5-2

Repair manual KTM LC8 Art.-No. 3.206.035-E

1

1

A

A

1

1

A

2

3

4

5

6

7

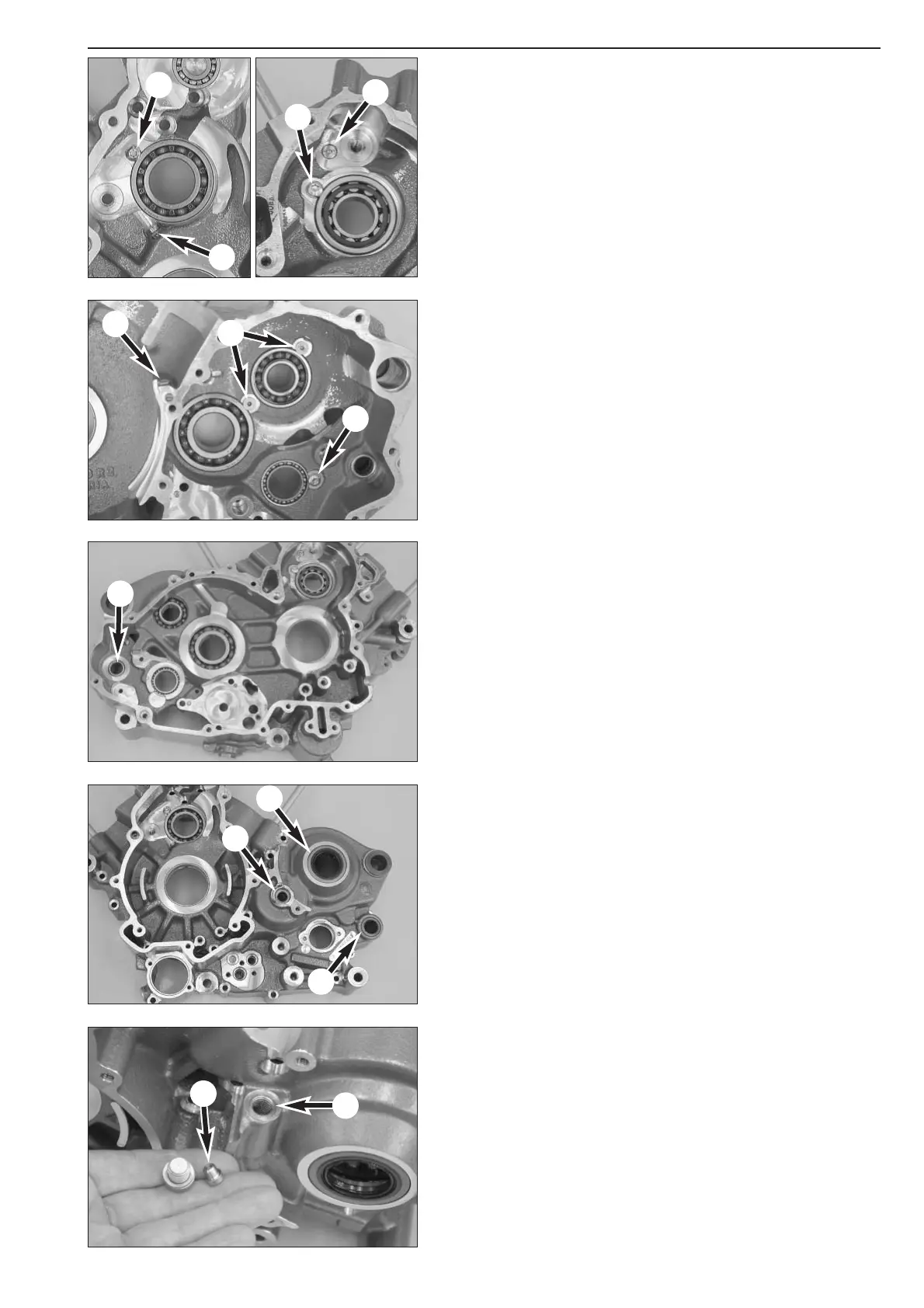

Replacing the roller bearing

– Remove all bearing locking bolts 1 from both case halves.

NOTE:

– Additional oil jets are installed from the 2005 model; they should

also be removed to prevent them from being bent.

– the output-end antifriction bearing on the countershaft mounted by

KTM does not have a sealing from the 2005 model. An antifriction

bearing with a one-sided sealing is provided for repair; to keep it

from blocking the lubrication, the open side must point towards the

inside (towards the center of the housing).

– Remove all shaft seal rings and the dowel pins from the case halves.

Heat both case halves evenly in an oven at 150° C; the roller bearings

will fall out of the case by themselves. If any roller bearings should be

left in the case, tap the case lightly on a flat wooden surface.

NOTE: the shift shaft bearing

2 must be pressed out with the pressing

tool 600.29.043.030, although this bearing is usually highly resistant

to wear.

– Replace all of the roller bearings. The new roller bearings can be

inserted by hand until flush as soon as the case temperature has

reached approx. 150° C. The roller bearings should fit tightly after

cooling down. Use a mandrel to carefully press in any bearings that

are not flush with the surface.

