Powerhead

Page 4A-32 90-8M0065421 NOVEMBER 2012

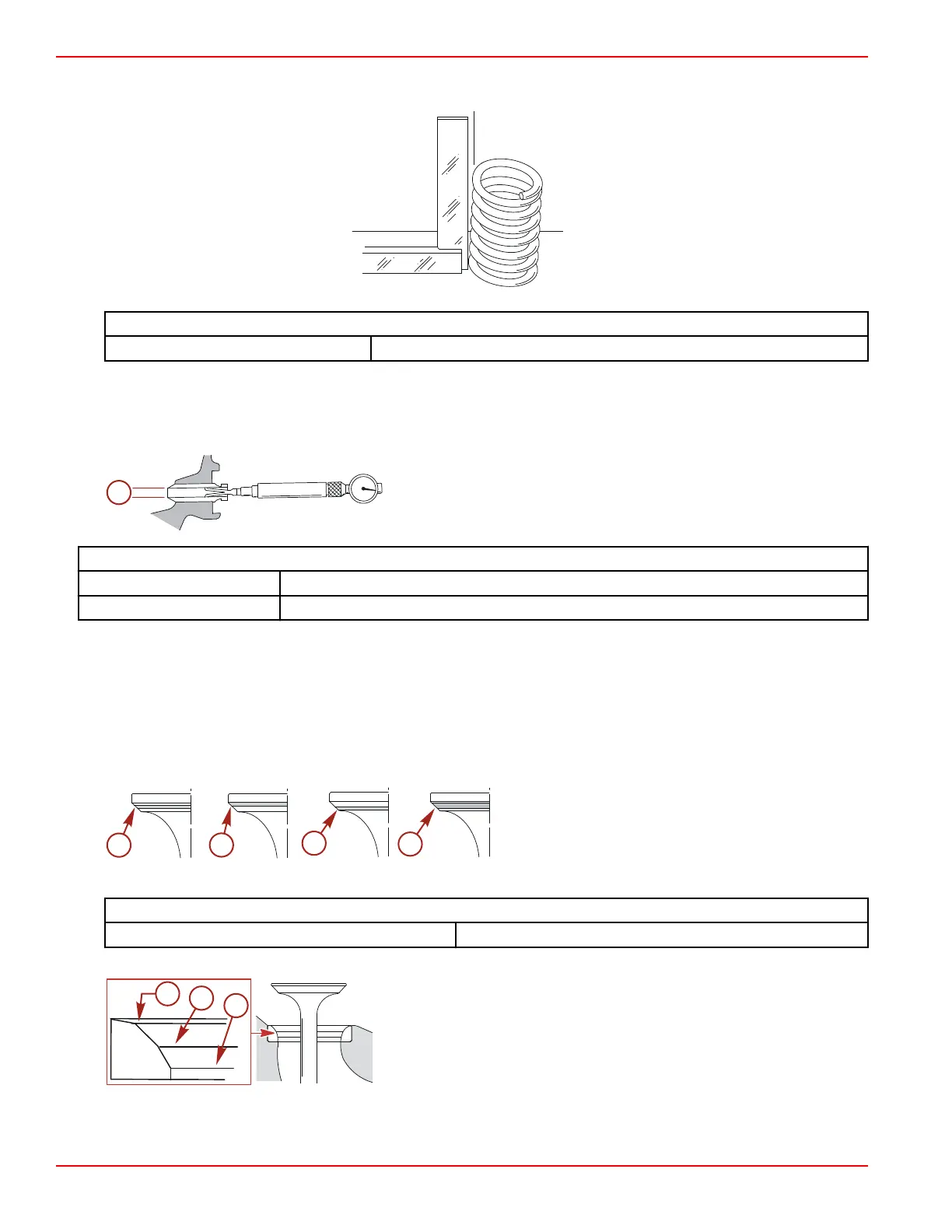

NOTE: Check each spring on a flat surface using a square. Rotate spring and check space between the top coil and

square.

Valve Spring

Tilt limit 2.0 mm (0.0787 in.)

