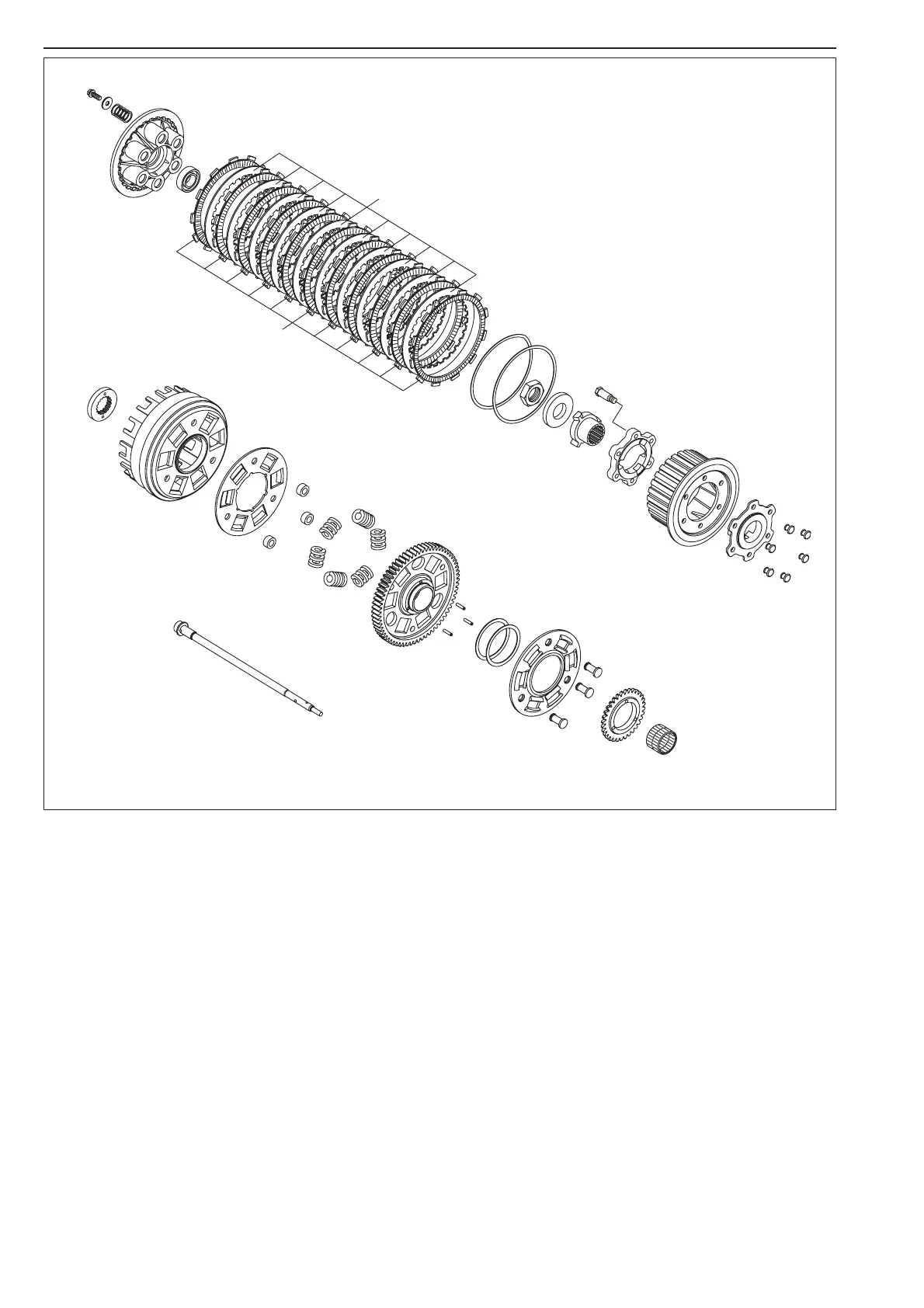

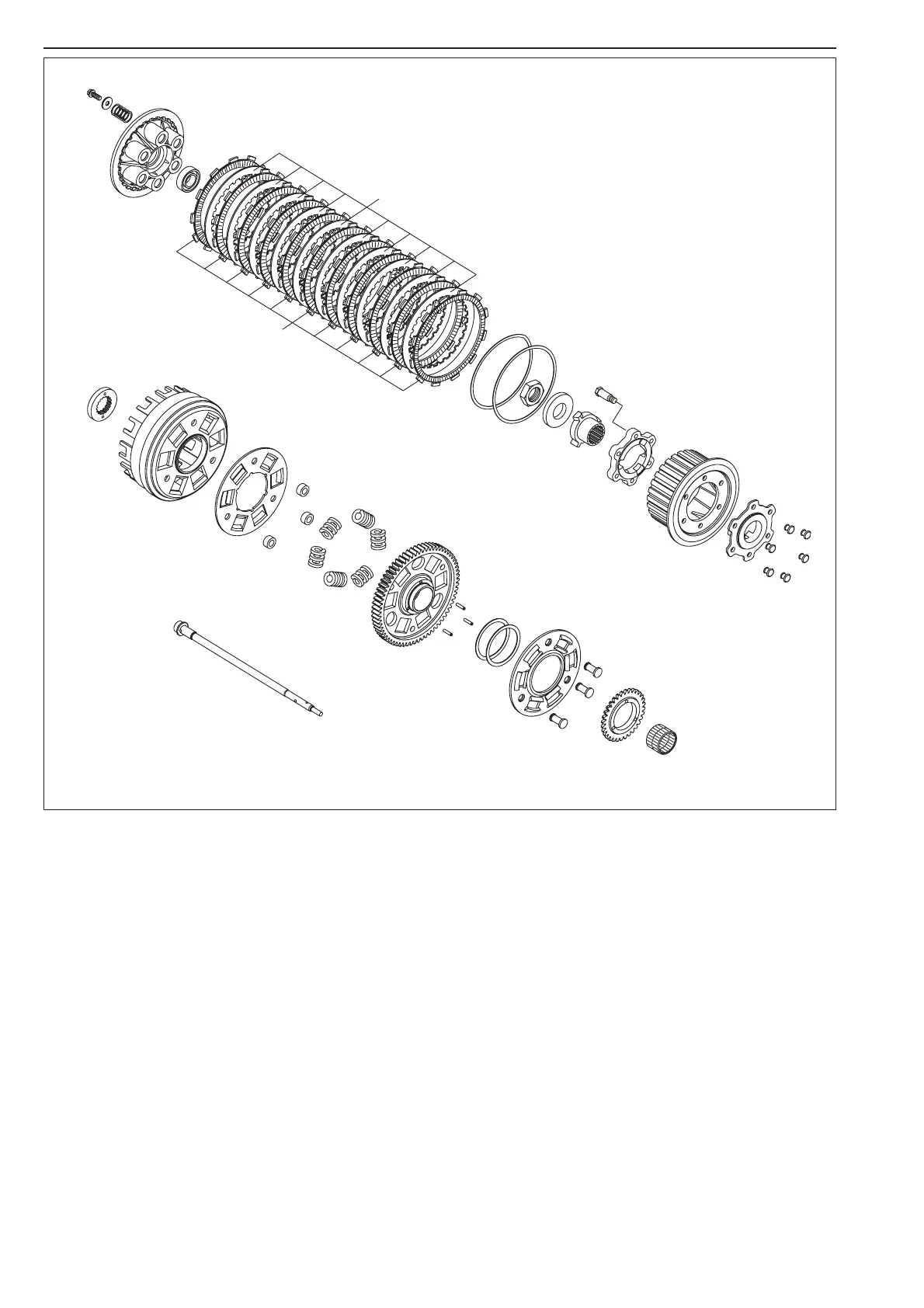

5-15

1

2

3

7

8

9

5

4

6

Clutch – checking parts for wear

Check the thrust bearing 1 for wear.

Check the front end of the pushrod

2 for wear and blow compressed air through the holes.

NOTE: the pushrod is made of nitride steel from the 2005 model. If you are repairing an engine older than the 2004 model,

replace the old pushrod with the newer version.

Clutch springs

3 must have a minimum length of 29.0 mm (new 30.77 mm). If necessary, replace all 6 at the same time.

The clutch disks must be even.

10 steel lamella

4 – may not have any recesses.

11 lining disks

5, wear limit 2.65 mm

Inner clutch hub

6 – check the outer and inner teeth for wear.

Needle bearing

7 – check for wear.

Springs in the outer clutch hub

8

Springs dampen the drive train from the primary drive to the clutch. Check these springs in addition to performing the regular

wear tests. Try to turn the outer clutch hub when the engine is blocked – you should not feel any backlash.

NOTE: the outer clutch hub must have a supporting ring with a thickness of 1 mm - see Technical Information, Chapter 1.

Check the sides of the clutch pressure booster

9 for wear.

Loading...

Loading...