When the engine first starts, if there is a failure with the O2 sensor, or if for some reason, such as a failed fuel injector or spark

plug, the information reported by the sensor would require the PCM to add or subtract an excessive amount of fuel, the PCM

may revert to a default fuel table. It is then considered in open‑loop operation and will continue to use the last known good

values.

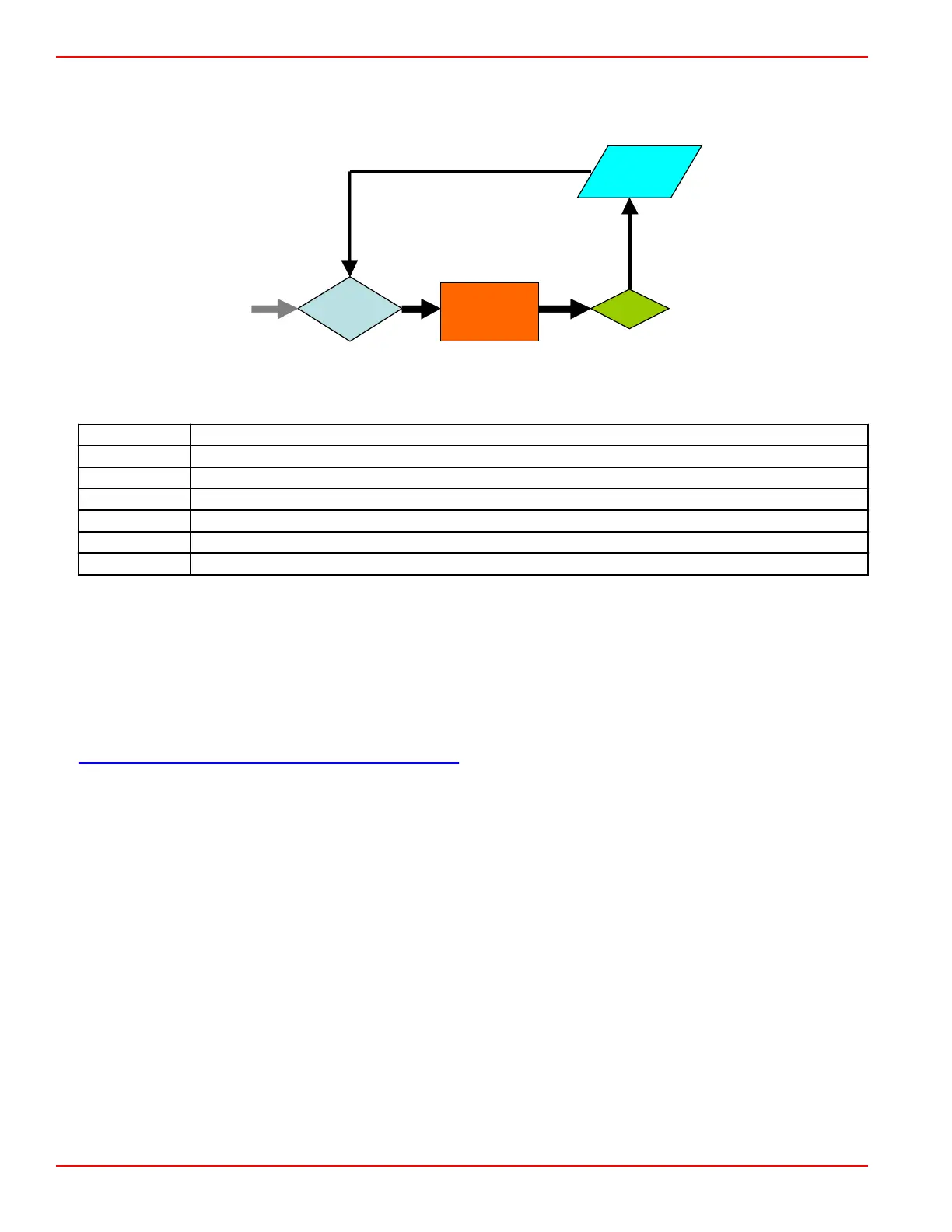

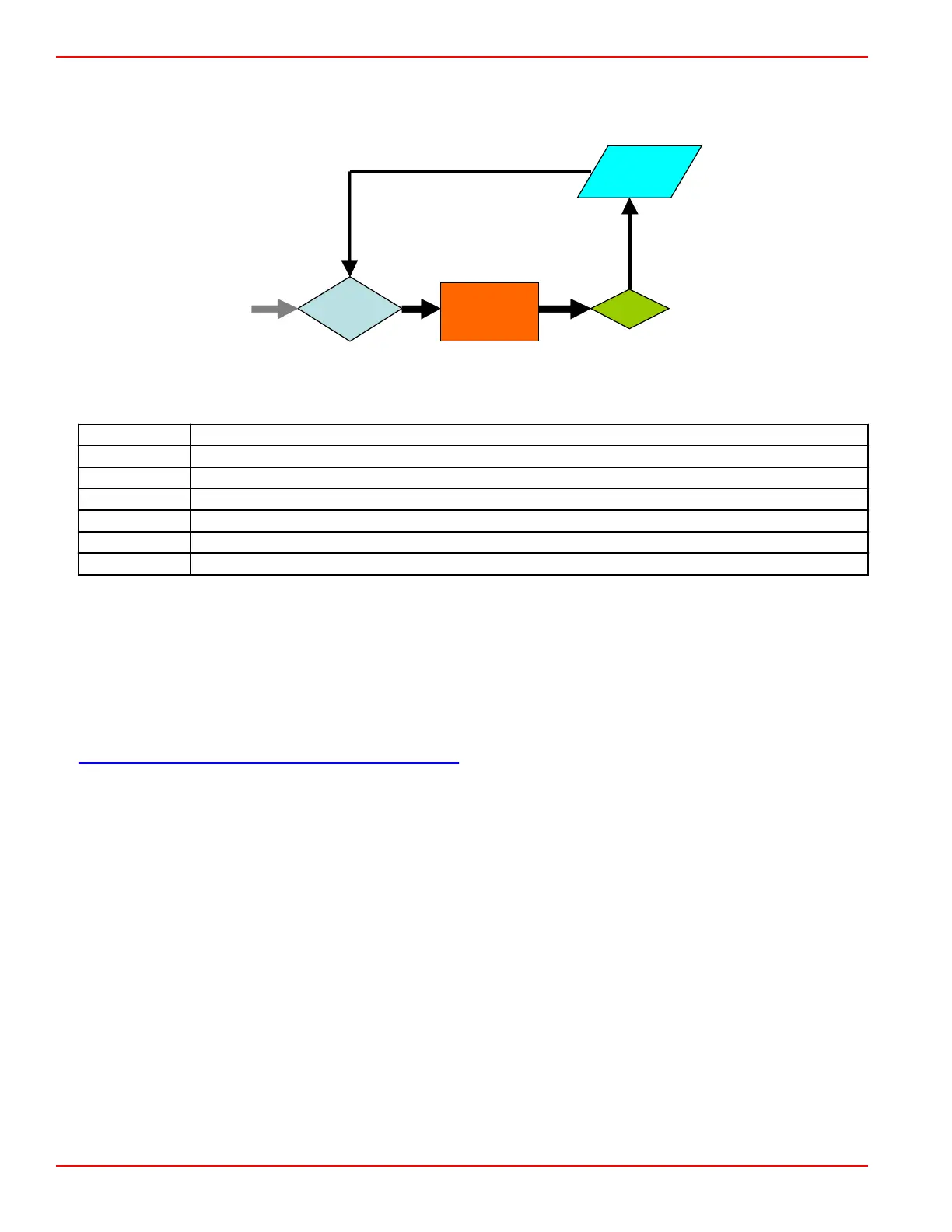

PCM

Fuel System

O2 Sensor

Combustion

67455

Closed-loop operation

Closed‑Loop Control Summary

Step

Action

1 PCM calculates air/fuel ratio.

2 Fuel system delivers the required air/fuel ratio to the combustion chamber.

3 Combustion occurs (power stroke).

4 Exhaust gases enter the exhaust manifold (exhaust stroke).

5 The oxygen sensor sends a signal to the PCM, delivering oxygen information.

The cycle returns to step 1.

The speed/density system depends on the engine being unmodified from its original production state. If the engine is modified

and its volumetric efficiency changes, the amount of air flow for a given RPM and air density will change, causing the fuel

injector operation calculated by the PCM to be incorrect.

Advanced Range Optimization

Advanced range optimization (ARO) is a software based feature which actively increases fuel economy under specific

