Diagnostic information 2-3

5025-2xx, 4xx

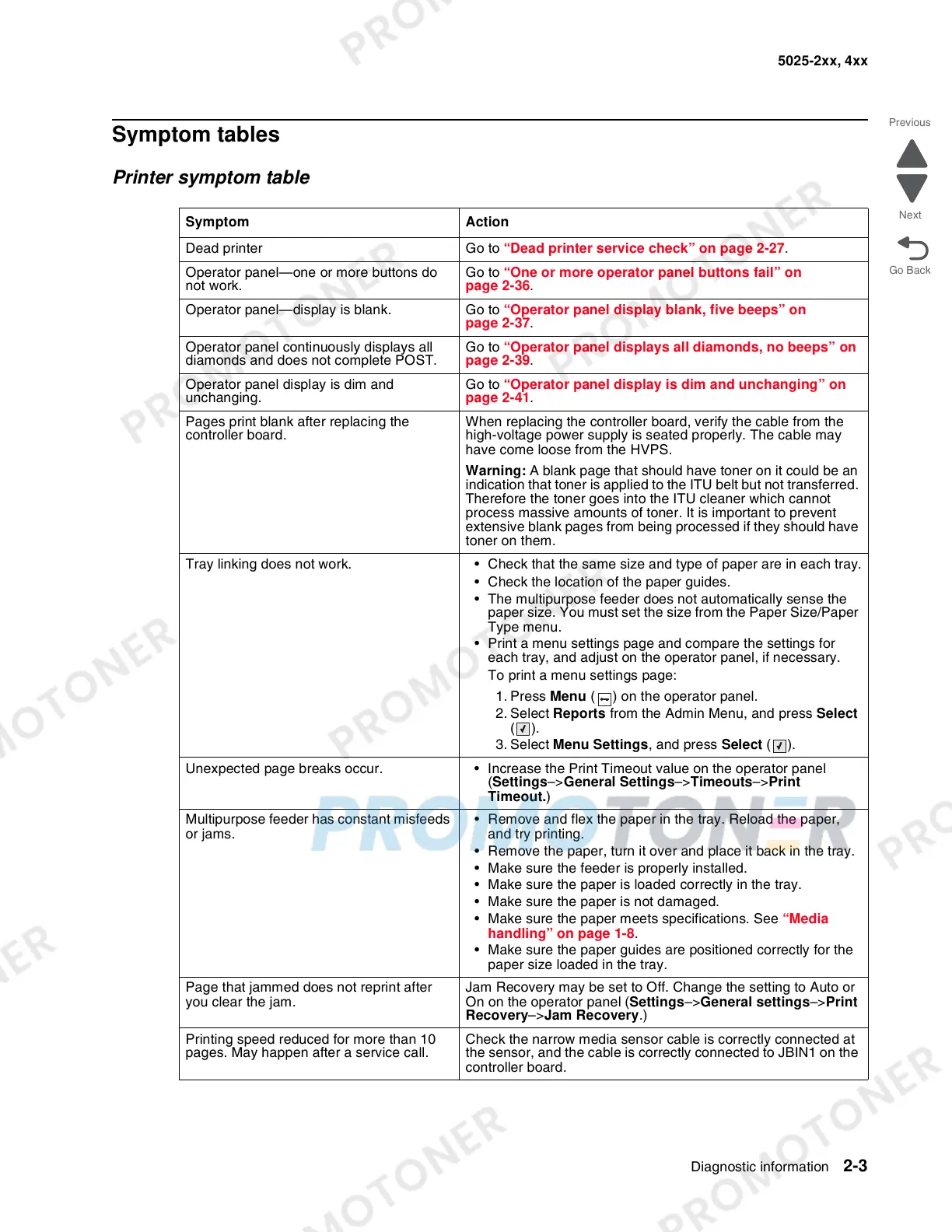

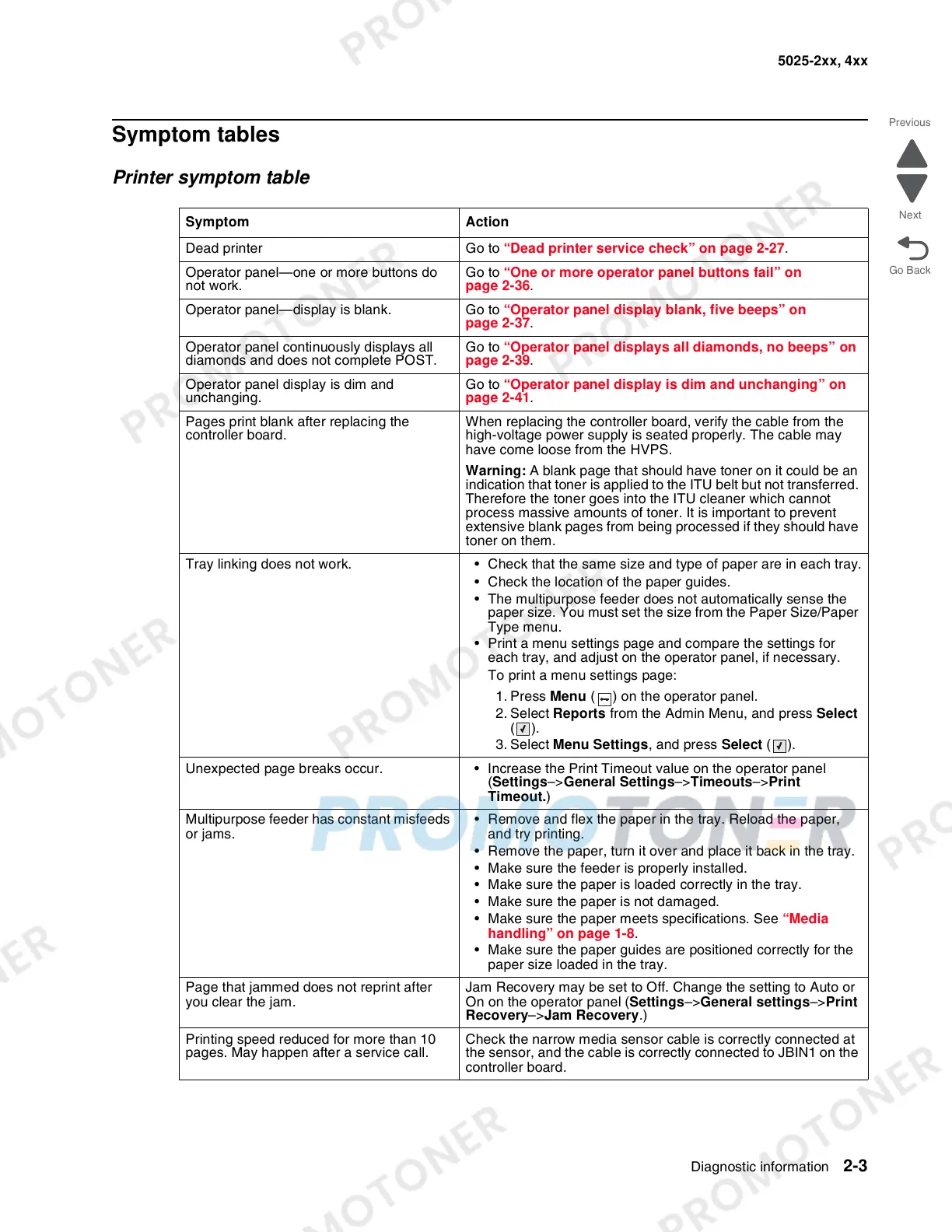

Symptom tables

Printer symptom table

Symptom Action

Dead printer Go to “Dead printer service check” on page 2-27.

Operator panel—one or more buttons do

not work.

Go to “One or more operator panel buttons fail” on

page 2-36.

Operator panel—display is blank. Go to “Operator panel display blank, five beeps” on

page 2-37.

Operator panel continuously displays all

diamonds and does not complete POST.

Go to “Operator panel displays all diamonds, no beeps” on

page 2-39.

Operator panel display is dim and

unchanging.

Go to “Operator panel display is dim and unchanging” on

page 2-41.

Pages print blank after replacing the

controller board.

When replacing the controller board, verify the cable from the

high-voltage power supply is seated properly. The cable may

have come loose from the HVPS.

Warning: A blank page that should have toner on it could be an

indication that toner is applied to the ITU belt but not transferred.

Therefore the toner goes into the ITU cleaner which cannot

process massive amounts of toner. It is important to prevent

extensive blank pages from being processed if they should have

toner on them.

Tray linking does not work. • Check that the same size and type of paper are in each tray.

• Check the location of the paper guides.

• The multipurpose feeder does not automatically sense the

