DO NOT FORCE THE PROPELLER INTO PLACE.

Step 7

Install the propeller nut and torque to 50-ft-lbs.

Step 8

Install a new cotter pin and bend the ends around the shaft to lock

the propeller on the shaft.

Step 3

Rotate the propeller slowly. There should be no more than 3/32-

inch variance between the blades. If the propeller is damaged, see

an authorized MasterCraft dealer.

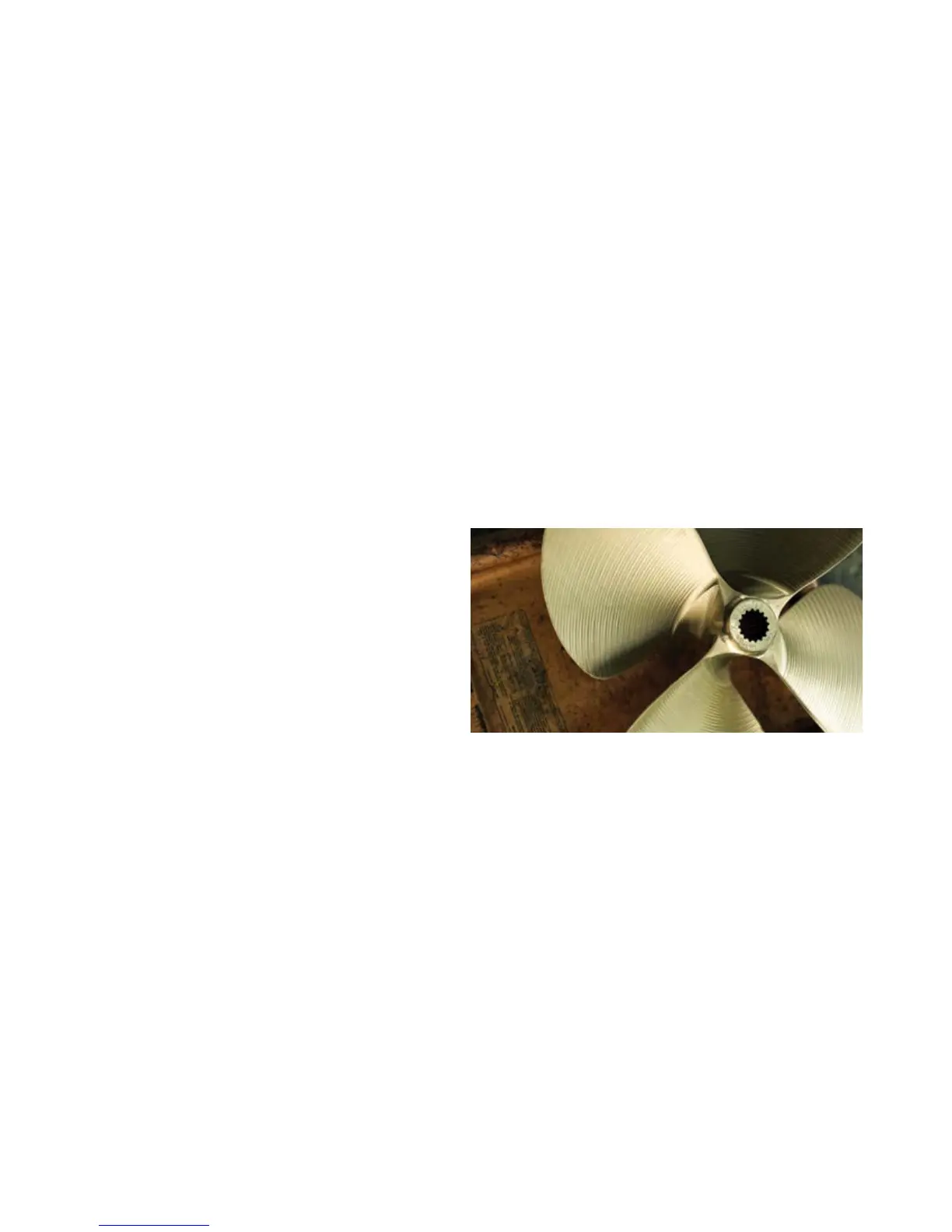

CHANGING PROPELLERS

Step 1

Ensure the engine is OFF and the engine safety starting switch is

disconnected.

Step 2

Remove and discard the cotter pin.

Step 3

Remove the propeller nut.

Step 4

Tap the center hub of the propeller with a rubber mallet to release

the propeller. Inspect the shaft and propeller splines for damage.

Step 5

Thoroughly clean and apply a light coat of waterproof marine multi-

purpose grease to the splined area of the shaft and propeller.

Step 6

Align the splines and carefully install the propeller onto the shaft.

Loading...

Loading...