Powerhead

90-8M0065421 NOVEMBER 2012 Page 4A-25

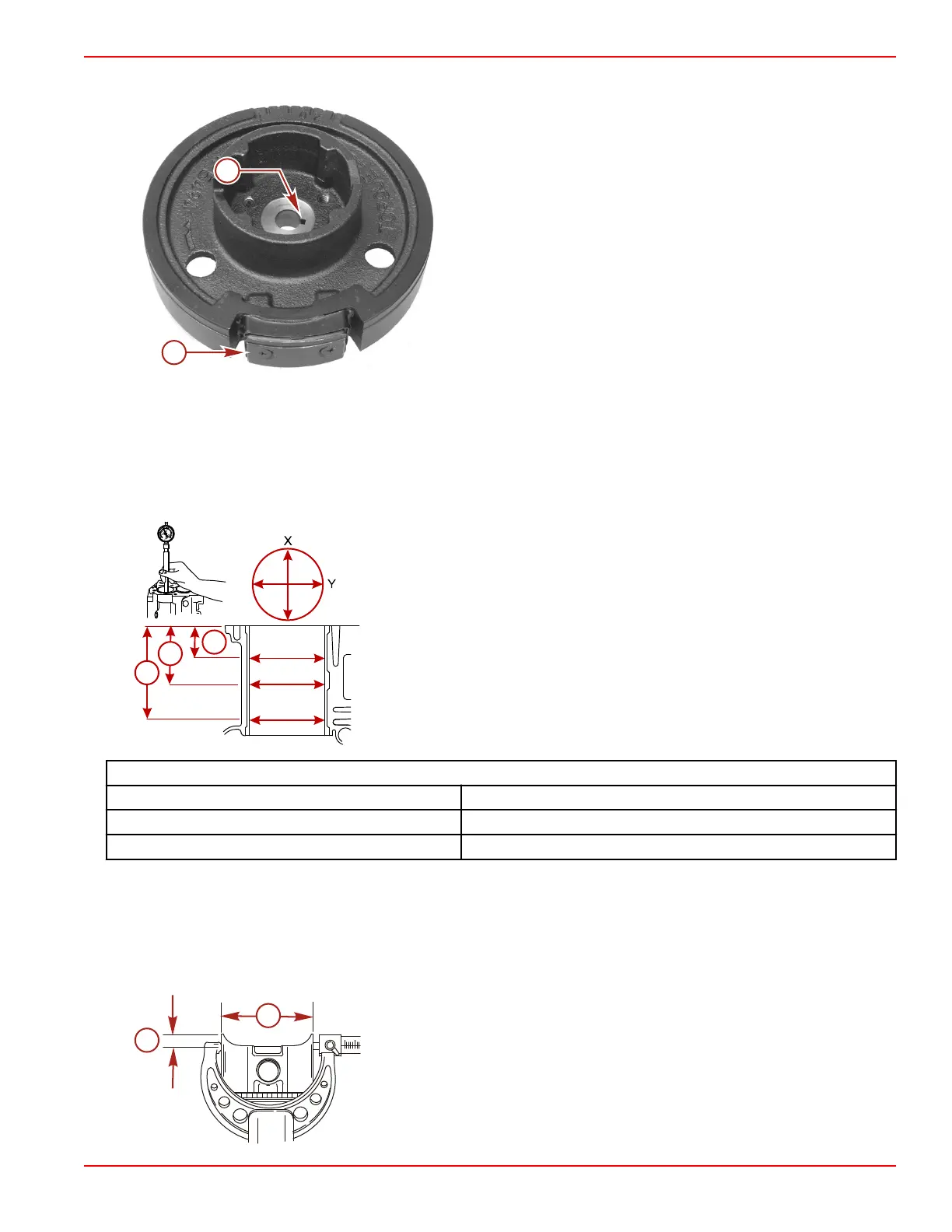

2. Ensure the flywheel magnet is secured to the flywheel.

a - Keyway

b - Magnet

Cylinder Bore Measurement

1. Inspect the water jacket areas for mineral deposit and blockage. Clean the water jacket area as needed.

2. Inspect the surface of the cylinder bores. Deep scoring will require the cylinder block to be bored oversize and finished

honed.

