71

10 FAULTS

10.1 Fault codes

The following fault codes can be established:

IMPORTANT

► Using the fault code table below to

establish the cause of the issue before

attempting to reset the boiler.

NOTE: A reset is not possible when a

component is outside its tolerance

values.

Viewing fault codes

Resetting the boiler

If the boilers PCB detects a fault, this is indicated by a

flashing service symbol

on the display. A fault code, such

as F004F004, is illuminated on the le display.

The service symbol remains flashing until the boiler has

reset or where required the faulty component has been

replaced.

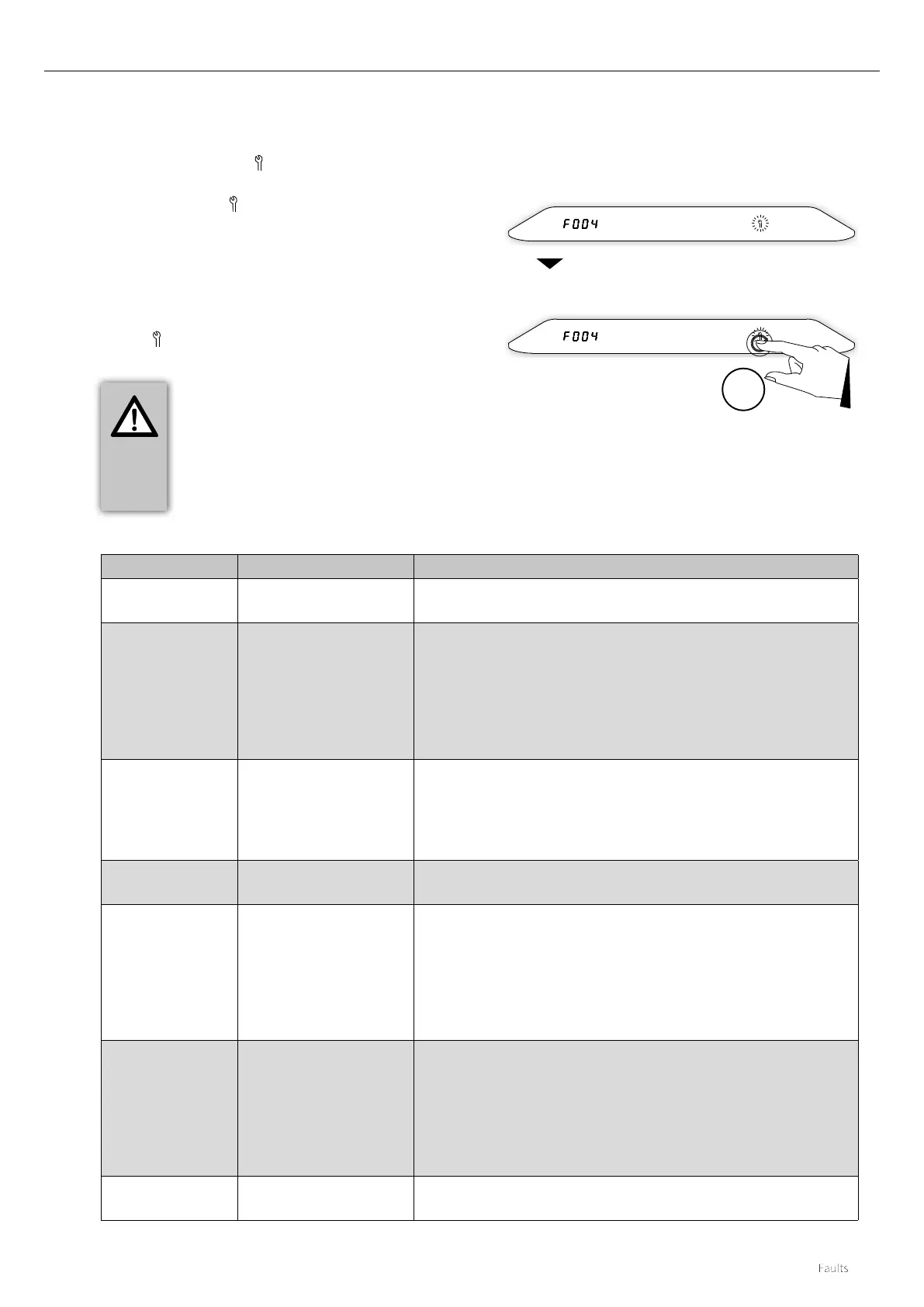

Reset

2sec

Fault code illuminated

The boiler can be reset by touching the flashing Service

button and holding it for 2 seconds. If the fault code

reoccurs an Intergas trained engineer should be requested.

Fault code Description Possible cause / solution

F000F000

Sensor S0 is defective. ► Replace heat exchanger sensor S0.

F001F001

Temperature is too high

during central heating

demand.

► Vent the heating system & boiler heat exchanger (see §8.2.1).

► Pump does not operate (check power, impellor, replace pump.

► Check wiring to the CH flow sensor S1 (ensure its connected and

not damaged).

► Check the CH flow sensor S1 (is located and installed correctly)

► Check for the correct operation of CH flow sensor S1.

► Replace central heating flow sensor S1.

F002F002

Temperature too high

during DHW demand.

► Check wiring to the DHW sensor S3 (ensure its connected and not

damaged).

► Check the DHW sensor S3 (is located and installed correctly).

► Check for the correct operation of DHW sensor S3.

► Replace domestic hot water sensor S3.

F003F003

Flue gas temperature is

too high.

► Check heat exchanger for contamination or debris.

► Check the flue / chimney for blockages.

F004F004

No flame during start-up.

► Gas valve is faulty or no power from PCB (24v dc pins 1 & 5).

► Gas inlet working pressure below 17mbar (20mbar

recommended).

► Condensation drain is blocked or frozen.

► Check ignition module, ignition pin, lead or spark gap.

► No power to Ignition unit.

► Poor earth to boiler or ionisation pin.

F005F005

Flame failure during

normal operation.

► Condensation drain is blocked or frozen.

► Gas inlet working pressure below 17mbar (20 mbar

recommended).

► Check ignition module, ignition pin, lead or spark gap.

► Check adjustment of gas valve (See §9.10.1).

► Check the flue integrity for possible re-circulation or blockages

► Poor earth to boiler or ionisation pin.

F006F006

Flame simulation.

► Replace faulty gas valve.

► Replace faulty PCB.

Loading...

Loading...