6-9

1

2

3

4

5

6

7

8

9

bk

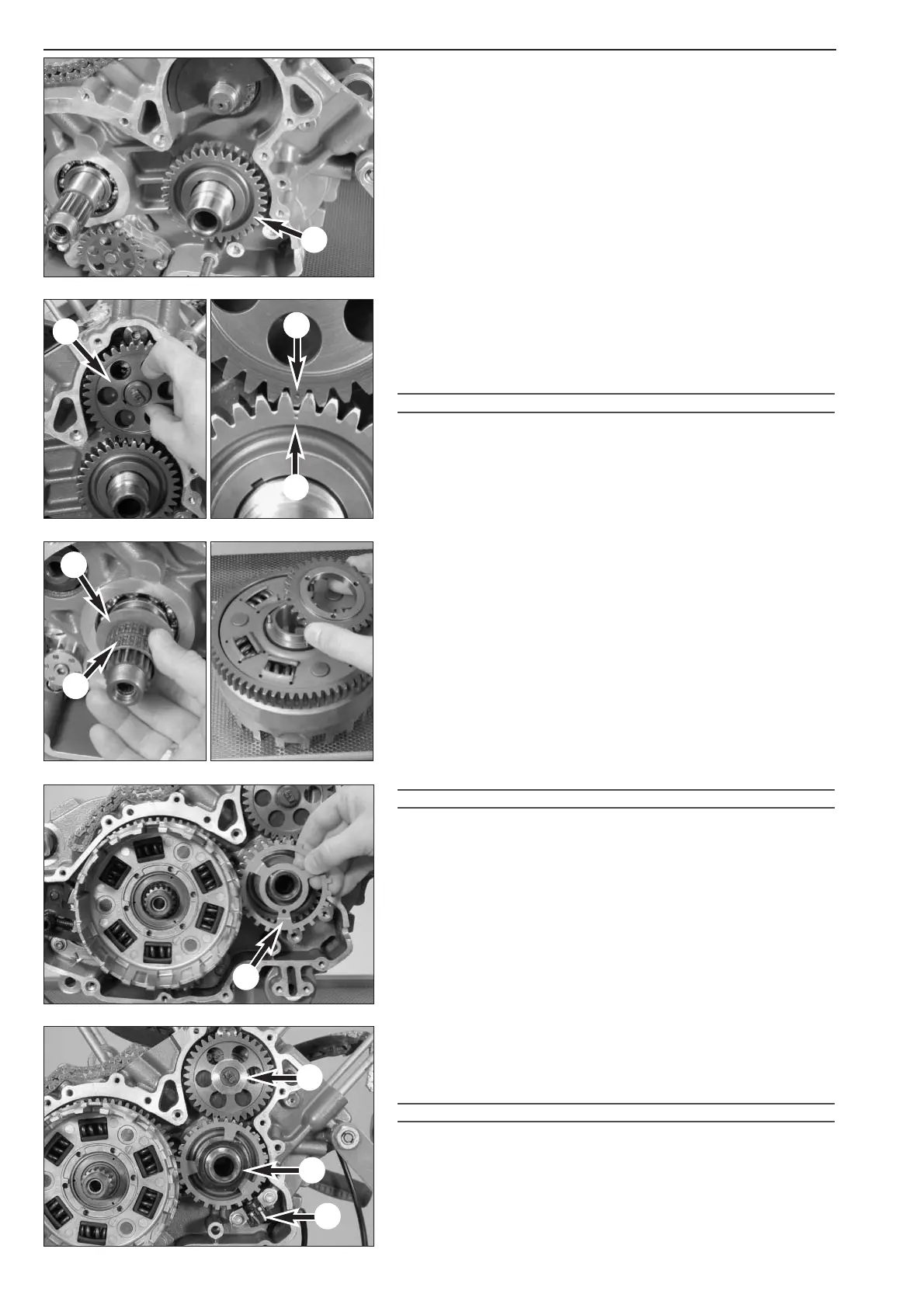

Primary pinion

– Mount the woodruff key for the primary pinion in the shaft groove (if

dismounted).

– Mount the primary pinion

1 with the longer collar towards the rear.

The bore for the pickup ring must face towards the outside.

– Mount the gear wheel of the balancer shaft

2 with the collar facing

the back (up to the 2004 model).

– From the 2005 model: slide on the preassembled spreader drive,

making sure the drive wheel and tensioning wheel do not fall apart;

pull out the pin.

!

CAUTION

!

T

URN THE BALANCER SHAFT UNTIL THE MARKS ON GEARS FOR THE CRANKSHAFT

3 AND BALANCER SHAFT 4 COINCIDE AS SHOWN IN THE ILLUSTRATION. MAKE

SURE THE TIMING CHAINS DO NOT GET CAUGHT

.

NOTE: when the marks coincide the first cylinder of the engine is in

the TDC position.

– Slide a 30.3 x 50 x 2 mm spacer washer

5 and a needle bearing 6

on the clutch shaft.

– Mount the gear for the oil pump drive on the back of the outer

clutch hub. The gear is secured by 3 needle rollers.

Outer clutch hub

– When slipping the outer clutch hub onto the shaft, leave enough

room for the pickup ring

7 which is held in place by a pin.

!

CAUTION

!