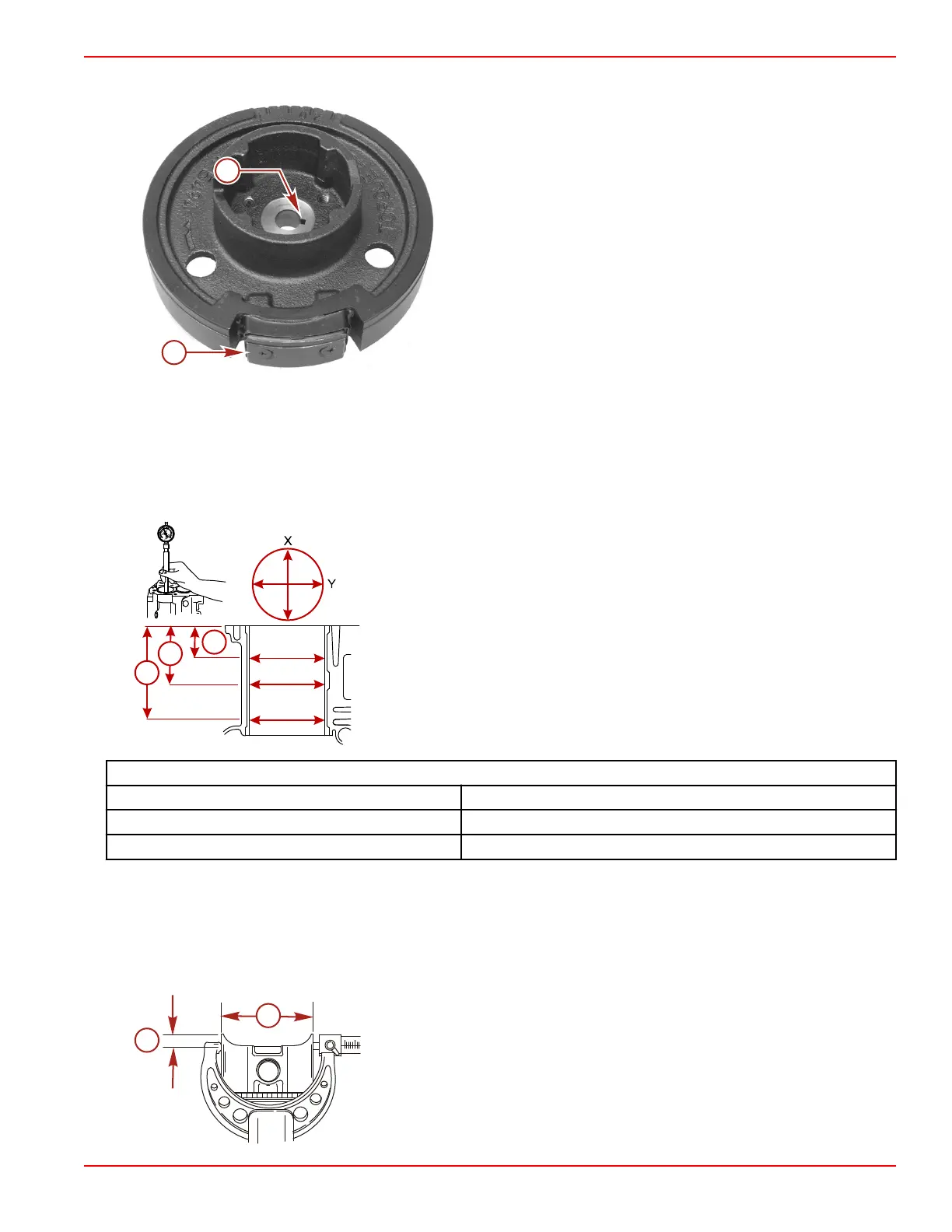

3. Measure the cylinder bore in six places with a cylinder bore gauge. Determine the maximum taper/out of round of the

cylinder bore.

a - 60 mm (2.36 in.)

b - 40 mm (1.575 in.)

c - 20 mm (0.787 in.)

Cylinder Bore

Maximum taper/out of round 0.06 mm (0.00236 in.)

Standard bore finish hone 55 ± 0.01 mm (2.165 ± 0.00039 in.)

Oversize bore finish hone 55.5 ± 0.01 mm (2.185 ± 0.00039 in.)

Piston

Diameter

1. Inspect the piston. Replace if damaged or worn.

2. Measure the piston at a point 7.0 mm (0.276 in.) from the bottom of the piston skirt and 90° from the wrist pin. Replace the

piston if out of specification.

a -

Piston diameter

b - 7.0 mm (0.276 in.) from bottom of piston skirt

3129

b

c

a

Loading...

Loading...