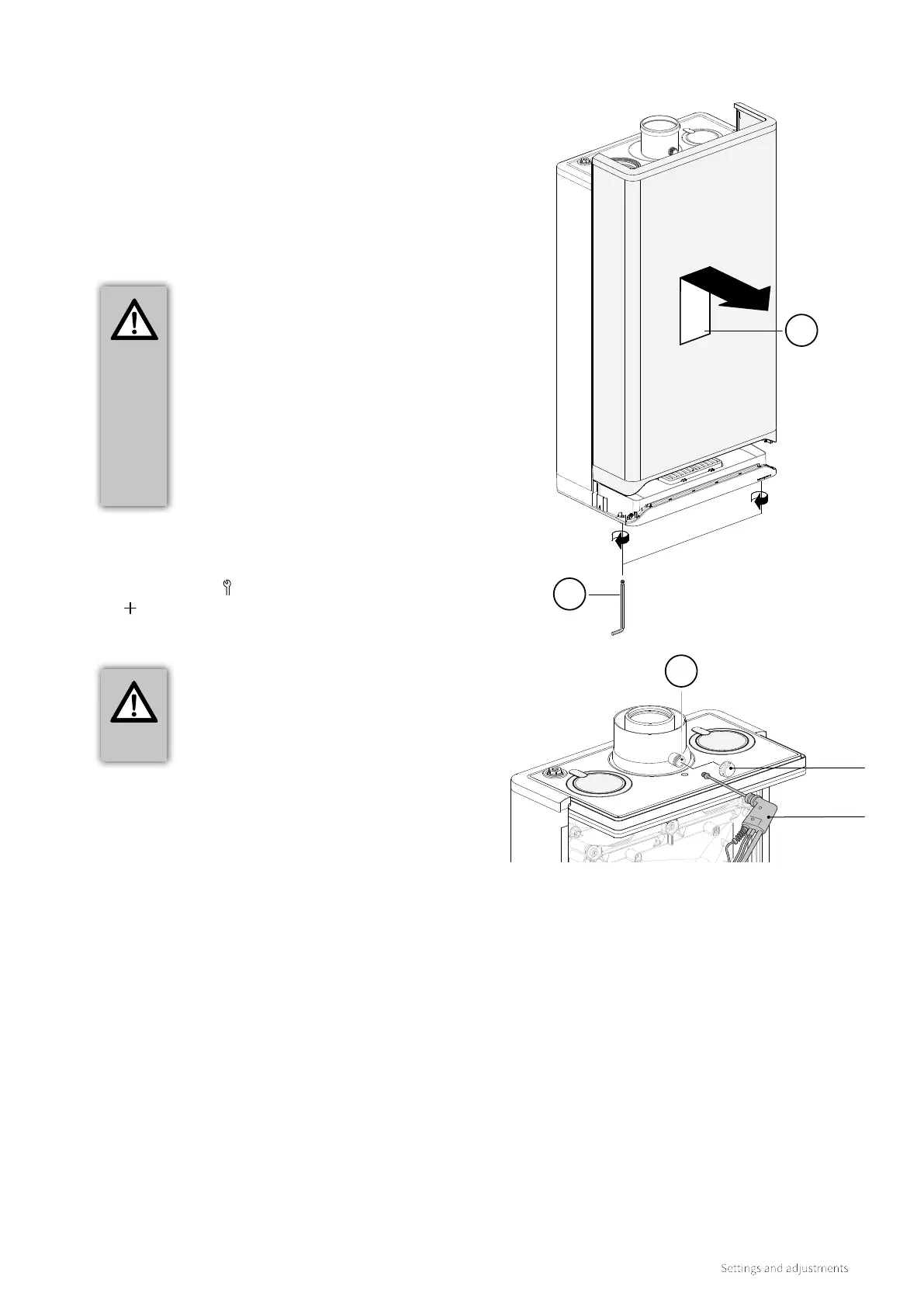

B. Remove the room sealed cover of the boiler by loosening the 2x

5mm Allen key screws (1) and then sliding it up and forward (2).