operating conditions. It becomes active when the engine is set within a defined RPM range, and certain load conditions are

met. The status of ARO can only be monitored using CDS G3. In CDS G3, ARO is called Lean Burn. The main data point in

CDS G3 is LeanBurnCtrlState. To learn more about ARO, and lean burn control states, an informative video can be found at:

https://p.widencdn.net/dxaed0/Advanced‑Range‑Optimization.

Propulsion Control Module (PCM)

The propulsion control module (PCM) system monitors sensor inputs and controls fuel delivery and spark timing. Its

components are:

• PCM 112 assembly

• Wiring harness

• Input devices (sensors)

• Output devices (fuel injectors, ignition coils, etc.)

Description

The PCM 112 is a 112‑pin propulsion control module that manages engine conditions and closed‑loop engine operation based

on oxygen sensor feedback. The PCM 112 requires the use of a separate PCM power harness.

The PCM monitors the following engine sensor feedback to control fuel injector timing, pulse width, and ignition spark timing:

• Block water pressure sensor

• Camshaft position sensor

• Crankshaft position sensor

• Engine coolant temperature (ECT) sensor

• ESTOP or lanyard switch position

• Exhaust gas temperature (EGT) sensor

System Theory

Page 1B-4 © 2018 Mercury Marine 90-8M0146617 eng JULY 2018

Loading...

Loading...