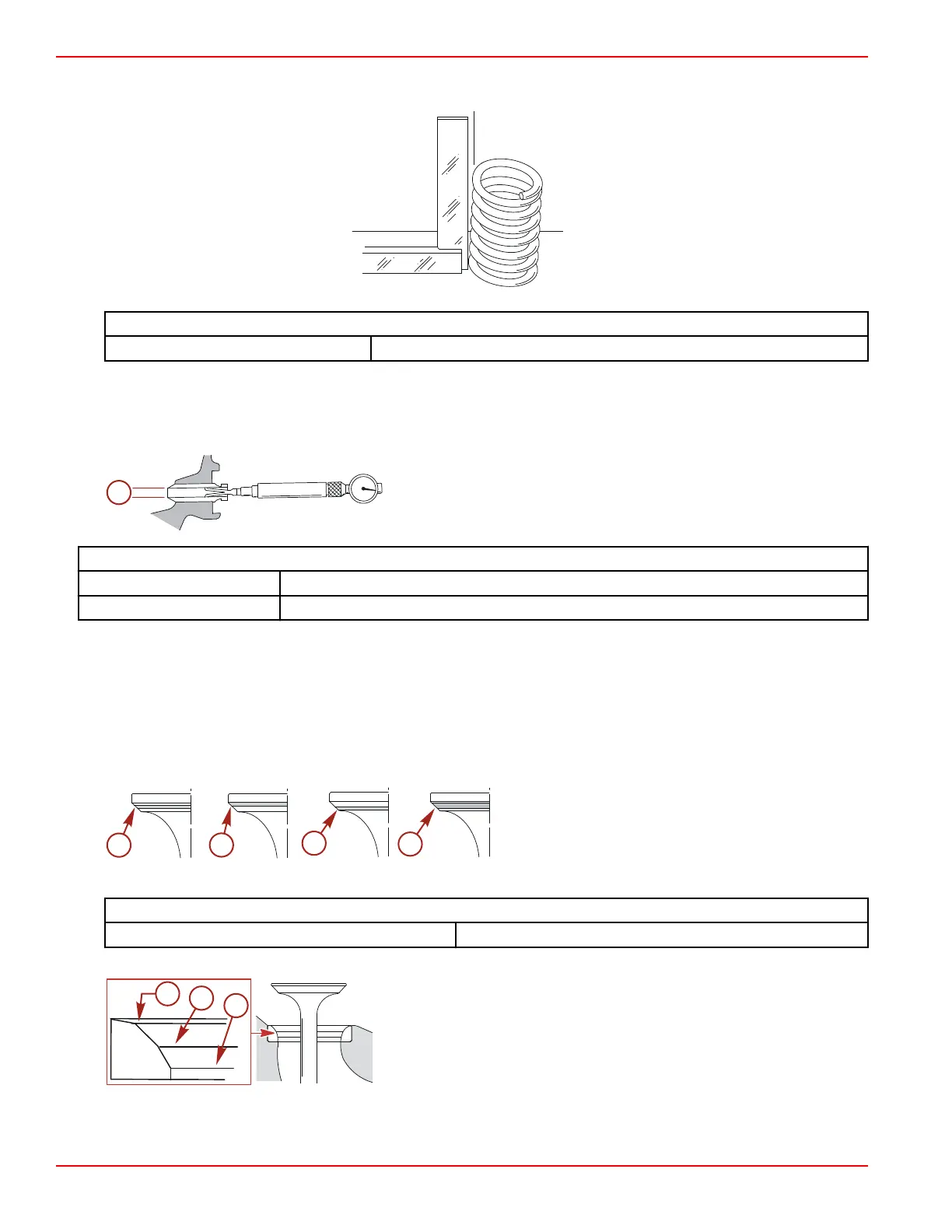

Valve Guides

Measure the valve guide inner diameter. If valve guide wear is out of specification, replace the cylinder head.

a - Valve guide I.D.

Valve Guide I.D.

Intake 5.51–5.55 mm (0.217–0.2185 in.)

Exhaust 5.51–5.57 mm (0.217–0.2193 in.)

Valve Seat Reconditioning

1. Clean the carbon deposits from the combustion chambers and valve seats. Check the valve seats for pitting.

2. Several different types of equipment are available for reseating valve seats. Follow the equipment manufacturers

instructions.

3. Apply a thin, even layer of mechanic's bluing dye (Dykem) onto the valve seat.

4. Insert the valve into the valve guide and lap the valve slowly on the valve seat.

5. Remove the valve and measure the valve seat contact pattern width. Resurface the valve seat if not in specification.

a - Correct valve seat contact width

b - Valve seat too high

c - Valve seat too low

d - Valve seat too wide

Valve Seat Contact Width

Intake and exhaust valve 1.0–2.0 mm (0.0393–0.0787 in.)

6. To reface a valve seat, use a 30°, 45°, and 60° valve seat cutting tool.

a -

30° angle

b - 45° angle

c - 60° angle

NOTE: When twisting the cutter, keep an even downward pressure to prevent chatter marks.

NOTE: After refacing the valve seat or replacing the valve and valve guide, the valve seat and valve face should be

lapped.

Loading...

Loading...