FX Series Programmable Controlers Applied Instructions 5

5-126

5.9.8 PID (FNC 88)

Operation:

This instruction takes a current value (S

2) and

compares it to a predefined set value (S

1). The

difference or error between the two values is then

processed through a PID loop to produce a

correction factor which also takes into account previous iterations and trends of the calculated

error. The PID process calculates a correction factor which is applied to the current output

value and stored as a corrected output value in destination device (D). The setup parameters

for the PID control loop are stored in 25 consecutive data registers S

3+0 through S3+24.

Points to note:

a) Every PID application is different. There will be a certain amount of “trial and error”

necessary to set the variables at optimal levels.

b) On FX

2N, FX2NC &FX1N MPUs a Pre-tuning feature is available that can quickly provide

initial values for the PID process. Refer to page 10-28 for more details.

c) The FX

1S does not have analog capabilities, it is therefore necessary to use RS232

communications to achieve basic PID operation.

d) As 25 data register are required for the setup parameters for the PID loop, the head address

of this data stack cannot be greater than D975. The contents of this data stack are

explained later in this section. Multiple PID instructions can be programmed, however each

PID loop must not have conflicting data registers.

e) There are control limits in the PLC intended to help the PID controlled machines operate in

a safe manner. If it becomes necessary to reset the Set Point Value (S

1

) during operation, it

is recommended to turn the PID command Off and restore the command after entering the

new Set Point Value. This will prevent the safety control limits from stopping the operation of

the PID instruction prematurely.

f) The PID instruction has a special set of error codes associated with it. Errors are identified in

the normal manner. The error codes associated with the PID loop will be flagged by M8067

with the appropriate error code being stored in D8067. These error devices are not

exclusive to the PID instruction so care should be taken to investigate errors properly.

Please see chapter 6, ‘Diagnostic Devices’ for more information.

g) A full PID iteration does not have to be performed. By manipulation of the setup parameters

P (proportional), I (Integral) or D (derivative) loops may be accessed individually or in a user

defined/selected group. This is detailed later in this section.

