37

7.7 Pipeline lengths

7.7.1 Replacement lengths

7.7.2 Example calculation

D

D

R

R

R/D = 0,5

R/D = 0,5

Elbow of 90°

R/D=0.5 4 m

Elbow of 45°

R/D=0.5 2 m

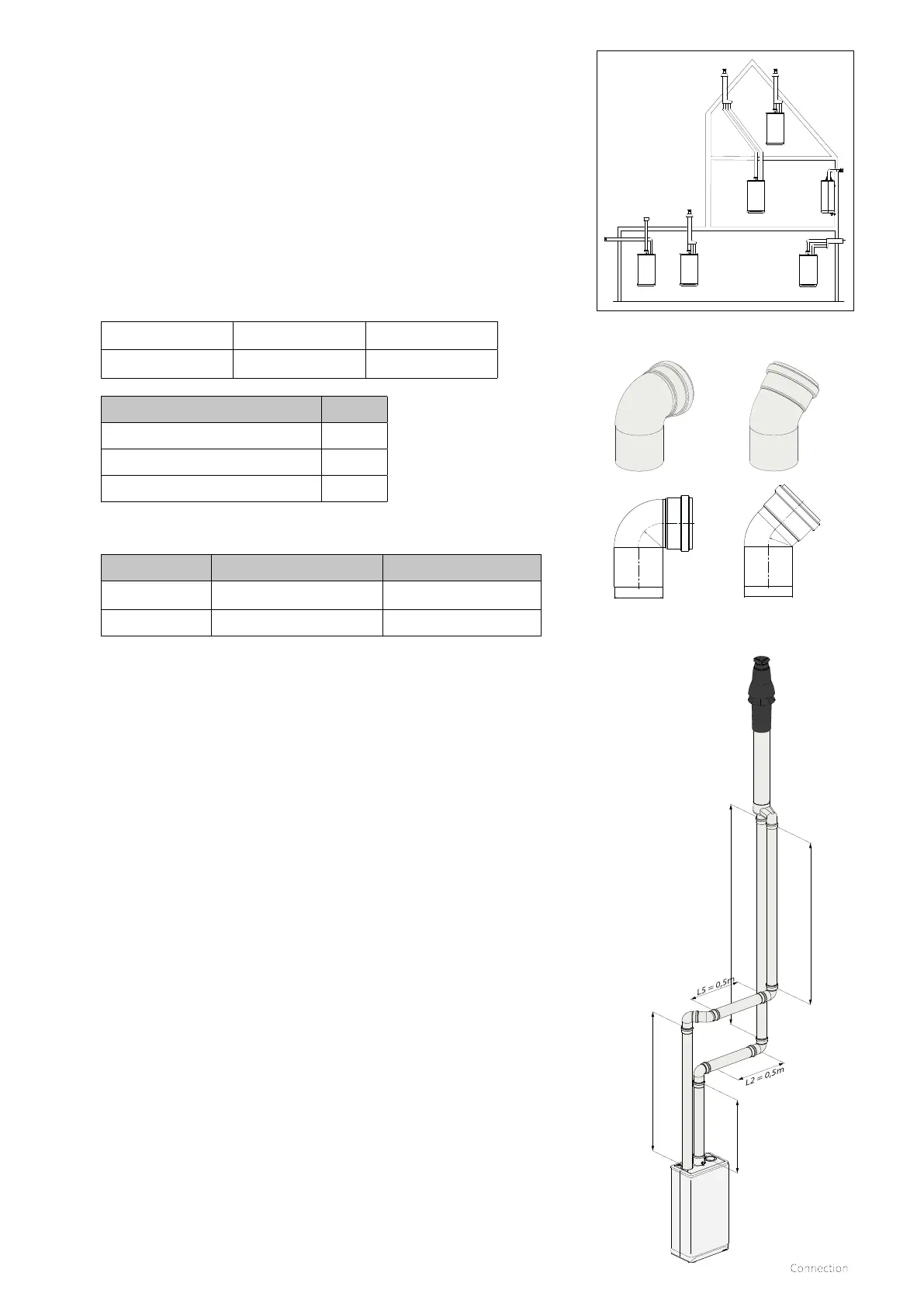

C13

C33C53

C33

C13C33

C33

C33 C13

C13C33C53

Boiler Length

Intergas Xclusive 24 100 m

Intergas Xclusive 30 85 m

Intergas Xclusive 36 80 m

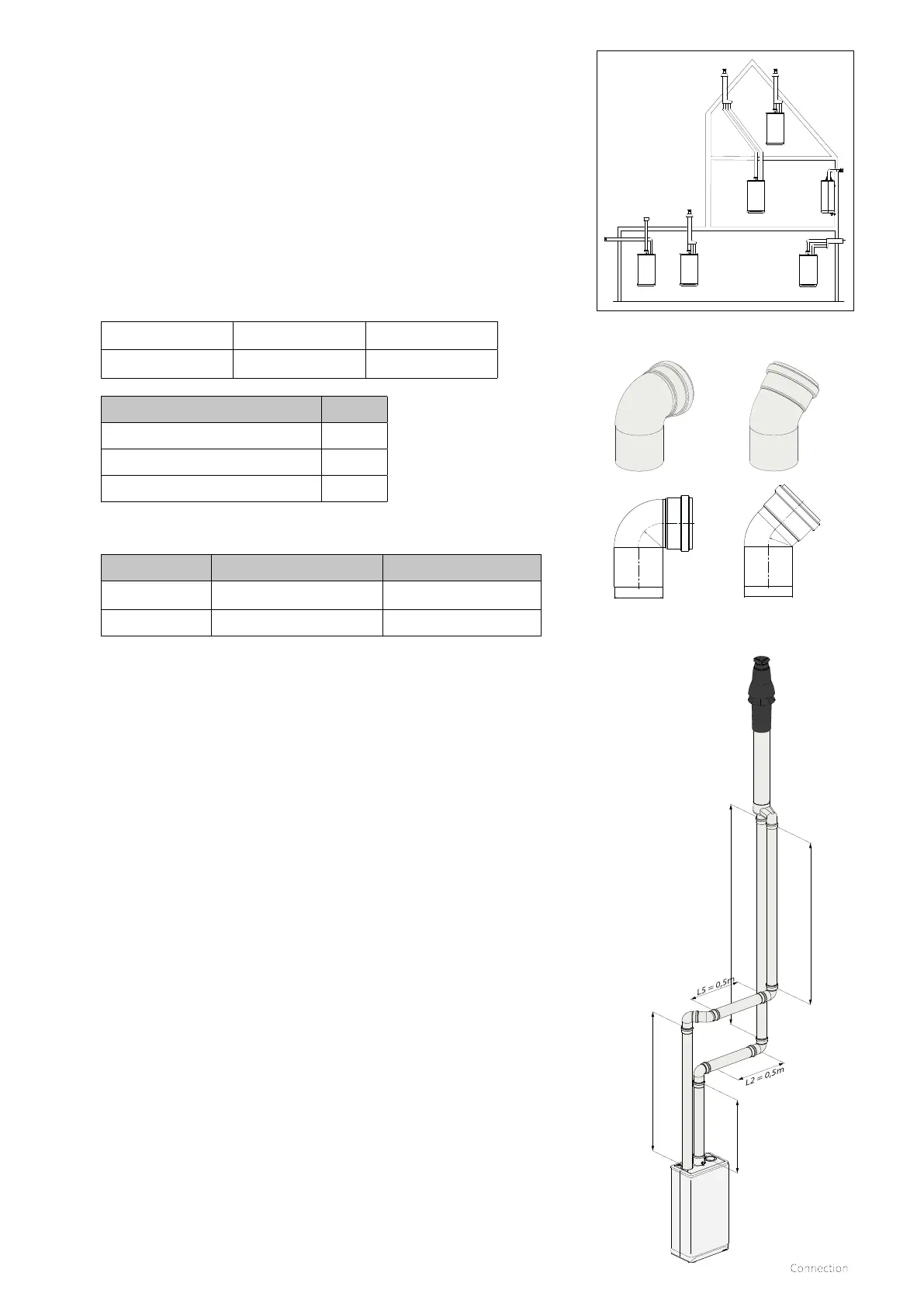

Piping Pipeline length Total pipeline length

Flue L1+L2+L3+(2x4m)

16 m

Air supply duct L4+L5+L6+(2x4m) 16 m

Comments

► The total pipeline length is:

The sum of the straight pipeline lengths + the sum of all the bends

which equates to a total of 33 metres as per the adjacent drawing.

► If the equivalent length of the air supply duct and flue gas duct

combined are less than the maximum permissible quoted then the

twin flue system meets the requirements at this point.

Twin Flue General assembly guide

Flue gas section assembly

► Connect the 80mm vertical adaptor 090767 to the boiler (optional

extra).

► Slide the combustion outlet pipe into the adaptor on the boiler.

► Working from the boiler, slide each extension spigot into the previous

socket and continue with each extension or bend.

► The flue must be bracketed every metre and every change in direction.

► Each bend should have a bracket fitted either side.

► Connect the final section to the chosen terminal outlet.

► The flue gas section must be installed with a fall of 5mm/mtr back

towards the boiler.

Air supply section assembly

► Remove either of the air induction caps by liing the tab and rotating it

anticlockwise by 90 °.

► Slide the first air inlet pipe section into the boiler induction socket.

► Working from the boiler, lide each extension spigot into the previous

socket and continue with each extension and bend.

► The air duct must be bracketed every metre and every change of

direction.

► Each bend should have a bracket fitted either side.

► Connect the final section to the chosen terminal outlet.

► The air supply section must be installed with a fall away from the boiler.

(*Not applicable to vertical flue/air sections)

L6 = 1,5m

L1 = 1m

L4 = 6m

L3 = 6,5m

As the resistance of the flue and air supply duct pipes increases, the

capacity of the boiler will decrease. The allowed decrease in capacity

is a maximum of 5%.

The resistance of the air supply duct and the flue depends on

the length and diameter of the piping system and all associated

components. For each boiler category, the total allowed pipeline

length of the air supply duct and flue is given.

The specification of the pipeline length in metres assumes Ø80

mm piping.

Loading...

Loading...