Drive

System

• NOTE:

Some

photographs

and

illustrations

used

in

this

section

are

used

for

clarity

purposes

only

and

are

not

designed

to

depict

actual

conditions.

• NOTE:

Critical

torque

specifications

are

located

in

Section

1.

• NOTE:

Specifications

regarding

the

gear

cases

(capacities,

ll.bricant

type,

etc.)

can

be

found

in

Section

1

of

this

manual.

Ring Gear Backlash 0.28-0.38 mm (0.011-0.015 in.)

Ring Gear End

Play 0.1-0.2

mm

(0.004-0.008 in.)

GENERAL

INFORMATION

All

gear

cases are tagged beneath a cover bolt. This tag

is marked with a production date code, sequence code,

and

a ratio code.

The

"1"

or "3.1" on the lower-right

comer

indicates a

3.1:1

gearsetratio

(11:34teeth).

The die-cast aluminum housings have been assembled

with thread-rolling screws (trilobular). When

assem-

bling with these screws, start the screws carefully into

the housing; then use the

following torque values.

New Reassembled

Size

Housing Housing

M6 (Torx

T-30

Recess) 8-9.5 fl-lb 6.5-9 fl-lb

M8 (Torx

T-40

Recess) 25-31 fl-lb 21-25 fl-lb

M1

0 (Torx

T-50

Recess) 37-45.5 fl-lb 31-38 fl-lb

6-2

SPECIAL

TOOLS

A number

of

special tools

must

be available to the

technician

when

performing service procedures in this

section.

Description p/n

CV Boot Clamp Tool

Internal

Hex Socket

Pinion Gear/Shaft

Removal

Tool

Slide Hammer Kit

Gear

Case Seal Installer

Tool

E014

• NOTE:

Special

tools

are available

from

the

KYMCO

Spare

Parts

Department.

Front

Drive

Actuator

• NOTE:

The

actuator

is

not

a

serviceable

compo-

nent.

If

it

is

defective,

it

must

be

replaced.

• NOTE: The

actuator

wi

II

operate

only

when

the

ignition

switch

is

in

the

ON

position.

The front drive actuator is located on the side

of

the

front drive input housing.

With

the engine stopped and

the ignition switch in the

ON

position, a momentary

"whirring" sound can be heard each time the front

drive selector switch is shifted.

If

no sound is heard,

see Section 5.

Ifthe

actuator runs constantly or makes

squealing

or

grinding sounds, the actuator

must

be

replaced.

REMOVING

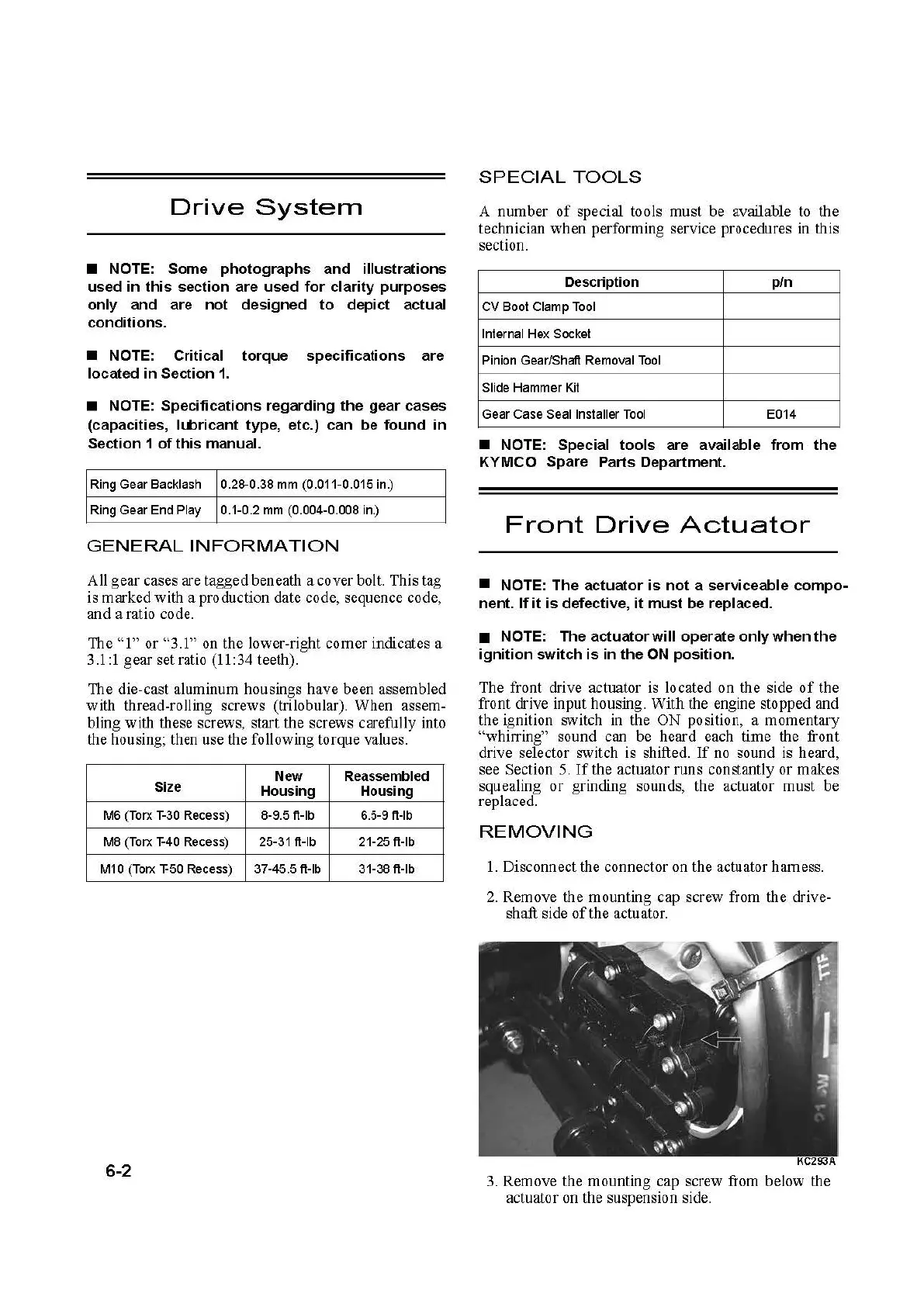

1. Disconnect the connec

tor

on the actuator harness.

2. Remove the mounting cap screw from the

drive-

shaft side

of

the actuator.

3. Remove the mounting cap screw from below the

actuator on the suspension side.

Loading...

Loading...