If the motor will not run in the up direction, it may be either the up relay is not making contact to 12 volts or the down relay is not

making contact to ground. The opposite is true if the system will not run down. When the system is not energized, both relays

should connect the heavy trim motor leads to ground.

To test which relay is faulty if the trim system does not operate in one direction:

1. Remove the starboard intake plenum. Refer to the appropriate service manual for instructions.

2. Remove the relay from the bracket.

3. Partially remove the relay from the connector just far enough to reach the electrical contacts with the voltmeter lead.

4. Check for continuity between the heavy leads from the trim relays to ground.

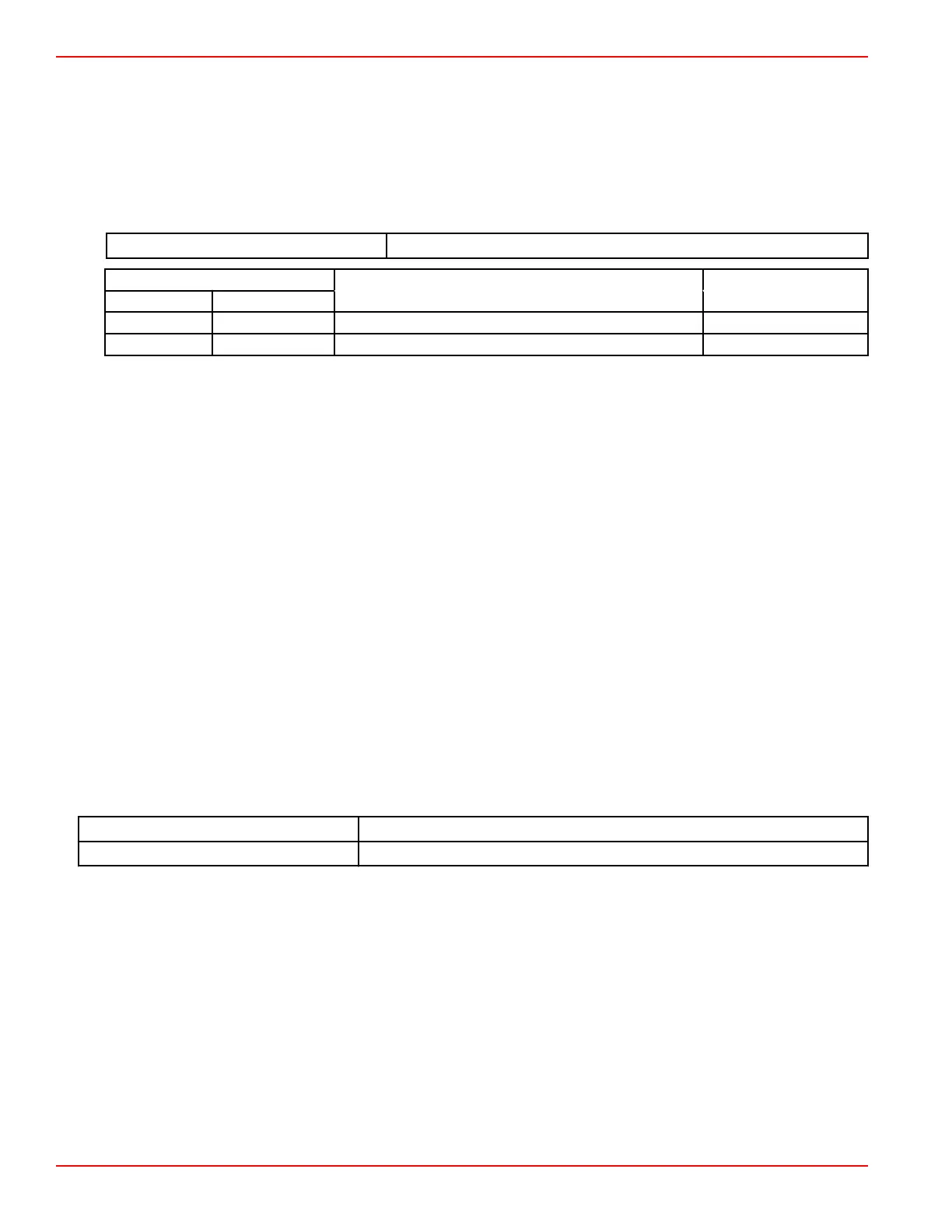

DMT 2004 Digital Multimeter 91‑892647A01

Meter Test Leads Meter Scale Reading (Ω)

Red Black

Green Ground Full continuity (R x 1) or Auto < 0.5 Ω

Blue Ground Full continuity (R x 1) or Auto < 0.5 Ω

5. Replace the relay that does not have continuity.

6. Connect a voltmeter to the heavy blue lead and to ground. There should be 12 volts on the blue lead when the up switch is

pushed and 12 volts on the green lead when the down switch is pushed. Replace the relay that does not switch the lead to

positive.

7. Install the starboard intake plenum. Refer to the appropriate service manual for instructions.

Trim Position Sensor Troubleshooting

Trim Position Sensor

The trim position sensor (TPS) is located on the port side of the outboard. It supplies the propulsion control module (PCM) with

trim position information. The PCM will generate and store a failure code when the TPS fails, and the alarm horn will sound.

