FX-3R Maintenance Guide

2-9

2-2-2. Replacing the θ-Motor

After the θ-motor has been replaced, it is absolutely necessary to re-input the MS parameters

related to the axis home. (For details of input items, see section 2-7.)

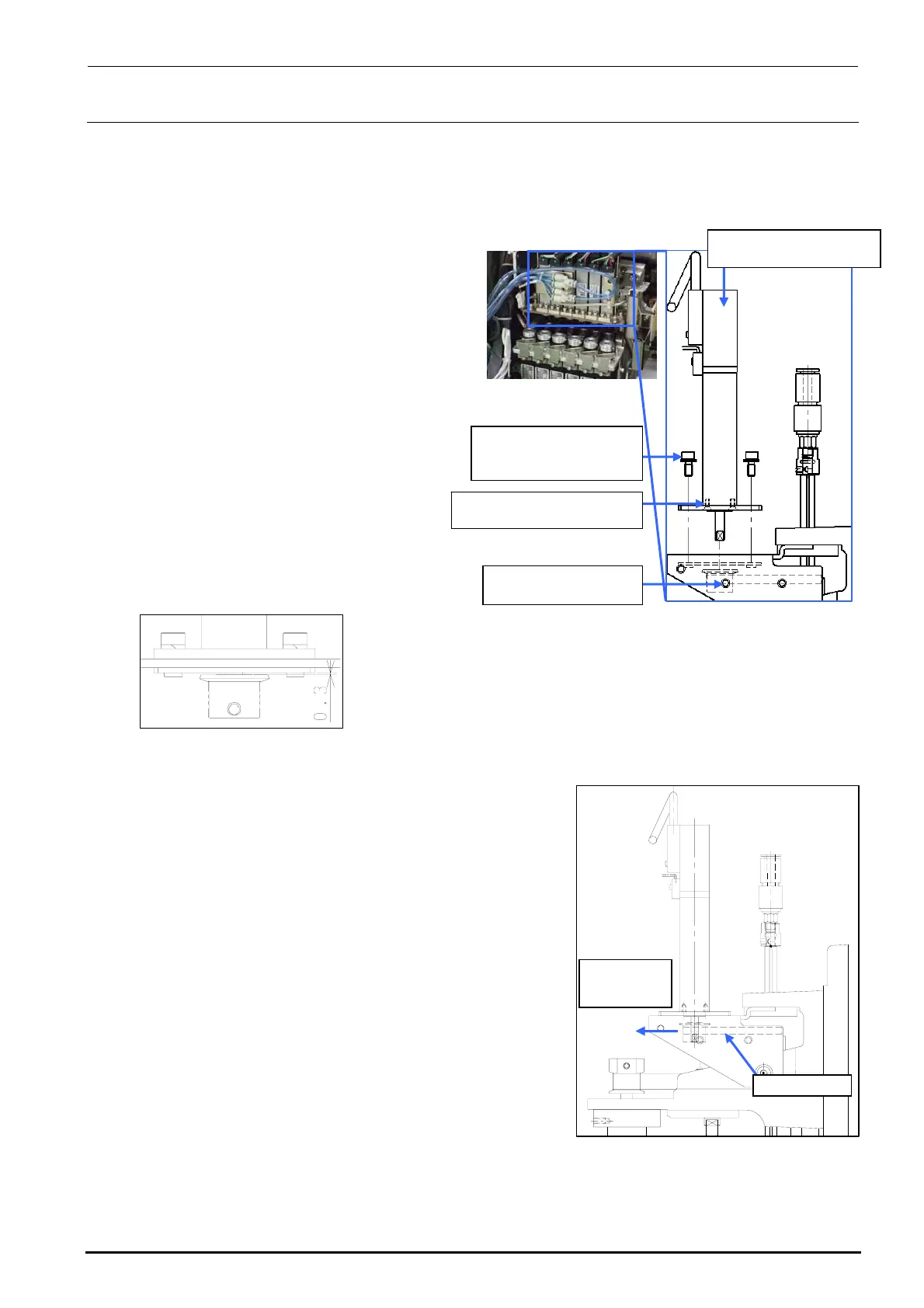

1) Disconnect the motor cables from the

servo amplifier board.

(See also steps 2), 3), 8), 9), and 10)

stated in section 2-1.)

Rev. 1.00

2) Loosen the set screws c (hollow set

screws (×1)) of the T pulley.

3) Remove the motor mounting screws d

(SEMS cap bolts (×4)) and pull out the

pulley to detach it.

4) Remove the flat head screws e (×2)

and detach the TM flange.

5) Reassemble the components in the

reverse order of disassembly.