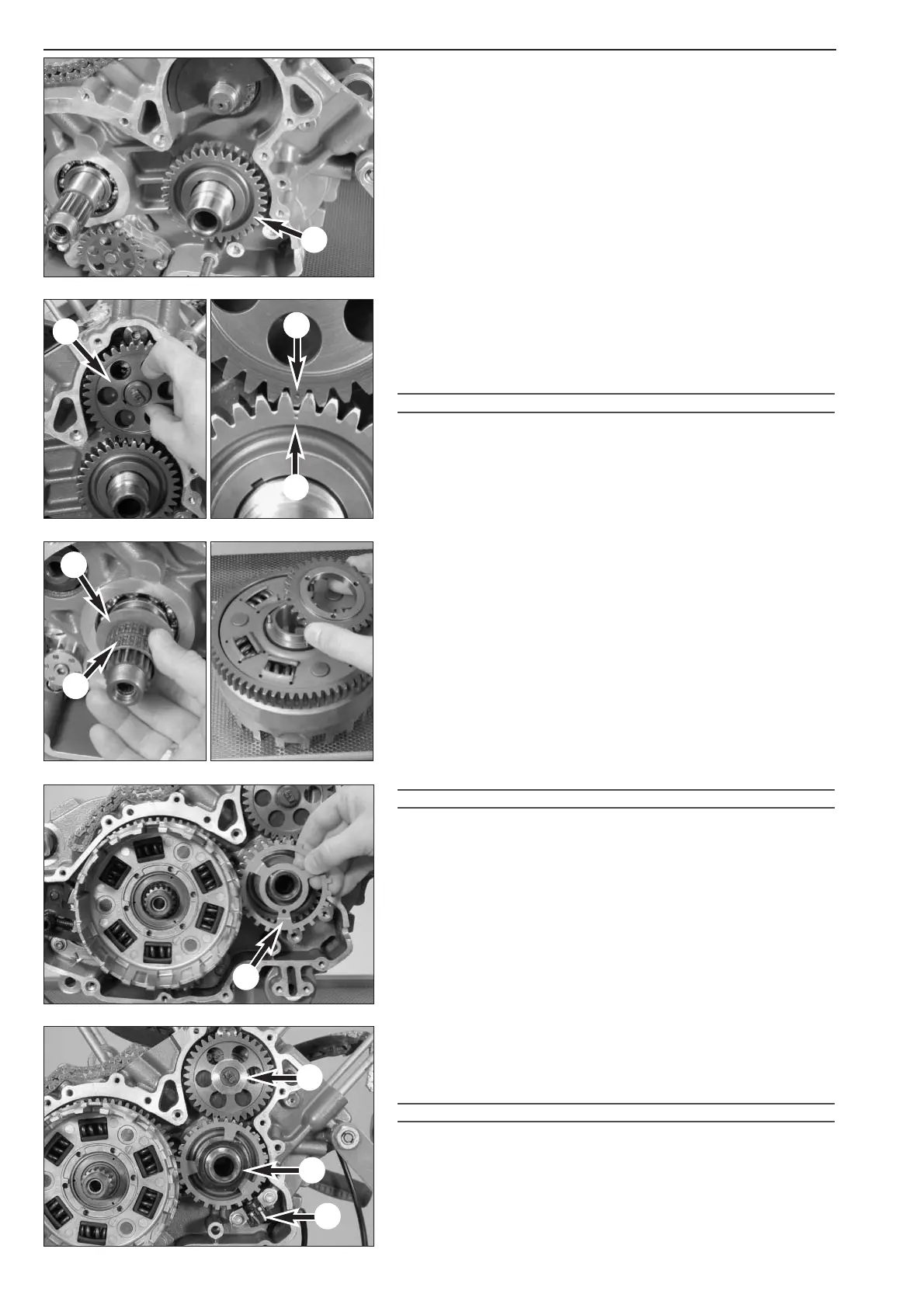

–

T

HE PIN ON THE PICKUP RING MUST ENGAGE IN THE HOLE OF THE PRIMARY PINION

.

–T

HE PICKUP RING IN

CARBURATOR AND INJECTION MODELS ARE

DIFFERENTIATED BY THE POSITION OF THE

"TOOTH GAP"; THEY CANNOT BE

INTERCHANGED

.

– After mounting the ring gear on the crankshaft, push the outer

clutch hub up to the stop, moving the oil pump wheel back and

forth to make the procedure easier.

– Mount a 33.2 x 46 x 2 disk and nut

8 (46 mm) on the primary

pinion (LH thread). Apply Loctite 243 to the nut and tighten to

130 Nm.

– Mount a 20.2 x 33 x 1.5 mm disk and nut

9 on the balancer shaft.

Apply Loctite 243 to the nut and tighten to 150 Nm (up to the

2004 model).

– Mount the washer 20.2x34x1 mm and the spring washer

30.5x46.5x0.6-1.5, apply Loctite 243 to the nut 9 (A/F 30 mm) on

the balancer shaft and mount, tighten the nut to 120 Nm (from the

2005 model).

!

CAUTION

!

T

HE GEAR WHEEL AND BALANCER SHAFT ARE PRESTRESSED STARTING WITH THE

2005 MODEL; THE NUT ON THE BALANCER SHAFT MAY ONLY BE TIGHTENED TO

120 NM OTHERWISE THE SPREADER DRIVE WILL BE DAMAGED.

– Screw on the pickup

bk. Apply Loctite 243 to the bolts (M6x16) and

tighten to 10 Nm. Press the cable duct into the recess in the case.

NOTE: the gap between the pickup and the pickup ring must be between

0.6 and 1.0 mm (950) or between 0.4 and 0.6 mm (990).

Loading...

Loading...