paper size. You must set the size from the Paper Size/Paper

Type menu.

• Print a menu settings page and compare the settings for

each tray, and adjust on the operator panel, if necessary.

To print a menu settings page:

1. Press Menu ( ) on the operator panel.

2. Select Reports from the Admin Menu, and press Select

().

3. Select Menu Settings, and press Select ().

Unexpected page breaks occur. • Increase the Print Timeout value on the operator panel

(Settings–>General Settings–>Timeouts–>Print

Timeout.)

Multipurpose feeder has constant misfeeds

or jams.

• Remove and flex the paper in the tray. Reload the paper,

and try printing.

• Remove the paper, turn it over and place it back in the tray.

• Make sure the feeder is properly installed.

• Make sure the paper is loaded correctly in the tray.

• Make sure the paper is not damaged.

• Make sure the paper meets specifications. See “Media

handling” on page 1-8.

• Make sure the paper guides are positioned correctly for the

paper size loaded in the tray.

Page that jammed does not reprint after

you clear the jam.

Jam Recovery may be set to Off. Change the setting to Auto or

On on the operator panel (Settings–>General settings–>Print

Recovery–>Jam Recovery.)

Printing speed reduced for more than 10

pages. May happen after a service call.

Check the narrow media sensor cable is correctly connected at

the sensor, and the cable is correctly connected to JBIN1 on the

controller board.

Loading...

Loading...