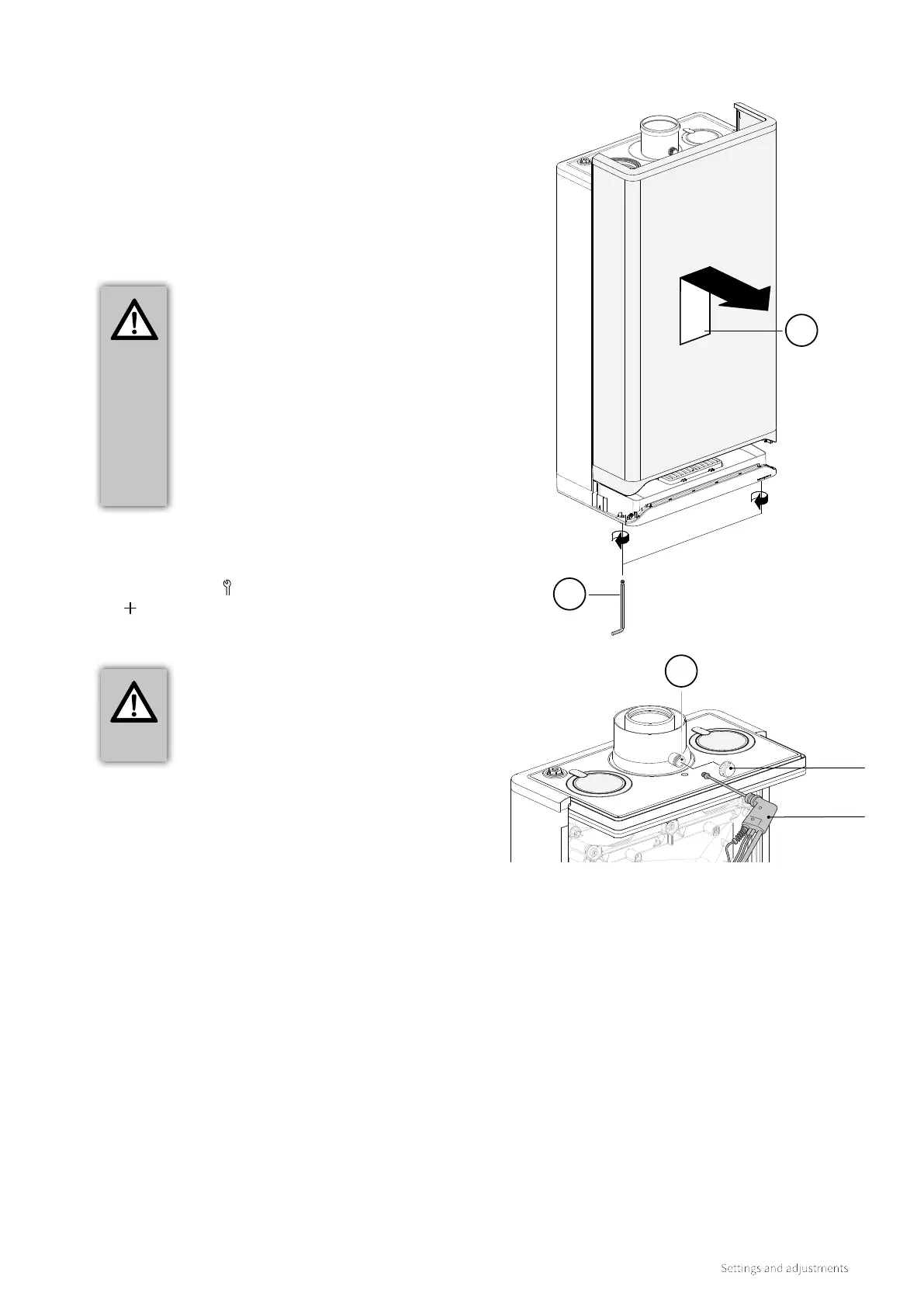

C. Remove the cap of the flue gas sampling test point (3) on the

appliance connector on top of the boiler.

D. Place the sampling probe of the calibrated electronic flue gas

analyser into the flue gas sampling point (3).

IMPORTANT

► Make sure that the flue gas analyser is

calibrated. The start-up procedure of

the flue gas analyser must be completed

before the analyser probe is placed in the

flue gas measurement point.

► The analyser probe must completely seal

o the flue gas measurement point to

provide a reliable measurement.

► The end of the analyser probe must be

located entirely in the flue gases (middle

of the flue gas pipe).

IMPORTANT

► Make sure that the capital letter HH

appears on the right display. This

provides assurance that the boiler is

operating as maximum load.

E. Switch on the boiler by touching above the power light for 2

seconds.

F. Switch on the boiler to maximum output. To do this, hold the

Service symbol and at the same time tap the Plus symbol

twice until the capital letter HH appears on the right display.

G. Wait until the readout of the flue gas analyser is stable (at

least 10 minutes).

H. Note the measured CO

2

(H) value.

CO

2

(H) = measured maximum output CO

2

value

I. Check according to Table 2 whether the measured

maximum output CO

2

(H) % is between the indicated upper

and lower limits.

9.10 Inspection of the gas air control valve

9.10.1 Measuring the flue gas at maximum output

1

2

Cap

Flue gas

analyser

3

Loading...

Loading...