Maintenance

Page 1B-8 90-8M0065421 NOVEMBER 2012

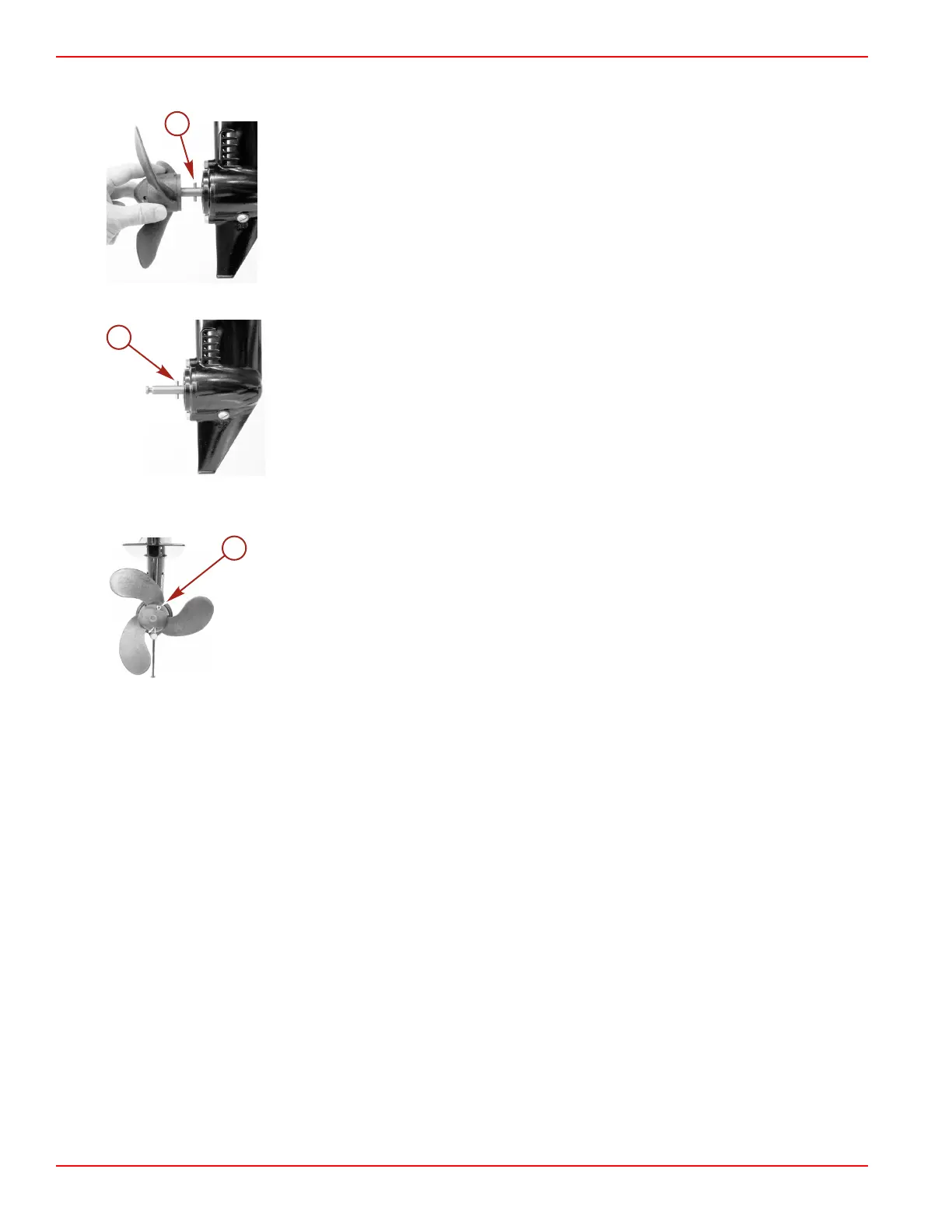

4. Pull the propeller straight off the shaft. Retain the drive pin. If the propeller is seized to the shaft and cannot be removed,

have the propeller removed by an authorized dealer.