The trim position sensor affects trim functions controlled by the helm trim switch and the cowl tilt switch.

With the engine running below 2000 RPM, the outboard can be tilted to any position in the trim range or the trailer range. If

above 2000 RPM, the trim range will be limited to prevent the outboard from reaching the trailer range. However, if you are

loading the boat onto the trailer for example, and tilt the outboard up into the trailer range while below 2000 RPM, the throttle

can be advanced to a maximum of 4400 RPM.

The following are some of the problems encountered with a faulty trim position sensor:

• Engine will trim higher than the set trim limit at speeds above 2000 RPM

• Engine trims past the maximum trailer limits

• Engine trims normally, but there are no trailer limits

Troubleshooting the Trim Position Circuit

Monitor the trim position sensor analog‑to‑digital counts (ADC) with CDS G3. Verify wiring harness integrity with a DMT 2004

digital multimeter or equivalent.

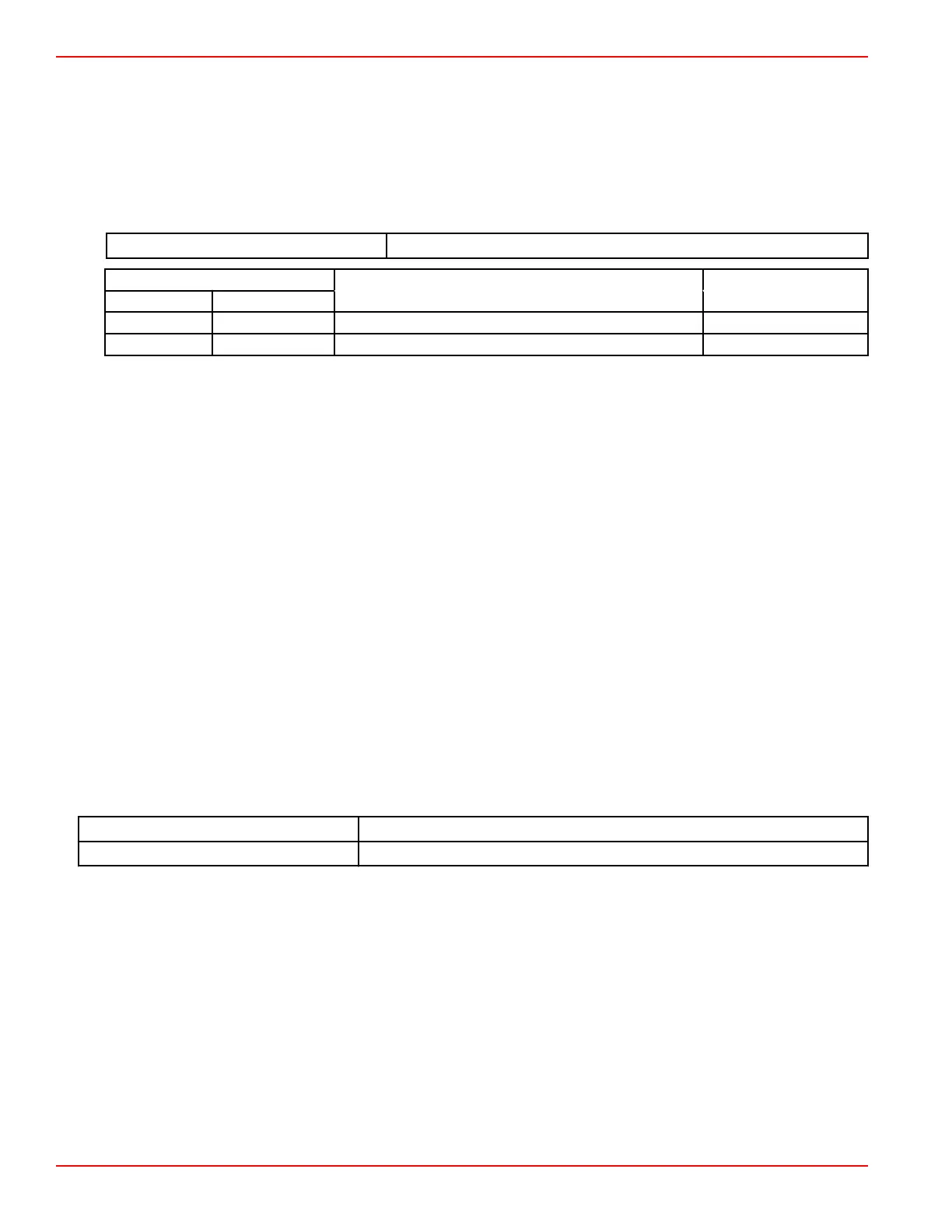

CDS G3 Interface Kit

8M0138392

DMT 2004 Digital Multimeter 91‑892647A01

Conventional Midsection (CMS) Power Trim

Page 6C-12 © 2018 Mercury Marine 90-8M0146617 eng JULY 2018

Loading...

Loading...