NOTE: the shift shaft bearing

2 must be pressed in flush with the

pressing tool 600.29.043.030.

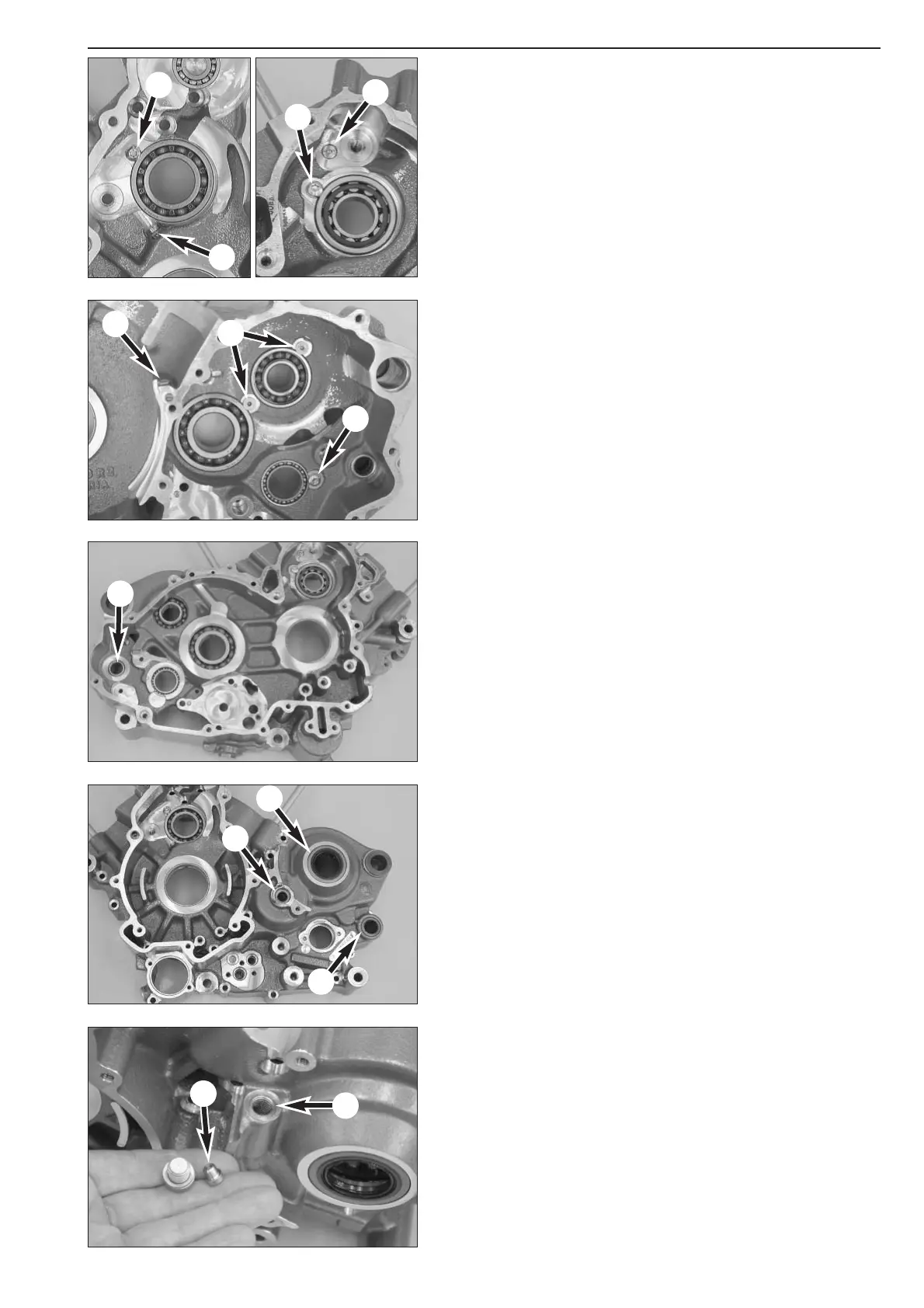

– Press in the shaft sealing ring

3 for the push rod until flush using

the special tool 600.29.043.010.

– Press in the shaft sealing ring for the countershaft

4 until flush

using the special tool 600.29.043.020.

– Press in the shaft sealing ring for the shift shaft

5 until flush using

the special tool 600.29.043.030.

–

Apply Loctite 243 to all bearing locking bolts 1 and tighten to 6 Nm.

– Remove all of the oil jets, blow compressed air through the oil ducts

and screw the oil jets back on.

NOTE:

– Size "60" jets are used to lubricate the timing chains, size "90" jets

for the piston cooling.

– Starting with engine number 2-600-02549, a size "30" reducing

sleeve

6 is screwed into the outer bore 7 on the outside of the left

housing half to supply the clutch and the pushrod with oil. This jet

should be retrofitted in all engines of an earlier make - see Technical

Information, Chapter 1.

Loading...

Loading...