∗ Apply Loctite 242 to the flat head

screws e and tighten them with a

tightening torque of 0.14 N・m.

c SM8030312TP

Set screw M3 L=3

40044533

Servomotor 10W (θ-axis)

SM1020501SC

Flat head screws M2 L=5

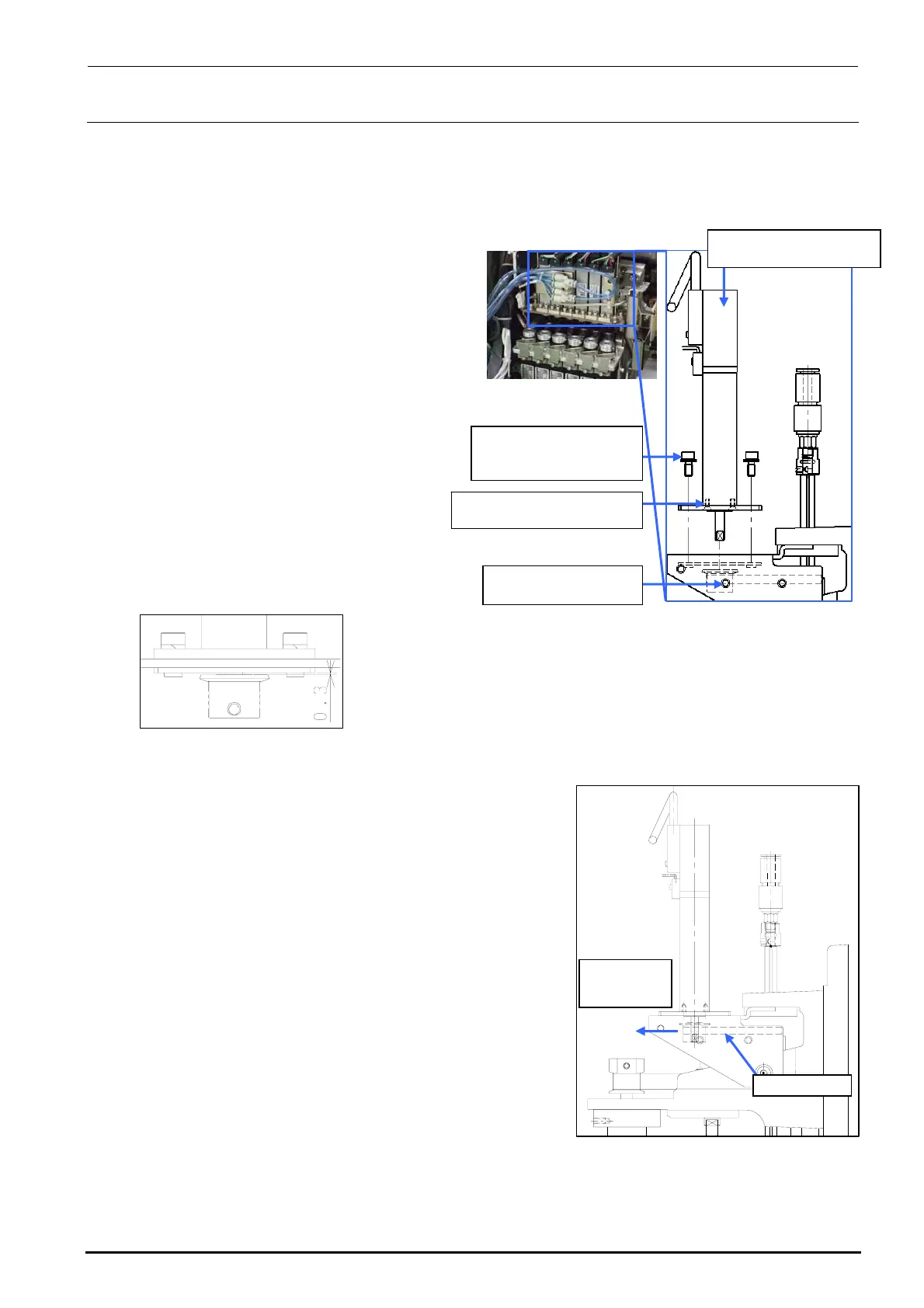

6) Follow the steps below to adjust the belt

tension.

<Belt tension adjustment procedure>

c Make a ring using a tie-up band or belt at the top end

of the T pulley of the θ-motor. Hang the bar tension on

this ring. With the bar tension kept pulled with a force

of 12.7N (1.3kgf), secure the T pulley using the

mounting screws.

Tension meter set value (For check)

• Tension meter input value

Weight: 0.9g/m Width: 4.0mm Span: 38.2mm

• Specification value: 6.5±1N

∗ Apply Loctite 242 to the θ-motor mounting screws (2

pcs.) and tighten them with a tightening torque of 2.3

N・m.

∗ When tightening the setscrew of the T pulley, make

sure to align the orientation of the flat part of the

θ-motor shaft and the setscrew of the pulley. Tighten

the setscrew with a torque of 0.5 N・m.

Timing belt T

Pull by the

force of 12.7N

(1.3kgf)

Figure 2-2-2-2 Adjustment of

the θ-motor Belt

Tension

Assemble so that the clearance

between the T pulley and TM nut

plate is 0.3 mm.

d SL6030842TN

SEMS cap bolt with

washer M3×8

Figure 2-2-2-1 θ-motor

e

Loading...

Loading...