a - Drive pin

5. Insert the drive pin into the propeller shaft.

a - Drive pin

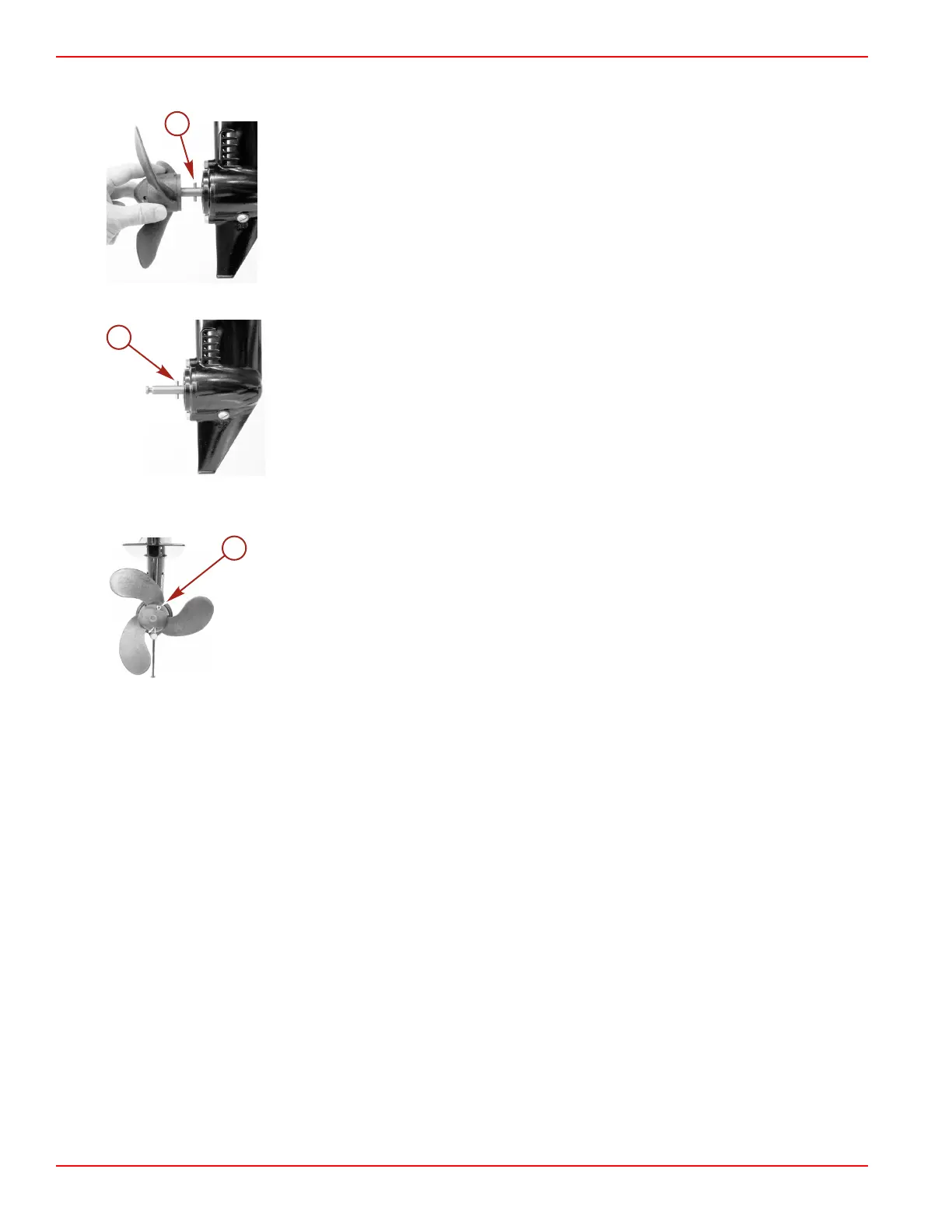

6. Slide the propeller onto the shaft, making sure the slot in the propeller engages with the drive pin.

7. Install the cotter pin through the hole in the propeller and bend the cotter pin ends.

a - Cotter pin

Gearcase Lubrication

When adding or changing gearcase lubricant, visually check for the presence of water in the lubricant. If water is present, it may

have settled to the bottom and will drain out prior to the lubricant, or it may be mixed with the lubricant, giving it a milky colored

appearance. If water is noticed, have the gearcase checked by your dealer. Water in the lubricant may result in premature

bearing failure or, in freezing temperatures, will turn to ice and damage the gearcase.

Examine the drained gearcase lubricant for metal particles. A small amount of metal particles indicates normal gear wear. An

excessive amount of metal filings or larger particles (chips) may indicate abnormal gear wear and should be checked by an

authorized dealer.

Draining Gearcase

1. Place the outboard in a vertical operating position.

2. Place drain pan below outboard.

3. Remove vent plug and fill/drain plug and drain lubricant.

Loading...

Loading...