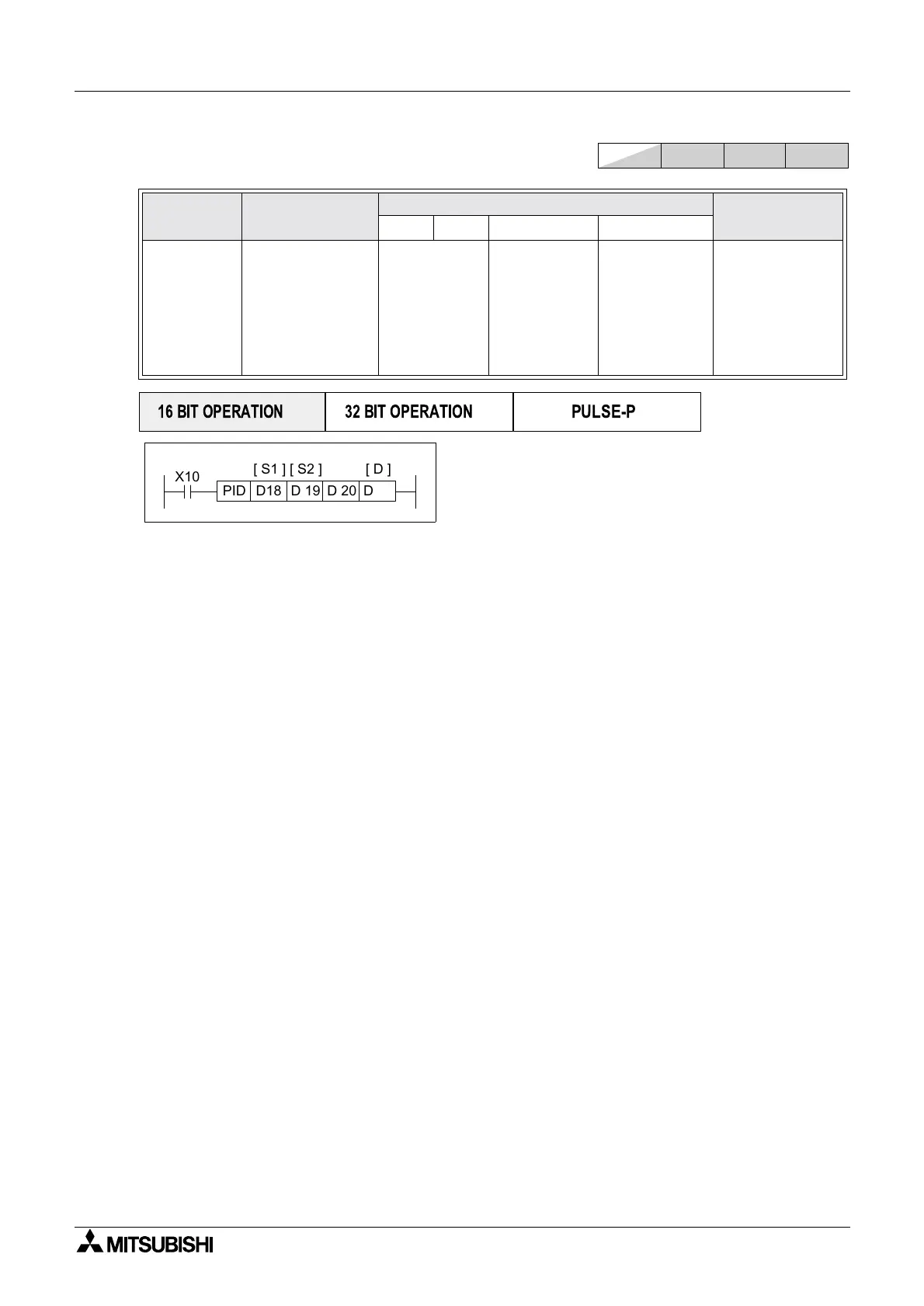

Mnemonic Function

Operands

Program steps

S

1 S2 S3 D

PID

FNC 88

(PID

control loop)

register each

Receives a data

input and

calculates a

corrective action

to a specified

level based on

PID control

D

)

Note: S1 and S2

use a single

data register

D

)

Note: S3

uses 25

consecutive

data registers

D

)

Note: D

uses a single

data register

PID:

9steps

FX

1S

FX

1N

FX

2N

FX

2NC

PULSE-P

16 BIT OPERATION

32 BIT OPERATION

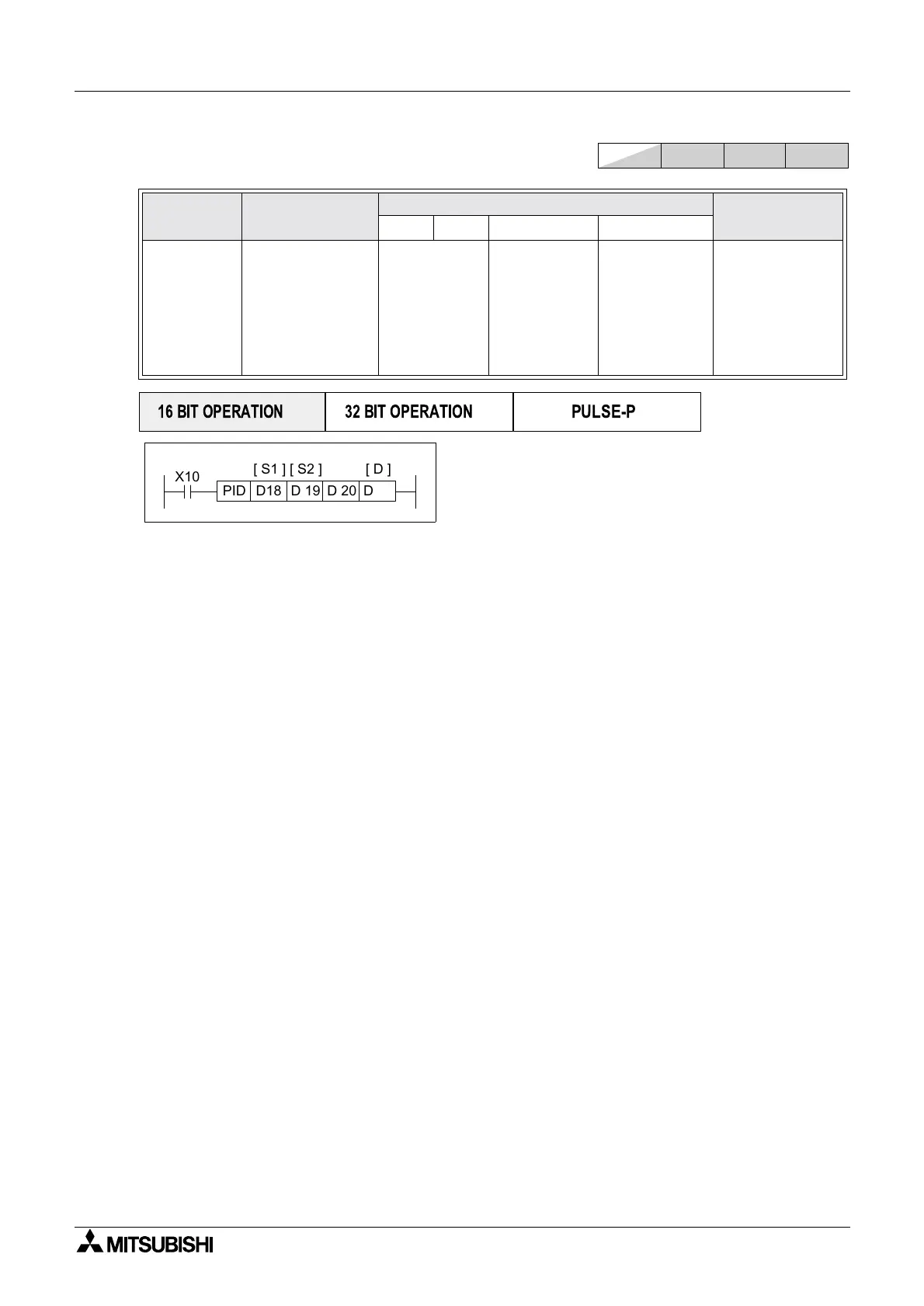

X10

D 19D18PID

[ S1 ] [ S2 ] [ D ]

D 20 D 46

[ S3 ]

Loading...

Loading...