CHECKING

AND

CLEANING

DRAIN

1.

Inspect the drain on the

fi

lt

er

housing cover and

clean out any

dirt or debris.

2. Replace

any drain that is. crac.ked or shm•

vs

any

signs

of

hardening

or

detenoratJon.

3. Wipe any accumulation

of

oil or gas from the filter

housing

and

drain.

Valve/Tappet

Clearance

(Feeler

Gauge

Procedure)

To check and adjust

va

lve/tappet clearance, use the

following procedure.

•NOTE:

The seat, left-side and

right

-si

de

engine

covers, and gas

tank

must

be removed

for

this

pro-

cedure.

1.

Remove the timing inspection plug and spark

plug: then

remO\

~

e

the tappet . covers (for J??re

deta.iled infom1atton, see

SectJOn

3 - Serv1cmg

T

op

-Side Components).

2.

Rotate

th

e crankshaft to the TDC position on the

com

pr

ession stroke.

•NOTE:

At

this

point

,

the

rocker

arms

and adjuster

screws

must

not

have

pre

ssure

on

them.

2-6

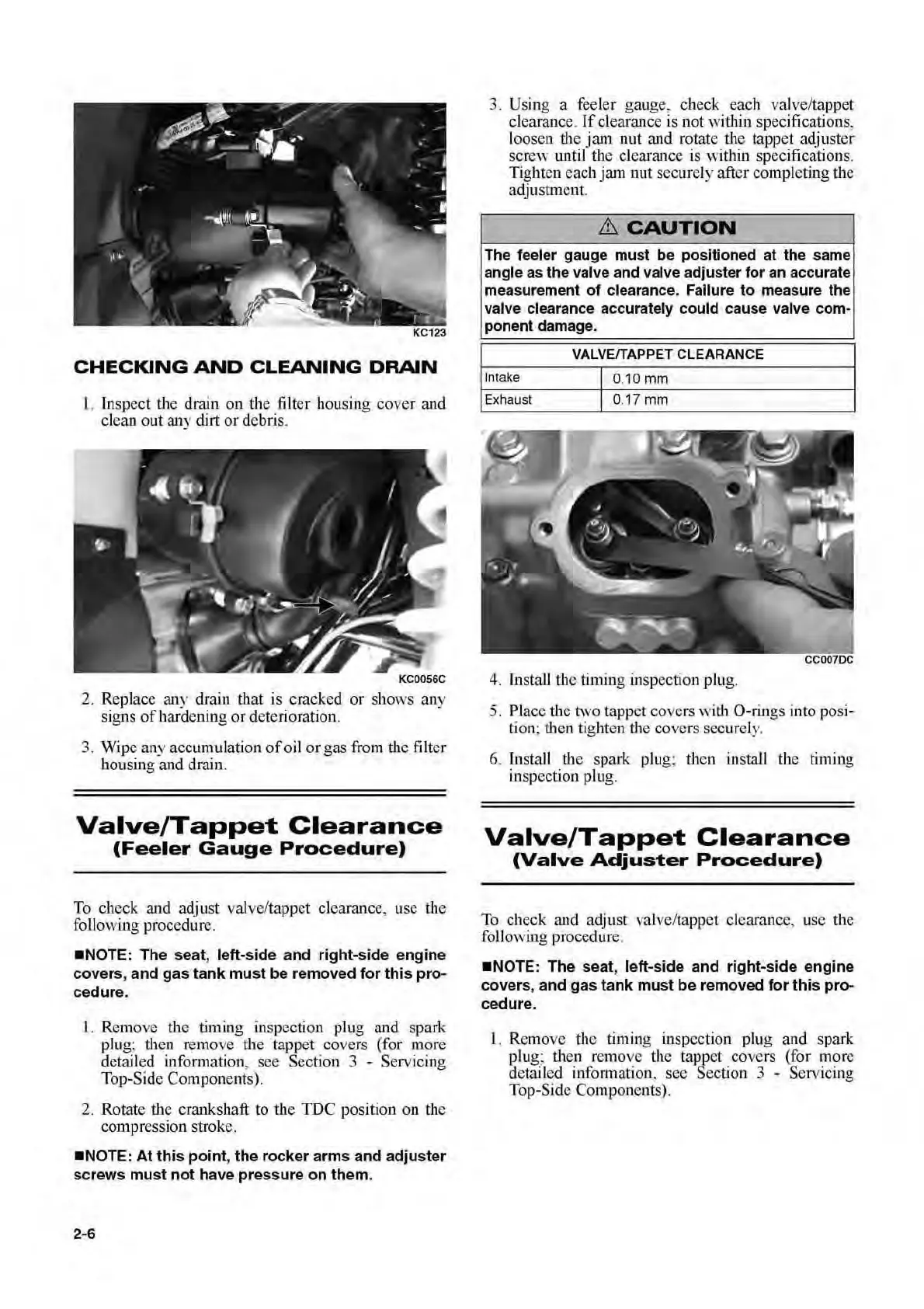

3. Using a feeler gauge, check.

e~c

h

v

a!

ve/

t~pp

et

cl

ea

rance.

If

clearance is not w

1thm

spec

rfi

ca~tons,

loosen the jam nut and

r

~tate

.t

h ~

tapp

e.t

adj~1ster

screw lmtil the cl

ea

rance IS w

1thm

spec

rfi

c~tJons.

Tighten each jam nut secur

ely

after completJng the

adjustment.

&

CAUTION

The feeler gauge must be positioned at the same

angle as the valve and valve adjuster for an accurate

measurement

of

clearance. Failure

to

measure the

valve clearance accurately could cause valve com-

ponent damage.

VALVE/TAPPET

CLEARANCE

Intake

J 0.10

mm

Exhaust

J 0.17

mm

4.

Install the tinting inspection plug.

5.

Place the two tappet covers with

0-rin

gs

into

po

si-

tion: then tighten the covers securely.

6. Install

th

e spark plug: then install the timing

in

spection plug.

Valve/Tappet

Clearance

(Valve

Adjuster

Procedure)

To check and adjust val

ve

/tapp

et

clearance, use the

foliO\\ri.ng

procedure.

•NOTE

: The seat, left-side and right-side engine

covers

, and gas

tank

must

be

removed

for

this

pro-

cedure.

l.

Remove the tim

in

g

in

spec

t.ion

plug and spark

plug: then remove the tappet. covers (for

~?re

detailed information. see S

ectiO

n 3 - Serv

1cm

g

Top-Side Components).

Loading...

Loading...